Traditional smokers provide direct heat and smoke, creating distinct hot and cool zones that require skillful temperature management for even cooking. Reverse flow smokers utilize a baffle to redirect heat and smoke beneath the cooking surface, promoting uniform heat distribution and enhanced smoke absorption in the meat. Choosing between these smokers depends on the desired control level, cooking consistency, and flavor intensity for your smoked dishes.

Table of Comparison

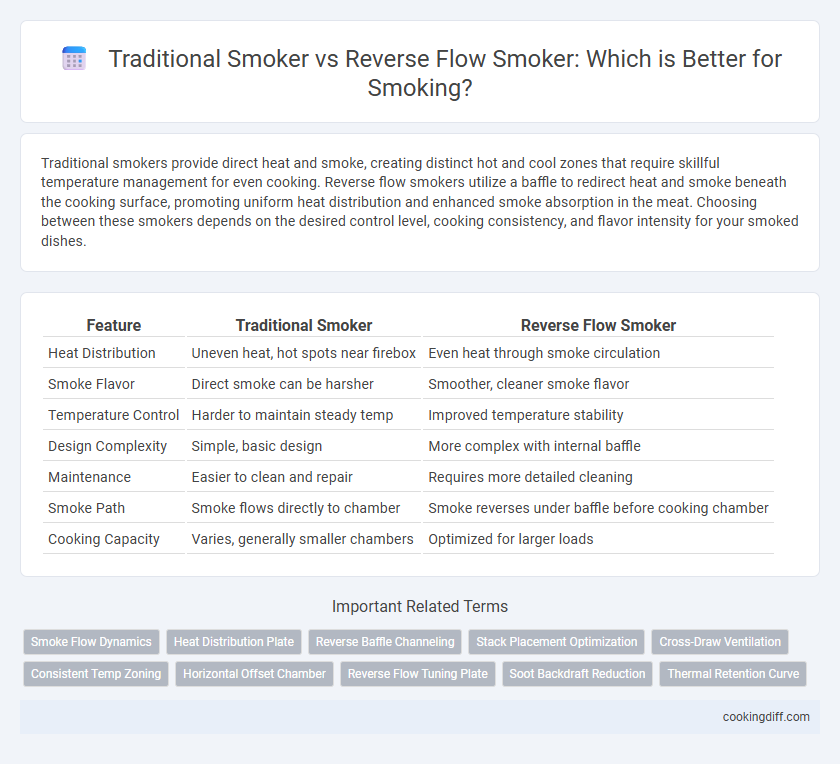

| Feature | Traditional Smoker | Reverse Flow Smoker |

|---|---|---|

| Heat Distribution | Uneven heat, hot spots near firebox | Even heat through smoke circulation |

| Smoke Flavor | Direct smoke can be harsher | Smoother, cleaner smoke flavor |

| Temperature Control | Harder to maintain steady temp | Improved temperature stability |

| Design Complexity | Simple, basic design | More complex with internal baffle |

| Maintenance | Easier to clean and repair | Requires more detailed cleaning |

| Smoke Path | Smoke flows directly to chamber | Smoke reverses under baffle before cooking chamber |

| Cooking Capacity | Varies, generally smaller chambers | Optimized for larger loads |

Introduction: Understanding Traditional and Reverse Flow Smokers

Traditional smokers and reverse flow smokers are popular types of barbecue smokers with distinct design features impacting temperature control and smoke distribution. Understanding the differences helps in choosing the ideal smoker for optimal flavor and even cooking.

- Traditional smoker - Uses a water pan between the firebox and cooking chamber to regulate temperature and moisture.

- Reverse flow smoker - Incorporates a baffle that directs heat and smoke under the cooking surface before reversing direction.

- Heat distribution - Reverse flow smokers offer more consistent heat and smoke circulation across the cooking chamber compared to traditional smokers.

Selecting between these smokers depends on the desired cooking style, temperature stability, and flavor profile.

Design Differences: Traditional vs Reverse Flow Smokers

What are the key design differences between traditional smokers and reverse flow smokers? Traditional smokers feature a straightforward firebox where heat and smoke travel directly to the cooking chamber, often leading to uneven heat distribution. Reverse flow smokers incorporate a baffle system that directs heat and smoke to flow under the cooking grates before reversing direction, promoting more consistent temperature and smoke exposure across the cooking surface.

Heat and Smoke Circulation Mechanics

Traditional smokers rely on a direct heat source, causing uneven temperature zones due to smoke and heat rising and escaping quickly. Reverse flow smokers feature a baffle system that forces heat and smoke to circulate beneath a sealed plate, promoting even heat distribution and consistent smoke flow.

- Traditional smoker heat pattern - Heat rises directly above the firebox, creating hotter spots near the source and cooler zones farther away.

- Reverse flow circulation - Heat travels under a baffle plate, dispersing evenly before reversing direction and exiting, ensuring uniform cooking temperatures.

- Smoke management - Reverse flow smokers retain smoke longer within the cooking chamber, enhancing flavor absorption compared to the faster smoke exit in traditional designs.

Temperature Control and Consistency

Traditional smokers use a direct heat flow that can cause temperature spikes, while reverse flow smokers distribute heat evenly through a baffle system, resulting in more consistent temperature control. Maintaining steady temperatures in reverse flow smokers makes them ideal for low and slow smoking techniques.

- Temperature Stability - Reverse flow smokers offer better heat retention and uniform temperature across the cooking chamber compared to traditional smokers.

- Heat Distribution - Traditional smokers often have hot spots due to direct heat exposure, whereas reverse flow smokers use a baffle plate to diffuse heat evenly.

- Fuel Efficiency - Reverse flow smokers generally require less fuel to maintain consistent temperatures because of their efficient design.

Smoke Flavor Profiles: Which Smoker Excels?

Traditional smokers produce a deep, intense smoke flavor by allowing smoke to directly contact the meat, resulting in a robust and sometimes stronger smoky profile. Reverse flow smokers create a more even heat distribution and milder smoke flavor by channeling smoke under a baffle before it reaches the cooking chamber.

When evaluating smoke flavor profiles, traditional smokers excel in imparting bold, pronounced smokiness ideal for those who prefer a strong charred taste. Reverse flow smokers offer a balanced, smoother smoke flavor with less chance of bitter creosote buildup, making them suitable for delicate meats and longer smoking sessions. The choice depends on whether a user prioritizes intense smoke flavor or consistent, subtle smokiness.

Cooking Times and Fuel Efficiency Comparison

Traditional smokers typically require longer cooking times due to uneven heat distribution, which can lead to inconsistent results and increased fuel consumption. In contrast, reverse flow smokers use a baffle system that redirects heat and smoke for more uniform cooking, reducing the overall cooking duration.

Reverse flow smokers generally offer better fuel efficiency by maintaining a steady temperature and utilizing heat more effectively, resulting in less wood or charcoal usage. Traditional smokers often demand more frequent fuel additions, making them less efficient for prolonged smoking sessions.

Versatility and Cooking Capacity

| Smoker Type | Versatility | Cooking Capacity |

| Traditional Smoker | Best suited for low and slow smoking with limited temperature control, ideal for classic barbecue styles. | Typically has a smaller cooking area, focused on smoking a few large cuts at once, limiting large gatherings. |

| Reverse Flow Smoker | Offers greater versatility by enabling better heat distribution and temperature control, supporting a variety of smoking and grilling techniques. | Features a larger cooking capacity with even heat across the chamber, accommodating multiple racks or larger quantities efficiently. |

Ease of Use and Maintenance Requirements

Traditional smokers are generally easier to use for beginners due to their straightforward design and direct heat source. They require regular monitoring to maintain consistent temperature, which can be challenging for novices.

Reverse flow smokers offer more even heat distribution and smoke circulation, reducing the need for frequent adjustments during cooking. Maintenance involves cleaning the internal baffle and drip pan, which can be more complex but enhances long-term performance.

Pros and Cons of Traditional Smokers

Traditional smokers provide direct heat and smoke, creating a robust flavor profile favored by many barbecue enthusiasts. They tend to have hot spots, requiring frequent monitoring and adjustments to maintain consistent cooking temperatures. While simpler in design, traditional smokers may produce uneven cooking results compared to reverse flow smokers, which offer more uniform heat distribution.

Related Important Terms

Smoke Flow Dynamics

Traditional smokers utilize a direct smoke flow where heat and smoke travel horizontally across the cooking chamber, often resulting in hotspots and uneven cooking. Reverse flow smokers incorporate a baffle that redirects the smoke under the cooking surface before it rises, promoting consistent heat distribution and more uniform smoke exposure for better flavor penetration.

Heat Distribution Plate

Traditional smokers use a simple heat distribution plate that directs heat from the firebox to the cooking chamber but often results in uneven temperature hotspots. Reverse flow smokers incorporate a specialized baffle plate that forces heat and smoke to travel under the plate before reaching the food, ensuring more consistent heat distribution and better smoke circulation throughout the cooking area.

Reverse Baffle Channeling

Reverse flow smokers utilize a reverse baffle design that directs heat and smoke underneath the baffle and back over the meat, promoting even heat distribution and enhanced smoke circulation compared to traditional smokers. This reverse baffle channeling reduces hot spots, maintains consistent temperature, and improves flavor penetration by ensuring smoke flows uniformly across the cooking chamber.

Stack Placement Optimization

Traditional smokers place the stack directly opposite the firebox, creating a straightforward heat and smoke path but potentially causing uneven temperature distribution and hot spots. Reverse flow smokers position the stack on the same side as the firebox, forcing heat and smoke to flow beneath a sealed baffle plate before exiting, which promotes more consistent heat circulation and improved smoking efficiency.

Cross-Draw Ventilation

Traditional smokers rely on direct airflow through the firebox, which can cause uneven heat distribution and smoke flow, whereas reverse flow smokers utilize a cross-draw ventilation system that directs smoke and heat across the cooking chamber before exiting, ensuring more consistent temperature and enhanced smoke flavor infusion. The cross-draw ventilation in reverse flow smokers also minimizes flare-ups and maintains moisture, making it ideal for longer smoking sessions and better meat quality.

Consistent Temp Zoning

Reverse flow smokers provide more consistent temperature zoning by circulating heat evenly underneath the cooking surface, reducing hot spots and allowing precise control over cooking. Traditional smokers often struggle with uneven heat distribution, leading to fluctuating temperature zones that can compromise smoke quality and cooking results.

Horizontal Offset Chamber

Traditional smokers rely on a vertical offset chamber that directs heat and smoke upwards through the cooking chamber, often causing uneven temperature distribution and requiring more frequent monitoring. Reverse flow smokers feature a horizontal offset chamber with a baffle that forces smoke and heat to travel across the cooking area before rising, promoting consistent heat distribution and improved smoke flavor throughout the meat.

Reverse Flow Tuning Plate

The reverse flow tuning plate in reverse flow smokers evenly distributes heat and smoke across the cooking chamber, preventing hot spots and ensuring consistent temperature control essential for optimal meat smoking. Traditional smokers lack this feature, often resulting in uneven heat distribution, which can cause inconsistent cooking and less flavorful results compared to the precise smoke circulation facilitated by the reverse flow system.

Soot Backdraft Reduction

Traditional smokers often experience soot buildup and backdraft issues due to direct smoke flow, which can result in inconsistent cooking temperatures and flavor contamination. Reverse flow smokers minimize soot backdraft by directing smoke evenly over a baffle plate before circulating it to the cooking chamber, ensuring cleaner combustion and more uniform heat distribution.

Traditional Smoker vs Reverse Flow Smoker for smoking. Infographic

cookingdiff.com

cookingdiff.com