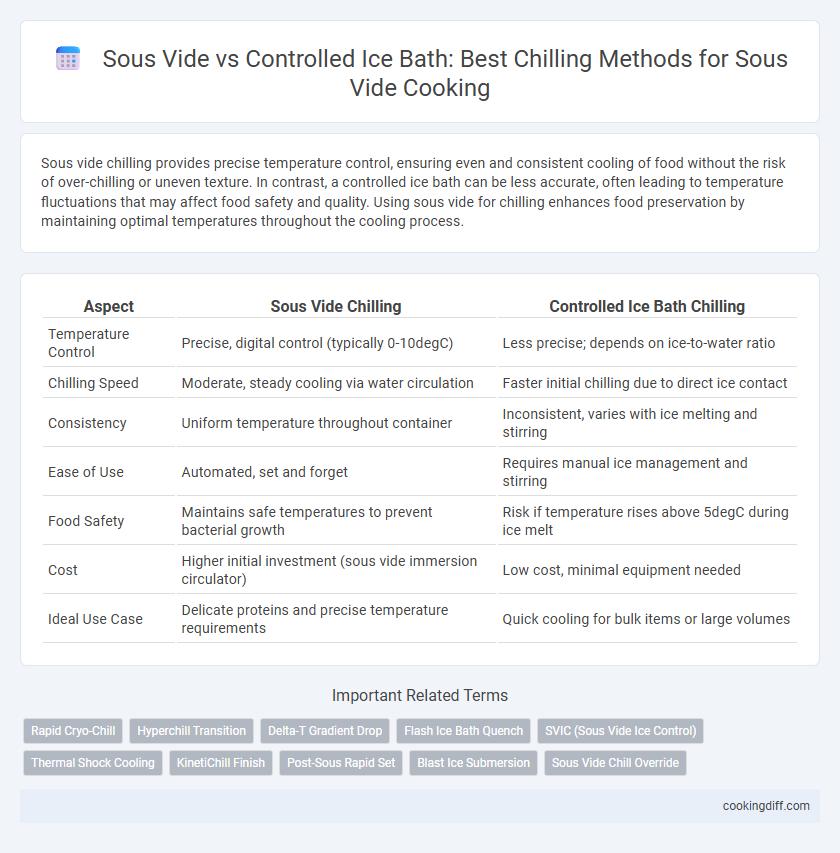

Sous vide chilling provides precise temperature control, ensuring even and consistent cooling of food without the risk of over-chilling or uneven texture. In contrast, a controlled ice bath can be less accurate, often leading to temperature fluctuations that may affect food safety and quality. Using sous vide for chilling enhances food preservation by maintaining optimal temperatures throughout the cooling process.

Table of Comparison

| Aspect | Sous Vide Chilling | Controlled Ice Bath Chilling |

|---|---|---|

| Temperature Control | Precise, digital control (typically 0-10degC) | Less precise; depends on ice-to-water ratio |

| Chilling Speed | Moderate, steady cooling via water circulation | Faster initial chilling due to direct ice contact |

| Consistency | Uniform temperature throughout container | Inconsistent, varies with ice melting and stirring |

| Ease of Use | Automated, set and forget | Requires manual ice management and stirring |

| Food Safety | Maintains safe temperatures to prevent bacterial growth | Risk if temperature rises above 5degC during ice melt |

| Cost | Higher initial investment (sous vide immersion circulator) | Low cost, minimal equipment needed |

| Ideal Use Case | Delicate proteins and precise temperature requirements | Quick cooling for bulk items or large volumes |

Understanding Sous Vide Chilling Techniques

| Method | Temperature Precision | Chilling Speed | Food Quality Impact |

| Sous Vide Chilling | Maintains precise, consistent temperatures often between 0degC to 3degC, reducing temperature fluctuations and ensuring even chilling throughout the food. | Slower compared to ice bath but optimizes texture by preventing thermal shock. | Preserves moisture and texture by controlled cooling, minimizing surface dehydration and maintaining the original quality. |

| Controlled Ice Bath | Less precise temperature control, dependent on ice melt and water agitation, usually between 0degC to 4degC. | Faster chilling process due to direct contact with ice-cold water, rapidly reducing core temperature. | Higher risk of uneven cooling and potential texture degradation caused by thermal shock and surface moisture loss. |

What Is a Controlled Ice Bath?

A controlled ice bath is a precise cooling method used to rapidly chill sous vide-cooked food by submerging it in ice water with monitored temperature. It maintains a consistent temperature to prevent overcooling and ensure optimal food safety and texture.

- Temperature Regulation - Maintains water temperature typically between 0degC and 4degC for effective chilling without freezing.

- Rapid Cooling - Quickly reduces food temperature to safe levels, minimizing bacterial growth risks after sous vide cooking.

- Consistent Results - Provides stable cooling conditions ensuring even texture and quality preservation in food.

Temperature Precision: Sous Vide vs Ice Bath

Sous vide offers unmatched temperature precision by maintaining water at a consistent, programmable temperature, typically within +-0.1degC. In contrast, controlled ice baths usually hover around 0degC but can fluctuate due to melting ice and ambient conditions.

The precise temperature control of sous vide ensures uniform chilling and reduces the risk of partial thawing or bacterial growth. Ice baths, while effective for rapid cooling, lack the fine temperature regulation, leading to uneven chilling. Sous vide's precision is especially beneficial for delicate foods requiring exact cooling thresholds.

Food Safety Considerations

Sous vide cooking offers precise temperature control which enhances food safety during the chilling process by minimizing bacterial growth. Controlled ice baths rapidly reduce food temperature, effectively preventing the growth of harmful pathogens in vacuum-sealed foods.

- Sous vide precision - Maintains consistent temperatures below the danger zone, reducing bacterial proliferation risks.

- Rapid chilling in ice bath - Quickly lowers core temperature to under 41degF (5degC), critical for inhibiting pathogen growth.

- Cross-contamination prevention - Vacuum sealing in sous vide combined with ice bath chilling limits exposure to contaminants.

Combining sous vide cooking with controlled ice bath chilling maximizes food safety by ensuring both precise temperature control and rapid cooling.

Flavor and Texture Impact

Sous vide chilling maintains precise temperature control, preserving the food's flavor and texture by preventing overcooling or waterlogging. Controlled ice baths can cause uneven chilling, which may result in texture degradation and flavor dilution due to excessive moisture absorption. The consistent environment of sous vide ensures optimal retention of juices and tender, uniform textures, enhancing overall sensory quality.

Equipment and Setup Comparison

How does sous vide equipment compare to a controlled ice bath for chilling food? Sous vide devices offer precise temperature control with built-in circulators that maintain consistent cooling environments, while controlled ice baths require manual monitoring and ice replenishment to sustain desired temperatures. The sous vide setup often includes digital interfaces and vacuum sealing options, enhancing convenience and reliability compared to the more basic and hands-on ice bath method.

Time Efficiency: Which Method Cools Faster?

Sous vide chillers typically cool food faster than controlled ice baths due to precise temperature regulation and consistent water circulation. Ice baths rely on manual ice replenishment and have less efficient heat transfer, often requiring 20-30 minutes longer for similar cooling results. Time efficiency in sous vide systems ensures rapid chilling, reducing bacterial growth risks during the cooling phase.

Cost and Resource Implications

Sous vide machines typically require a higher initial investment compared to controlled ice baths but offer precise temperature control that can reduce food waste and improve consistency. Controlled ice baths have lower upfront costs and use minimal energy, making them cost-effective for occasional chilling tasks.

- Sous Vide Machine Cost - High initial purchase price with ongoing electricity use for water circulation and heating.

- Ice Bath Resource Use - Utilizes ice and water with negligible energy consumption but requires frequent ice replenishment.

- Operational Efficiency - Sous vide systems reduce labor and time for chilling by maintaining stable temperatures automatically.

Recommended Uses for Each Chilling Method

Sous vide chilling offers precise temperature control, making it ideal for delicate proteins and dishes requiring gradual cooling to maintain texture and flavor. This method is recommended for chefs aiming for consistency in fine dining and sous vide meal preps.

Controlled ice baths cool foods rapidly, preventing bacterial growth and are best suited for quickly chilling stocks, soups, and vegetables after cooking. Home cooks and commercial kitchens often use ice baths for their speed and effectiveness in food safety.

Related Important Terms

Rapid Cryo-Chill

Rapid Cryo-Chill using sous vide provides precise temperature control by immersing sealed food in ice water maintained at near 0degC, enabling faster and more consistent chilling compared to traditional controlled ice baths. The sous vide method minimizes temperature fluctuations and reduces bacterial growth risk, ensuring optimal food safety and quality during the rapid cooling process.

Hyperchill Transition

Sous vide chilling ensures precise temperature control with gradual cooling, preserving food quality during the Hyperchill Transition phase, while controlled ice baths often cause uneven temperature drops leading to texture and flavor loss. The Hyperchill Transition benefits from sous vide technology by minimizing thermal shock and microbial growth, resulting in safer and tastier chilled food.

Delta-T Gradient Drop

Sous vide chilling provides a precise and consistent Delta-T gradient drop, maintaining optimal temperature control for food safety and quality, whereas controlled ice baths often result in less uniform cooling with higher temperature fluctuations. This precise thermal regulation in sous vide minimizes bacterial growth and ensures even chilling throughout the product compared to the variable gradient seen in ice bath methods.

Flash Ice Bath Quench

Flash ice bath quenching rapidly chills sous vide-cooked foods by immersing vacuum-sealed bags in ice water, effectively halting the cooking process and preserving texture and flavor. Compared to controlled ice baths, flash quenching offers quicker temperature reduction, reducing bacterial growth risk and enhancing food safety.

SVIC (Sous Vide Ice Control)

Sous Vide Ice Control (SVIC) combines precise temperature regulation of sous vide with rapid chilling efficiency of a controlled ice bath, optimizing food safety and texture by swiftly lowering core temperatures. SVIC ensures consistent cooling below 5degC, minimizing bacterial growth while preserving moisture and flavor compared to traditional ice baths alone.

Thermal Shock Cooling

Sous vide cooling offers precise temperature control, minimizing thermal shock compared to traditional controlled ice baths, which can cause uneven cooling and textural damage. Thermal shock cooling through sous vide immersion ensures consistent, gentle temperature reduction, preserving food integrity and safety.

KinetiChill Finish

KinetiChill Finish offers precise temperature control and rapid chilling in sous vide cooking, outperforming traditional controlled ice baths by reducing bacterial growth and preserving food texture. Its automated circulation and cooling technology ensure consistent results, enhancing food safety and quality during the chilling process.

Post-Sous Rapid Set

Post-sous vide rapid chilling using a controlled ice bath ensures food safety by quickly reducing the temperature to inhibit bacterial growth, maintaining optimal texture and flavor. Unlike traditional chilling methods, the precise temperature control in a sous vide ice bath preserves the quality and extends shelf life more effectively.

Blast Ice Submersion

Blast ice submersion in sous vide chilling offers rapid temperature reduction by maximizing surface contact with ice-cold water, outperforming traditional controlled ice baths in efficiency. This method minimizes bacterial growth risks by quickly bringing cooked food through the danger zone, ensuring food safety and optimal texture retention.

Sous vide vs controlled ice bath for chilling Infographic

cookingdiff.com

cookingdiff.com