Sous vide technology offers precise temperature control ideal for consistent fermentation, while bioreactor cooking provides dynamic environment regulation tailored to microbial growth phases. Sous vide's simplicity and stability make it suitable for small-scale or artisanal fermentation, whereas bioreactors excel in scalability and automated monitoring of key parameters such as pH, oxygen, and agitation. Selecting between sous vide and bioreactor methods depends on the scale, complexity, and specific fermentation requirements.

Table of Comparison

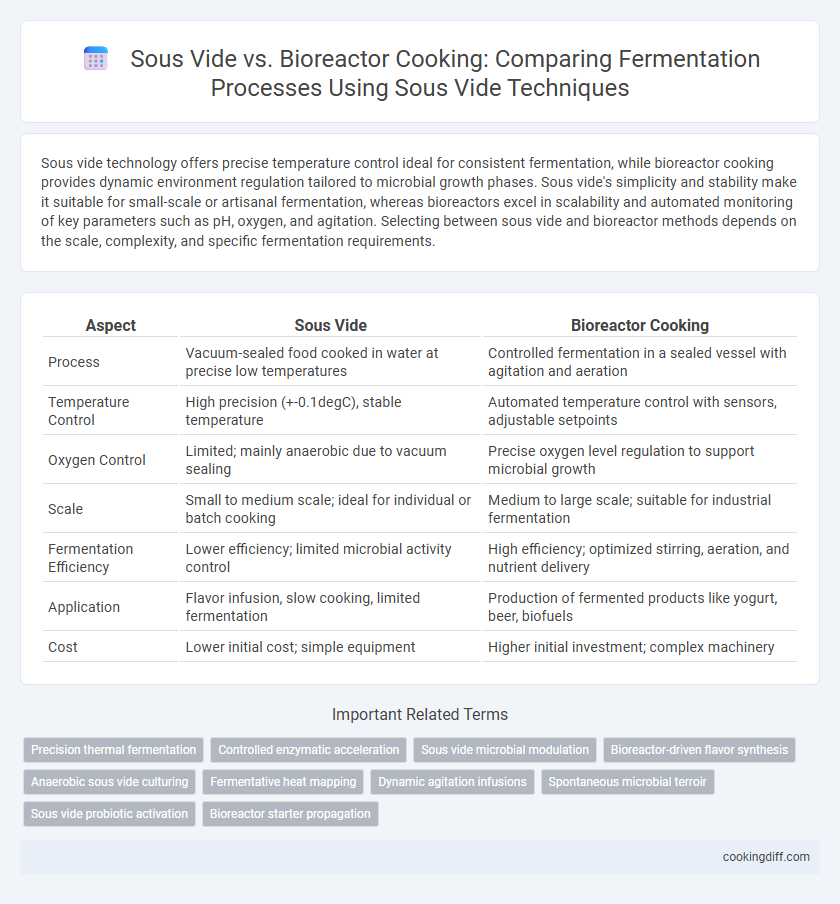

| Aspect | Sous Vide | Bioreactor Cooking |

|---|---|---|

| Process | Vacuum-sealed food cooked in water at precise low temperatures | Controlled fermentation in a sealed vessel with agitation and aeration |

| Temperature Control | High precision (+-0.1degC), stable temperature | Automated temperature control with sensors, adjustable setpoints |

| Oxygen Control | Limited; mainly anaerobic due to vacuum sealing | Precise oxygen level regulation to support microbial growth |

| Scale | Small to medium scale; ideal for individual or batch cooking | Medium to large scale; suitable for industrial fermentation |

| Fermentation Efficiency | Lower efficiency; limited microbial activity control | High efficiency; optimized stirring, aeration, and nutrient delivery |

| Application | Flavor infusion, slow cooking, limited fermentation | Production of fermented products like yogurt, beer, biofuels |

| Cost | Lower initial cost; simple equipment | Higher initial investment; complex machinery |

Introduction to Sous Vide and Bioreactor Cooking

Sous vide is a precise temperature-controlled cooking method using a water bath, traditionally applied to culinary techniques but increasingly explored for fermentation processes. Bioreactor cooking involves controlled microbial fermentation in specialized vessels, optimizing environmental conditions like oxygen, pH, and temperature for large-scale production.

Both methods enhance fermentation by maintaining stable conditions, yet sous vide offers simplicity and cost efficiency for small-batch experiments, while bioreactors provide advanced control and scalability. Understanding their respective mechanisms supports improved fermentation outcomes in food technology and biotechnology sectors.

Overview of Fermentation in Culinary Practices

Fermentation in culinary practices involves controlled microbial growth to develop flavors, textures, and preservation in food products. Sous vide offers precise temperature control, enhancing fermentation consistency in small-scale kitchen settings.

Bioreactor cooking, designed for industrial fermentation, provides large-scale automation, optimal oxygenation, and stringent environmental control, promoting efficient microbial metabolism for mass food production. While sous vide suits artisanal and experimental fermentation with flexible batch sizes, bioreactors deliver scalability and reproducibility critical for commercial food fermentations. The choice between sous vide and bioreactor methods depends on the required volume, process control, and specific culinary fermentation goals.

How Sous Vide Facilitates Fermentation

Sous vide technology enables precise temperature control, creating an optimal environment for fermentation by maintaining consistent heat that accelerates microbial activity. This precision contrasts with bioreactor cooking, which often requires complex monitoring systems to balance temperature, pH, and oxygen levels. By using vacuum-sealed bags, sous vide minimizes contamination risk and preserves the integrity of the fermentation process, resulting in more reliable and flavorful outcomes.

Bioreactor Cooking: Principles and Applications

Bioreactor cooking leverages controlled fermentation environments to optimize microbial growth and enzymatic activity, enabling precise manipulation of temperature, pH, and oxygen levels. This method enhances the production of fermented foods and beverages by maximizing yield and consistency compared to traditional techniques.

In contrast to sous vide, bioreactor systems incorporate continuous monitoring and automated control to maintain ideal conditions for fermentation processes. Applications span from dairy fermentation, such as yogurt and cheese production, to biotechnological synthesis of bioactive compounds and probiotics.

Temperature and pH Control: A Comparative Analysis

Sous vide offers precise temperature control typically within +-0.1degC, providing a stable environment ideal for consistent fermentation processes. Bioreactors advance this by integrating automated pH monitoring and adjustment systems, enabling dynamic regulation crucial for optimizing microbial growth and metabolite production. While sous vide excels in maintaining steady thermal conditions, bioreactors provide comprehensive control over both temperature and pH, enhancing fermentation efficiency and product quality.

Precision and Consistency in Fermentation Outcomes

Sous vide offers exceptional temperature control crucial for consistent fermentation, enabling uniform microbial activity and predictable flavor development. Bioreactors provide advanced environmental regulation, including pH and oxygen levels, which are essential for optimizing fermentation processes at an industrial scale.

- Temperature Precision - Sous vide maintains water temperature within +-0.1degC, ensuring stable fermentation conditions.

- Environmental Control - Bioreactors incorporate sensors to monitor and adjust variables such as pH and dissolved oxygen in real time.

- Consistent Outcomes - Both methods reduce batch variability, but bioreactors excel in scalability and process automation for large-scale fermentation.

Equipment Cost, Accessibility, and Scalability

Sous vide equipment tends to be more affordable and accessible for small-scale fermentation, while bioreactors involve higher initial costs but offer greater scalability for industrial applications. Both methods provide precise temperature control, yet bioreactors are designed for complex microbial cultures requiring strict environmental conditions.

- Equipment Cost - Sous vide devices cost significantly less than bioreactors, making them ideal for experimental or artisanal fermentation projects.

- Accessibility - Sous vide machines are widely available and easy to operate, whereas bioreactors require specialized knowledge and infrastructure.

- Scalability - Bioreactors support large-scale, continuous fermentation with automated monitoring, while sous vide is limited to batch processes and smaller volumes.

Flavor Development: Sous Vide vs Bioreactor Techniques

Sous vide cooking offers precise temperature control that enhances flavor development during fermentation by maintaining consistent heat, whereas bioreactor techniques allow for scalable fermentation with controlled nutrient and oxygen supply. The flavor complexity in sous vide-fermented products often results from extended low-temperature exposure, contrasting with bioreactors' efficient microbial growth and metabolic activity optimization.

- Temperature Precision - Sous vide maintains stable low temperatures ideal for slow enzymatic reactions contributing to nuanced flavors.

- Scalability - Bioreactors enable large-scale fermentation while controlling environmental conditions to maximize flavor compound production.

- Flavor Profiles - Sous vide can develop subtle, complex flavors through gentle heat, while bioreactors promote robust metabolite formation through optimized microbial activity.

Each method offers distinct advantages in flavor development depending on fermentation goals and production scale.

Safety and Hygiene Considerations for Fermented Foods

| Safety and Hygiene in Sous Vide vs Bioreactor Cooking for Fermentation |

| Sous vide cooking ensures precise temperature control, reducing pathogenic bacteria risk in fermented foods, while bioreactors provide sterile, closed environments that minimize contamination during fermentation. Both methods require strict adherence to hygiene protocols; sous vide demands vacuum-sealed packaging to prevent external contamination, whereas bioreactors maintain sterile conditions through controlled inputs and aseptic handling. Effective monitoring of temperature, pH, and microbial activity is essential in both to guarantee safety and consistent product quality. |

Related Important Terms

Precision thermal fermentation

Sous vide cooking provides precise temperature control essential for optimizing microbial growth in fermentation, ensuring consistent product quality through stable thermal environments. Bioreactor cooking offers scalable fermentation with integrated monitoring systems, but sous vide excels in precision thermal fermentation by maintaining exact temperatures critical for enzyme activity and metabolic control.

Controlled enzymatic acceleration

Sous vide offers precise temperature control for enzymatic acceleration in fermentation, ensuring consistent and uniform conditions critical for optimal microbial activity. Bioreactor cooking, while effective for large-scale fermentation, may face challenges in maintaining uniform enzymatic acceleration due to variations in mixing and temperature gradients.

Sous vide microbial modulation

Sous vide technology enables precise temperature control that optimizes microbial growth conditions for fermentation, enhancing flavor profiles and consistency in food products. Unlike bioreactor cooking, sous vide allows for controlled microbial modulation within sealed environments, reducing contamination risks and improving fermentation outcomes.

Bioreactor-driven flavor synthesis

Bioreactor cooking enables precise control over microbial fermentation parameters, optimizing flavor synthesis through tailored temperature, pH, and oxygen levels that surpass the passive heat application of sous vide techniques. This control enhances the production of complex flavor compounds, resulting in more consistent and intensified taste profiles compared to traditional sous vide fermentation.

Anaerobic sous vide culturing

Anaerobic sous vide culturing offers precise temperature control for fermentation processes, ensuring consistent microbial growth and metabolite production, while bioreactor cooking provides scalable, automated environments with enhanced aeration and mixing capabilities. Sous vide's airtight, low-oxygen conditions mimic anaerobic environments crucial for fermenting specific bacteria, making it a cost-effective alternative for small-scale, controlled anaerobic fermentation.

Fermentative heat mapping

Sous vide offers precise temperature control essential for fermentative heat mapping, enabling consistent microbial activity in small-scale fermentation. Bioreactor cooking, designed for large-scale fermentation, integrates dynamic heat distribution and real-time monitoring to optimize metabolic pathways and maximize yield.

Dynamic agitation infusions

Sous vide offers precise temperature control but lacks dynamic agitation, limiting uniform infusion during fermentation; bioreactor cooking integrates continuous dynamic agitation, enhancing nutrient distribution and fermentation consistency. Dynamic agitation infusions in bioreactors optimize mass transfer and microbial activity by maintaining homogeneous conditions, outperforming the static environment of sous vide methods.

Spontaneous microbial terroir

Sous vide offers precise temperature control ideal for consistent fermentation but lacks the dynamic microbial diversity present in bioreactor cooking, which fosters spontaneous microbial terroir development critical for unique flavor profiles. Bioreactor cooking leverages environmental microbial consortia, enhancing complex fermentation outcomes and promoting terroir-driven fermentation biodiversity.

Sous vide probiotic activation

Sous vide cooking ensures precise temperature control, creating an optimal environment for probiotic activation by maintaining steady heat levels that promote beneficial bacterial growth during fermentation processes. Compared to bioreactor cooking, sous vide offers a more accessible and scalable method for enhancing probiotic viability in fermented foods.

Sous vide vs bioreactor cooking for fermentation processes. Infographic

cookingdiff.com

cookingdiff.com