Plastic containers offer a lightweight and cost-effective option for sous vide cooking but may lack the durability and heat resistance of polycarbonate tanks. Polycarbonate tanks provide superior clarity, enhanced durability, and better insulation, ensuring consistent temperature control during long cooking sessions. Choosing between them depends on budget, frequency of use, and the importance of maintaining precise sous vide conditions.

Table of Comparison

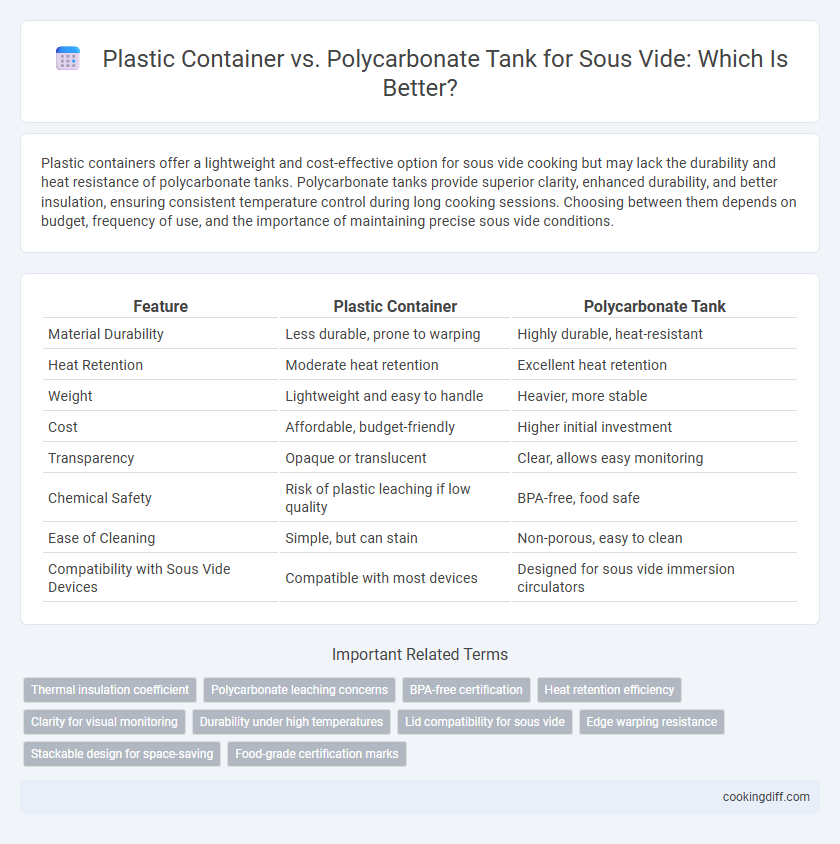

| Feature | Plastic Container | Polycarbonate Tank |

|---|---|---|

| Material Durability | Less durable, prone to warping | Highly durable, heat-resistant |

| Heat Retention | Moderate heat retention | Excellent heat retention |

| Weight | Lightweight and easy to handle | Heavier, more stable |

| Cost | Affordable, budget-friendly | Higher initial investment |

| Transparency | Opaque or translucent | Clear, allows easy monitoring |

| Chemical Safety | Risk of plastic leaching if low quality | BPA-free, food safe |

| Ease of Cleaning | Simple, but can stain | Non-porous, easy to clean |

| Compatibility with Sous Vide Devices | Compatible with most devices | Designed for sous vide immersion circulators |

Introduction: Choosing the Right Sous Vide Container

Selecting the right container for sous vide cooking is essential for temperature stability and durability. Plastic containers made from BPA-free polypropylene offer lightweight options with good heat resistance, while polycarbonate tanks provide superior clarity and impact resistance, ideal for precise cooking control. Understanding the thermal properties and safety standards of each material helps ensure consistent results and food safety during sous vide preparation.

Material Overview: Plastic vs Polycarbonate

Plastic containers for sous vide are typically made from polypropylene or BPA-free polyethylene, offering lightweight and cost-effective options suitable for home cooking. Polycarbonate tanks are more durable and heat-resistant, providing excellent clarity and structural stability under prolonged high temperatures. While plastic containers may warp over time, polycarbonate tanks maintain shape and safety, making them ideal for professional or frequent sous vide use.

Heat Retention and Insulation Comparison

Plastic containers generally provide better heat retention due to their thicker walls and insulating properties compared to polycarbonate tanks. Polycarbonate tanks offer clear visibility but tend to lose heat faster, requiring more frequent temperature adjustments during sous vide cooking.

- Heat Retention - Plastic containers maintain stable temperatures longer, reducing energy consumption.

- Insulation - Thicker plastic walls create a natural barrier against heat loss, enhancing cooking efficiency.

- Temperature Stability - Polycarbonate tanks may require additional insulation accessories to match the heat retention capabilities of plastic containers.

Choosing a plastic container over a polycarbonate tank improves heat retention and insulation for consistent sous vide cooking results.

Durability and Longevity

| Plastic containers used in sous vide cooking offer lightweight convenience but may degrade faster over time due to repeated exposure to heat and water, leading to potential warping or cracking. |

| Polycarbonate tanks provide superior durability and longevity, resisting heat and physical impact while maintaining structural integrity for extended sous vide use. |

| The higher heat resistance and toughness of polycarbonate materials make them a preferred choice for sous vide enthusiasts seeking long-term, reliable cooking vessels. |

Safety: Food-Grade and BPA Concerns

Plastic containers used for sous vide cooking are often made from food-grade polypropylene, which is BPA-free and safe for repeated heating. Polycarbonate tanks, while durable and heat-resistant, may contain BPA unless specifically labeled as BPA-free, raising potential health concerns.

Food-grade plastic containers ensure no harmful chemicals leach into the food during long cooking times at controlled temperatures. Polycarbonate tanks provide excellent durability and thermal stability but require careful verification of their BPA status to guarantee food safety. Choosing BPA-free, FDA-approved containers is essential for optimal sous vide safety and health protection.

Transparency and Monitoring Water Levels

Polycarbonate tanks offer superior transparency compared to typical plastic containers, allowing clear visibility of water levels during sous vide cooking. This enhanced clarity makes it easier to monitor and maintain the ideal water level, ensuring precise temperature control for consistent results.

- Polycarbonate Transparency - Provides clear, durable walls that facilitate easy water level monitoring without opening the container.

- Plastic Container Limitations - Often less transparent, making it difficult to visually track water levels accurately.

- Water Level Maintenance - Clear visibility minimizes the risk of water evaporation affecting cooking time and temperature stability.

Compatibility with Sous Vide Equipment

Plastic containers often provide versatile compatibility with various sous vide immersion circulators due to their lightweight design and heat resistance. Polycarbonate tanks offer enhanced durability and stable thermal performance, making them suitable for extended sous vide cooking sessions.

- Plastic Container Versatility - Lightweight plastic containers accommodate a wide range of sous vide equipment sizes and shapes for flexible cooking setups.

- Polycarbonate Tank Durability - Polycarbonate tanks resist heat deformation and maintain integrity during long sous vide baths, ensuring consistent cooking results.

- Equipment Stability - Polycarbonate tanks often feature integrated clips or mounts that secure sous vide circulators firmly, improving safety and precision.

Cleaning and Maintenance

Plastic containers used for sous vide cooking often require gentle cleaning methods to avoid scratching and chemical degradation, which can harbor bacteria over time. Regular hand washing with mild soap preserves the container's integrity and prolongs its lifespan.

Polycarbonate tanks offer higher durability and are easier to sanitize due to their non-porous surface that resists staining and odor retention. These tanks typically withstand dishwasher cleaning, simplifying maintenance while ensuring hygienic conditions for precise sous vide cooking.

Cost-Effectiveness and Availability

Which option offers better cost-effectiveness and availability for sous vide cooking: plastic containers or polycarbonate tanks? Plastic containers are generally more affordable and widely available from various retailers, making them a budget-friendly choice for home cooks. Polycarbonate tanks, while more durable and suited for professional use, tend to be more expensive and less commonly stocked in general stores.

Related Important Terms

Thermal insulation coefficient

Polycarbonate tanks offer a lower thermal insulation coefficient compared to standard plastic containers, resulting in more efficient heat retention during sous vide cooking. This improved thermal conductivity ensures consistent water temperature, enhancing cooking precision and energy savings.

Polycarbonate leaching concerns

Polycarbonate tanks used in sous vide cooking have raised concerns due to potential BPA leaching, especially at high temperatures, which may pose health risks. Plastic containers made from BPA-free materials like polypropylene offer a safer alternative by minimizing chemical leaching during prolonged aquathermal exposure.

BPA-free certification

Choosing a BPA-free polycarbonate tank for sous vide cooking ensures chemical safety and durability under precise temperature control, while plastic containers without proper BPA-free certification may risk leaching harmful substances. Polycarbonate tanks certified BPA-free provide a reliable, food-safe environment crucial for maintaining the integrity of sous vide cooking temperatures and flavors.

Heat retention efficiency

Polycarbonate tanks offer superior heat retention efficiency for sous vide cooking compared to standard plastic containers due to their thicker walls and better insulating properties. This results in more consistent temperature maintenance and reduced energy consumption during long cooking processes.

Clarity for visual monitoring

Polycarbonate tanks provide superior clarity compared to plastic containers, enabling precise visual monitoring of food during sous vide cooking. This enhanced transparency ensures accurate observation of water level and food positioning for optimal cooking results.

Durability under high temperatures

Polycarbonate tanks offer superior durability under high temperatures compared to plastic containers, maintaining structural integrity and resisting warping during extended sous vide cooking sessions. Plastic containers may soften or deform when exposed to prolonged heat, reducing their lifespan and potentially compromising cooking performance.

Lid compatibility for sous vide

Polycarbonate tanks offer superior lid compatibility for sous vide cooking due to their standardized sizes and durable construction, allowing for airtight seals that maintain consistent temperature control. Plastic containers, while often more affordable, may lack customized lids, leading to heat loss and less efficient cooking performance during extended sous vide sessions.

Edge warping resistance

Polycarbonate tanks offer superior edge warping resistance compared to typical plastic containers, ensuring durability under prolonged exposure to consistent sous vide temperatures. Their robust material composition maintains shape integrity, minimizing deformation and providing stable water circulation for precise temperature control.

Stackable design for space-saving

Polycarbonate tanks offer a stackable design that maximizes kitchen space by allowing multiple units to be securely piled, ideal for sous vide enthusiasts with limited room. Plastic containers generally lack this structural integrity and interlocking features, making them less efficient for compact, organized storage.

Plastic container vs polycarbonate tank for sous vide. Infographic

cookingdiff.com

cookingdiff.com