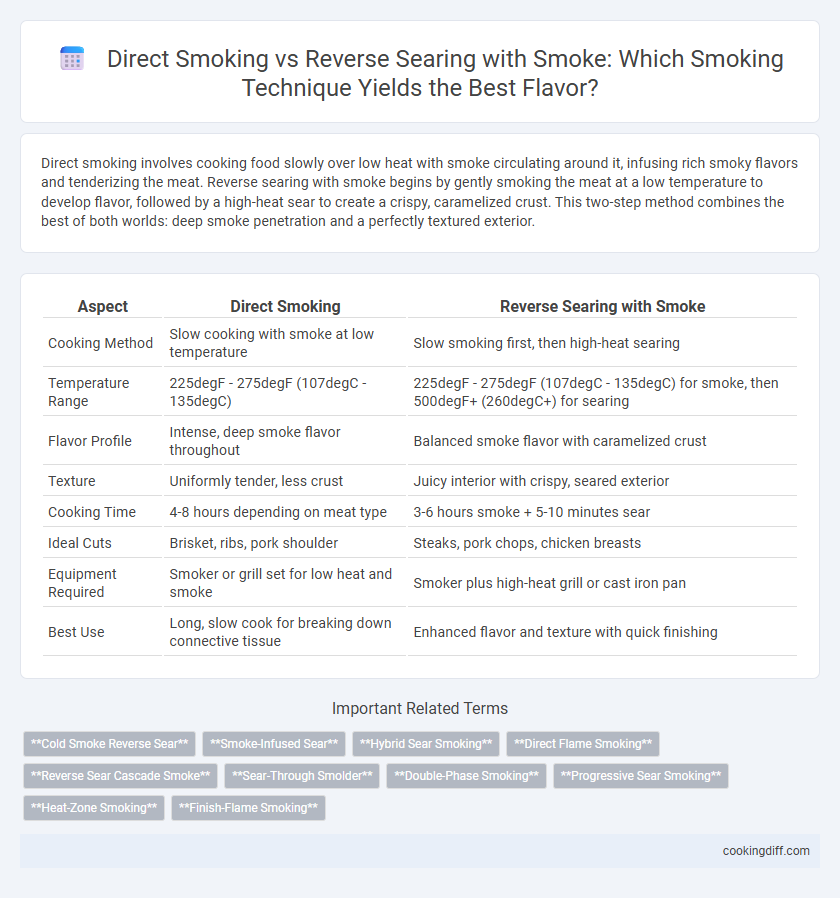

Direct smoking involves cooking food slowly over low heat with smoke circulating around it, infusing rich smoky flavors and tenderizing the meat. Reverse searing with smoke begins by gently smoking the meat at a low temperature to develop flavor, followed by a high-heat sear to create a crispy, caramelized crust. This two-step method combines the best of both worlds: deep smoke penetration and a perfectly textured exterior.

Table of Comparison

| Aspect | Direct Smoking | Reverse Searing with Smoke |

|---|---|---|

| Cooking Method | Slow cooking with smoke at low temperature | Slow smoking first, then high-heat searing |

| Temperature Range | 225degF - 275degF (107degC - 135degC) | 225degF - 275degF (107degC - 135degC) for smoke, then 500degF+ (260degC+) for searing |

| Flavor Profile | Intense, deep smoke flavor throughout | Balanced smoke flavor with caramelized crust |

| Texture | Uniformly tender, less crust | Juicy interior with crispy, seared exterior |

| Cooking Time | 4-8 hours depending on meat type | 3-6 hours smoke + 5-10 minutes sear |

| Ideal Cuts | Brisket, ribs, pork shoulder | Steaks, pork chops, chicken breasts |

| Equipment Required | Smoker or grill set for low heat and smoke | Smoker plus high-heat grill or cast iron pan |

| Best Use | Long, slow cook for breaking down connective tissue | Enhanced flavor and texture with quick finishing |

Introduction: Exploring Smoking Techniques in Cooking

Direct smoking involves exposing food to smoke and heat simultaneously, infusing rich smoky flavors while cooking the food through. Reverse searing with smoke starts by slowly smoking the food at low temperatures to develop flavor and tenderness, followed by a high-heat sear to create a crisp, caramelized crust. Both techniques enhance taste and texture, offering distinct approaches to mastering smoky cuisine.

Understanding Direct Smoking: Method and Benefits

What distinguishes direct smoking from reverse searing with smoke in cooking? Direct smoking involves cooking food slowly over low heat with smoke exposure, enhancing flavor and tenderness. This method infuses a rich smoky aroma while retaining moisture, making it ideal for meats like brisket and ribs.

The Science Behind Reverse Searing with Smoke

Reverse searing with smoke enhances flavor by slowly cooking meat at low temperatures, allowing smoke to penetrate deeply before finishing with a high-heat sear that creates a Maillard crust. This technique preserves juiciness and intensifies smoky aromas compared to direct smoking, which applies heat and smoke simultaneously, potentially drying the exterior.

- Smoke Penetration - Low-temperature smoking in reverse searing maximizes smoke absorption within muscle fibers, enriching meat flavor.

- Maillard Reaction - The high-heat sear at the end promotes complex flavor development through protein and sugar caramelization.

- Moisture Retention - Slow initial cooking reduces moisture loss, maintaining tender and juicy meat texture.

Flavor Profiles: Direct Smoking vs Reverse Searing

Direct smoking infuses meat with a deep, smoky flavor by exposing it to low heat and smoke for an extended time, resulting in a rich, robust taste profile. The continuous smoke penetration enhances the complexity of the outer bark and tender interior.

Reverse searing with smoke combines slow smoking followed by a high-heat sear, producing a balanced flavor with a smoky aroma and a caramelized crust. This method locks in juices while delivering a contrast between the smoky tenderness and the crispy exterior.

Equipment Needed for Each Smoking Technique

Direct smoking requires a smoker or grill capable of maintaining low temperatures and consistent smoke, often using wood chips or chunks directly on the heat source. Reverse searing combines a smoker or grill for the initial slow smoke and a high-temperature grill or cast iron skillet for the final sear, demanding more versatile equipment.

For direct smoking, essential equipment includes a charcoal or pellet smoker, a reliable thermometer, and wood for smoke flavor. Reverse searing needs all direct smoking gear plus a separate searing device like a gas grill or heavy pan to achieve a crispy crust. Temperature control tools are crucial for both methods to ensure proper cooking and flavor development.

Step-by-Step Guide: How to Direct Smoke Meat

Direct smoking involves placing meat directly over the heat source, allowing smoke to envelop the food throughout the cooking process, which imparts a rich, smoky flavor and tender texture. This method requires maintaining a consistent low temperature, ideally between 225degF and 250degF, for even cooking and optimal smoke absorption.

Begin by preparing your smoker or grill, ensuring the wood chips are soaked for 30 minutes to produce steady smoke. Place the meat on the grill grates away from direct flames, monitor internal temperature with a meat thermometer, and smoke until the desired doneness is achieved, usually reaching an internal temperature of 195degF for pulled meats.

Step-by-Step Guide: How to Reverse Sear with Smoke

Start by smoking the meat at a low temperature of 225degF until it reaches an internal temperature of about 110degF, allowing smoke to infuse the flavor deeply. Next, crank the heat on a preheated cast-iron skillet or grill to high and sear the meat for 1-2 minutes per side, creating a caramelized crust. This method combines the smoky aroma from slow smoking with the perfect crust from searing, delivering a flavorful and tender result.

Choosing the Right Meats for Each Smoking Method

Direct smoking works best with smaller, tender cuts like chicken wings and ribs that benefit from quick smoke exposure and heat. Reverse searing suits larger, thicker meats such as brisket or prime rib, allowing slow smoking before a high-temperature finish.

- Direct Smoking - Ideal for meats that cook fast and absorb smoke flavor efficiently, like sausages or fish fillets.

- Reverse Searing - Enhances the texture and flavor of thick cuts by slowly infusing smoke before searing to lock in juices.

- Meat Selection - Choose meat thickness and fat content based on the smoking method to optimize tenderness and flavor development.

Common Mistakes and How to Avoid Them

Many cooks confuse direct smoking with reverse searing, leading to uneven cooking or lack of smoke flavor. Understanding the distinct heat management techniques between these methods is crucial for achieving perfect texture and taste.

- Overexposure to smoke - Excessive smoke can overpower the meat's natural flavor, especially in reverse searing.

- Ignoring internal temperature - Not monitoring meat temperature can cause undercooking in direct smoking or overcooking in reverse searing.

- Skipping the resting period - Failing to rest meat after cooking results in loss of juiciness and uneven flavor distribution.

Mastering these techniques ensures balanced smoke infusion and tender, juicy meat every time.

Related Important Terms

Cold Smoke Reverse Sear

Cold smoke reverse sear combines prolonged exposure to low-temperature smoke with a final high-heat sear to infuse deep smoky flavor while achieving a perfect crust. This cooking technique preserves moisture and tenderness by first cold smoking the meat, then searing it to enhance Maillard reactions without overcooking the interior.

Smoke-Infused Sear

Smoke-infused sear combines the deep flavor penetration of low-temperature smoking with the caramelized crust achieved by high-heat searing, enhancing both taste and texture in meats. This technique preserves the smoky aroma while creating a rich, flavorful outer layer, resulting in a more complex and satisfying culinary experience.

Hybrid Sear Smoking

Hybrid sear smoking combines the precise control of direct high-heat searing with the deep smoky flavors developed in low-and-slow smoking, creating a tender, flavorful crust while preserving juicy interior moisture. This cooking technique leverages initial reverse searing in smoke-infused low temperatures followed by a direct sear to achieve a perfect Maillard reaction, optimizing flavor complexity and texture.

Direct Flame Smoking

Direct flame smoking uses an open flame to quickly infuse food with intense smoky flavors and a crispy exterior, ideal for smaller cuts or thin foods that cook rapidly. This method contrasts with reverse searing, which involves slow smoking followed by high-heat searing to develop a caramelized crust while maintaining internal juiciness.

Reverse Sear Cascade Smoke

The Reverse Sear Cascade Smoke technique enhances flavor by slowly infusing smoke during the initial low-temperature cooking phase, followed by a high-heat sear that locks in juiciness and creates a caramelized crust. This method contrasts with direct smoking by providing more control over smoke penetration and texture, resulting in a tender, smoky profile with a perfectly seared finish.

Sear-Through Smolder

Sear-through smolder in cooking combines the intense heat of direct smoking with low-temperature smoke infusion, creating a caramelized crust while penetrating deep, smoky flavors. This technique optimizes Maillard reaction for savory texture without sacrificing the nuanced essence of aromatic wood smoke typically achieved in reverse searing with smoke.

Double-Phase Smoking

Double-phase smoking combines direct smoking with reverse searing to enhance flavor and texture by first slow-cooking meat with wood smoke at low temperatures, then finishing with high-heat searing to develop a crispy crust. This technique optimizes smoke penetration and Maillard reaction, resulting in tender, smoky, and caramelized dishes ideal for brisket, ribs, and steaks.

Progressive Sear Smoking

Progressive sear smoking combines slow, indirect smoking with a final high-heat sear to enhance flavor and texture in meats by gradually rendering fat and caramelizing the crust. This technique optimizes smoke penetration and Maillard reaction development, delivering a tender interior with a crispy, flavorful outer layer.

Heat-Zone Smoking

Heat-zone smoking relies on precise temperature control by dividing the grill into distinct heat zones, enabling direct smoking at lower temperatures for slow cooking and reverse searing with smoke by finishing meat over high heat to develop a flavorful crust. This method balances smoky flavor infusion and Maillard reaction, enhancing tenderness and flavor complexity in smoked meats.

Direct Smoking vs Reverse Searing with Smoke for cooking technique. Infographic

cookingdiff.com

cookingdiff.com