Traditional smoked meat involves cooking the meat slowly over indirect heat with smoke from wood chips, enhancing flavor while tenderizing the meat. Reverse smoked meat starts by cooking the meat indirectly without smoke and finishes with direct exposure to smoke, producing a crisp bark and deep smoky aroma. Both methods deliver rich, smoky flavors but differ in texture and smoke intensity.

Table of Comparison

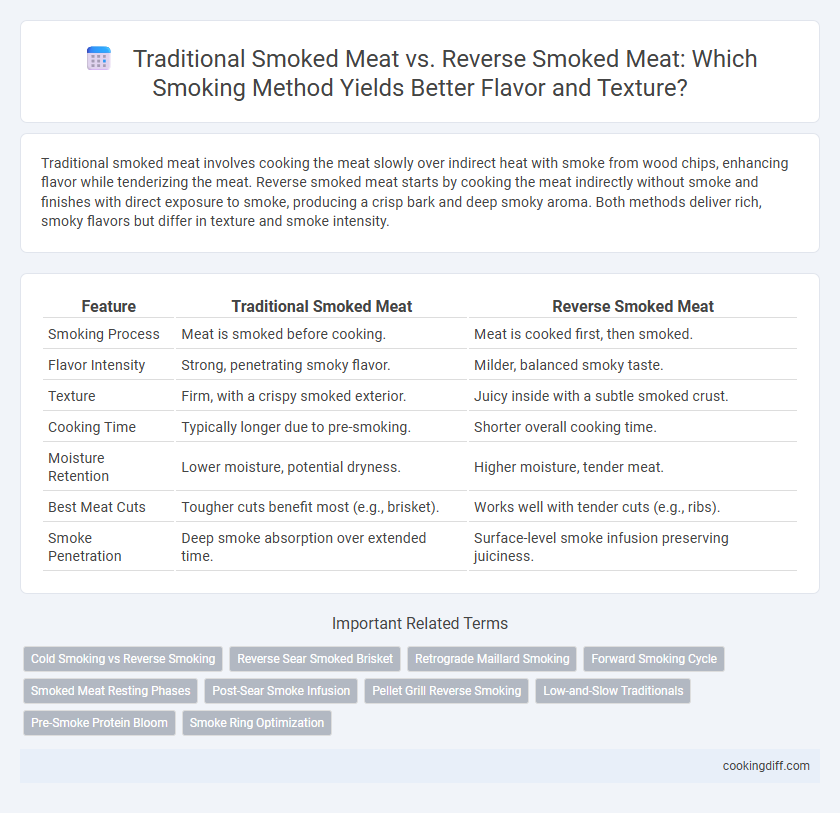

| Feature | Traditional Smoked Meat | Reverse Smoked Meat |

|---|---|---|

| Smoking Process | Meat is smoked before cooking. | Meat is cooked first, then smoked. |

| Flavor Intensity | Strong, penetrating smoky flavor. | Milder, balanced smoky taste. |

| Texture | Firm, with a crispy smoked exterior. | Juicy inside with a subtle smoked crust. |

| Cooking Time | Typically longer due to pre-smoking. | Shorter overall cooking time. |

| Moisture Retention | Lower moisture, potential dryness. | Higher moisture, tender meat. |

| Best Meat Cuts | Tougher cuts benefit most (e.g., brisket). | Works well with tender cuts (e.g., ribs). |

| Smoke Penetration | Deep smoke absorption over extended time. | Surface-level smoke infusion preserving juiciness. |

Origins of Traditional Smoked Meat

Traditional smoked meat originated centuries ago as a preservation method used by indigenous cultures and early settlers to extend the shelf life of meat using natural wood smoke. This technique typically involves exposing meat to low heat and smoke for several hours, imparting distinctive flavors and tenderizing the meat. The use of hardwoods like hickory, mesquite, and oak is essential in traditional smoking to achieve the characteristic smoky aroma and taste.

Introduction to Reverse Smoked Meat Techniques

Reverse smoked meat involves cooking the meat at a low temperature initially before applying direct smoke toward the end of the process, which enhances flavor absorption and tenderness. This method contrasts with traditional smoked meat, where smoking occurs at the beginning, often exposing the meat to prolonged smoke and heat. Reverse smoking techniques help achieve a more balanced smoky flavor while maintaining juiciness and texture in cuts like brisket and pork shoulder.

Key Differences Between Traditional and Reverse Smoking

Traditional smoked meat involves placing the meat above the heat source, allowing it to cook slowly through indirect heat and absorb smoky flavors gradually. Reverse smoked meat uses a method where the meat is cooked over indirect heat first and then exposed to smoke at the end for a shorter time to enhance flavor.

Key differences between traditional and reverse smoking include the cooking order, temperature control, and smoke exposure duration. Traditional smoking relies on low and slow heat throughout the process, resulting in tender, deeply infused smoky meat. Reverse smoking separates cooking and smoking phases, offering more control over texture and a pronounced smoky crust without prolonged smoke exposure.

Flavor Profiles: Traditional vs Reverse Smoked Meat

Traditional smoked meat develops a deep, robust smoky flavor by exposing the meat directly to smoke and heat, often resulting in a crisp bark and pronounced smoky notes. This method enhances the meat's natural taste with complex layers of char and wood-derived flavors, commonly associated with hardwoods like hickory or oak.

Reverse smoked meat, which involves slow cooking before applying smoke at lower temperatures, yields a milder smoke infusion and tender texture. The flavor profile is subtler and more balanced, highlighting the meat's juiciness while imparting delicate smoky undertones without overwhelming the palate.

Texture and Moisture Retention Compared

How does texture and moisture retention differ between traditional smoked meat and reverse smoked meat? Traditional smoked meat often develops a firmer texture with a pronounced smoky bark due to longer exposure to dry heat, which can sometimes lead to moisture loss. Reverse smoked meat uses a slower initial cooking phase followed by smoking, resulting in juicier, more tender meat with enhanced moisture retention and a less rigid crust.

Preparation Processes and Equipment Needed

Traditional smoked meat involves exposing the meat to smoke from burning wood at a low temperature over a long period, typically using smokers like offset or vertical smokers. Reverse smoked meat requires cooking the meat first through indirect heat before finishing it in the smoker, often using equipment that allows precise temperature control such as pellet smokers.

- Traditional Smoking Process - Meat is placed above the heat source and slowly infused with smoke over several hours to develop flavor and tenderness.

- Reverse Smoking Process - Meat is initially cooked at a higher temperature via indirect heat before being smoked at a lower temperature to add smoky flavor and a dark crust.

- Equipment Needed - Traditional smoking typically utilizes offset smokers or charcoal grills, while reverse smoking often requires pellet grills or smokers with dual temperature zones for controlled cooking.

Cooking Times and Temperature Control

Traditional smoked meat relies on longer cooking times at lower temperatures to infuse flavor and tenderize the meat gradually. Reverse smoked meat uses higher initial temperatures to sear the exterior before slow smoking, resulting in a different texture and flavor profile.

- Cooking Time Difference - Traditional smoking typically takes 6 to 12 hours, while reverse smoking can reduce total time by 1 to 3 hours.

- Temperature Control - Maintaining 225degF to 250degF is common in traditional methods, whereas reverse smoking starts at 300degF to 350degF before dropping to traditional levels.

- Flavor Development - Slow, consistent heat in traditional smoking enhances deep smoke penetration compared to the quicker crust formation in reverse smoking.

Optimal smoking requires balancing time and temperature to achieve desired tenderness and smoky flavor.

Health Implications of Each Smoking Method

| Smoking Method | Health Implications |

|---|---|

| Traditional Smoked Meat | Exposes meat directly to smoke, leading to higher concentrations of polycyclic aromatic hydrocarbons (PAHs) and heterocyclic amines (HCAs), which are linked to increased cancer risk. Prolonged exposure to high temperatures may also cause formation of harmful compounds. It often results in a stronger smoky flavor accompanied by potentially elevated toxin levels. |

| Reverse Smoked Meat | Involves indirect smoking by first cooking the meat before exposing it to smoke, reducing the time meat is exposed to harmful combustion byproducts. This method tends to produce fewer carcinogenic compounds while maintaining flavor, offering a potentially healthier alternative to traditional smoking. Temperature control during reverse smoking minimizes harmful chemical formation. |

Best Meat Cuts for Traditional and Reverse Smoking

Traditional smoked meat excels with tougher cuts like brisket and pork shoulder that benefit from long, slow cooking to break down connective tissue. Reverse smoking suits leaner cuts such as ribs and tenderloin, allowing for a gradual flavor development before finishing with smoke.

- Brisket - Ideal for traditional smoking due to its fat content and connective tissue that melts into tender, flavorful meat over hours.

- Pork Shoulder - Perfect for traditional smoking as the low and slow method tenderizes this tougher cut while infusing smoky flavor.

- Ribs - Best for reverse smoking to enhance tenderness and maintain juiciness by applying indirect heat before adding smoky flavor at the end.

Related Important Terms

Cold Smoking vs Reverse Smoking

Cold smoking involves exposing meat to smoke at temperatures between 68-86degF (20-30degC) to infuse flavor without cooking, preserving tenderness and moisture, whereas reverse smoking uses higher temperatures to cook the meat first before smoking, enhancing flavor penetration and creating a firmer texture. Cold smoked meats like salmon or ham retain a delicate smoky aroma ideal for preservation, while reverse smoking is commonly applied to tougher meats, intensifying smokiness and ensuring thorough cooking.

Reverse Sear Smoked Brisket

Reverse seared smoked brisket involves slow smoking the meat at a low temperature before finishing it with a high-heat sear, enhancing tenderness while creating a flavorful crust. This method contrasts with traditional smoked meat, which is typically cooked entirely at low temperatures, often resulting in a less pronounced bark and slightly different texture.

Retrograde Maillard Smoking

Retrograde Maillard smoking enhances flavor by applying heat indirectly, allowing the Maillard reaction to occur on the meat's surface after initial smoking, creating a deeper, caramelized crust compared to traditional smoked meat. This method intensifies savory notes and improves texture by minimizing direct smoke penetration, resulting in a tender, aromatic finish prized in gourmet barbecue preparation.

Forward Smoking Cycle

Traditional smoked meat uses the forward smoking cycle, where smoke is introduced directly into the cooking chamber, infusing meat with distinct smoky flavors through prolonged exposure. This method typically results in deeper smoke penetration but requires careful temperature control to prevent over-smoking or bitterness.

Smoked Meat Resting Phases

Traditional smoked meat requires a longer resting phase at lower temperatures to allow the smoke flavors to fully penetrate and the juices to redistribute evenly. Reverse smoked meat benefits from a shorter resting period due to its initial low-temperature smoke and higher finishing heat, which preserves moisture while intensifying bark formation.

Post-Sear Smoke Infusion

Post-sear smoke infusion in traditional smoked meat involves applying smoke before or during the searing process, infusing deep, robust flavors throughout the meat's surface. Reverse smoked meat employs smoke after searing, preserving a tender crust while allowing a more subtle, aromatic smoke penetration, enhancing juiciness and complexity.

Pellet Grill Reverse Smoking

Pellet grill reverse smoking enhances meat preparation by cooking the meat slowly with indirect heat, preserving juiciness and infusing deep smoky flavors compared to traditional smoked meat, which often exposes meat to direct heat that can dry it out. This method provides a precise temperature control and consistent smoke distribution, resulting in tender, evenly smoked meat with a rich, complex taste profile.

Low-and-Slow Traditionals

Low-and-slow traditional smoked meat preparation relies on indirect heat and extended cooking times, allowing smoke to penetrate deeply for rich, complex flavors and tender texture. In contrast, reverse smoked meat starts with high heat to sear the exterior before low-and-slow smoking, which locks in juices and enhances moisture retention while maintaining the smoky profile.

Pre-Smoke Protein Bloom

Traditional smoked meat relies on direct exposure to smoke and heat, enhancing the pre-smoke protein bloom by forming a flavorful crust essential for moisture retention. Reverse smoked meat technique begins with low heat and extended smoke time, promoting a more even protein coagulation and improved tenderness through gradual collagen breakdown.

Traditional Smoked Meat vs Reverse Smoked Meat for meat preparation. Infographic

cookingdiff.com

cookingdiff.com