Sous vide cooking offers precise temperature control that ensures food is cooked evenly and safely by maintaining consistent heat levels, reducing the risk of harmful bacterial growth. Controlled water baths provide similar temperature stability but may lack the specialized circulation systems found in sous vide devices, which help maintain uniform heat distribution. Both methods enhance food safety compared to traditional cooking techniques, but sous vide machines often deliver superior consistency in temperature control crucial for pasteurization.

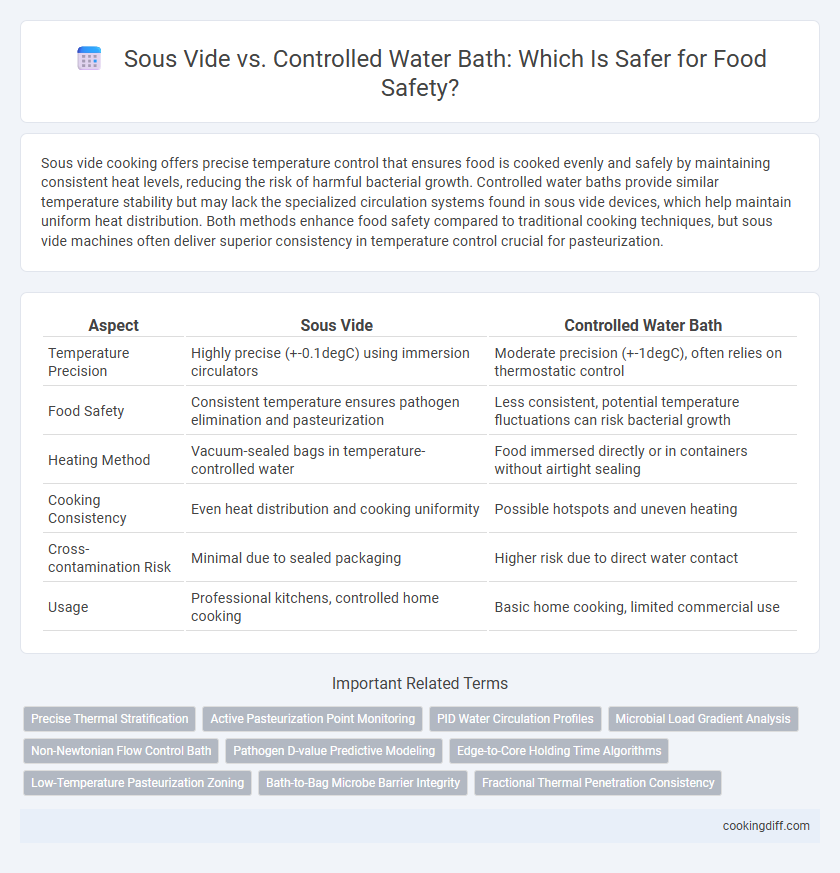

Table of Comparison

| Aspect | Sous Vide | Controlled Water Bath |

|---|---|---|

| Temperature Precision | Highly precise (+-0.1degC) using immersion circulators | Moderate precision (+-1degC), often relies on thermostatic control |

| Food Safety | Consistent temperature ensures pathogen elimination and pasteurization | Less consistent, potential temperature fluctuations can risk bacterial growth |

| Heating Method | Vacuum-sealed bags in temperature-controlled water | Food immersed directly or in containers without airtight sealing |

| Cooking Consistency | Even heat distribution and cooking uniformity | Possible hotspots and uneven heating |

| Cross-contamination Risk | Minimal due to sealed packaging | Higher risk due to direct water contact |

| Usage | Professional kitchens, controlled home cooking | Basic home cooking, limited commercial use |

Understanding Sous Vide and Controlled Water Bath Techniques

Sous vide cooking involves vacuum-sealing food and immersing it in a precisely temperature-controlled water bath, ensuring even heat distribution and consistent doneness. Controlled water baths maintain stable temperatures critical for killing harmful bacteria, reducing foodborne illness risks.

Both techniques rely on temperature accuracy to eliminate pathogens such as Salmonella and Listeria, with sous vide offering enhanced safety via vacuum sealing that limits bacterial growth. Understanding the thermal death points and holding times in these methods is essential for effective microbial control and food safety compliance.

How Each Method Maintains Precise Temperature Control

Sous vide and controlled water baths both achieve precise temperature control essential for food safety by using advanced heating elements and digital thermostats. Sous vide devices often provide more consistent temperature regulation due to their immersion circulators, which evenly distribute heat throughout the cooking water.

- Sous vide immersion circulators - Continuously circulate water to maintain uniform temperature around food, reducing hot spots and ensuring thorough cooking.

- Controlled water baths - Use static water heating with occasional manual stirring, requiring frequent monitoring to avoid temperature fluctuations.

- Digital temperature sensors - Integral to both methods, they enable precise control and adjustment to meet critical food safety standards by preventing bacteria growth.

The Science of Pasteurization: Sous Vide vs Controlled Water Bath

Sous vide cooking maintains precise temperature control essential for effective pasteurization, minimizing pathogen survival in food. Controlled water baths offer similar thermal environments but often lack the consistent temperature regulation needed for reliable microbial inactivation.

- Sous Vide Precision - Maintains stable temperatures within +-0.1degC, ensuring thorough and uniform pasteurization throughout the food.

- Controlled Water Bath Variability - Temperature fluctuations can compromise pathogen destruction, increasing the risk of unsafe food.

- Microbial Safety - Sous vide's strict heat control reduces bacterial load more reliably compared to most conventional controlled water baths.

Factors Influencing Food Safety in Low-Temperature Cooking

Sous vide cooking maintains precise temperature control, critical for eliminating harmful bacteria and ensuring food safety during low-temperature cooking. Controlled water baths provide consistent heat distribution, reducing the risk of bacterial growth compared to traditional methods. Factors such as temperature accuracy, cooking time, and water circulation significantly influence microbial safety in sous vide cooking.

Equipment Differences: Sous Vide Devices vs Water Baths

Sous vide devices are designed with precise temperature control and circulation to ensure consistent cooking, whereas traditional controlled water baths may lack such advanced features. This distinction is crucial for maintaining optimal food safety by preventing temperature fluctuations that can harbor bacteria growth.

- Sous Vide Precision - These devices maintain exact temperatures within 0.1degC to ensure thorough pasteurization.

- Water Bath Variability - Traditional water baths often have uneven heat distribution, risking undercooked spots.

- Circulation Mechanism - Sous vide machines actively circulate water, promoting uniform temperature around the food.

Reliable equipment with stable temperature control is essential for minimizing foodborne illness risks during low-temperature cooking.

Risks of Bacterial Growth and Prevention Strategies

Sous vide cooking requires precise temperature control to prevent bacterial growth, typically maintaining food at 55degC to 60degC for extended periods to ensure pathogen elimination. Controlled water baths provide consistent, even heating that minimizes cold spots where bacteria like Salmonella or Listeria could proliferate. Ensuring proper vacuum sealing and monitoring time-temperature parameters are crucial prevention strategies to maintain food safety during sous vide preparation.

Cooking Times and Their Impact on Pathogen Reduction

Cooking times in sous vide and controlled water baths are critical for effective pathogen reduction, as precise temperature control ensures consistent heat penetration. Extended cooking at lower temperatures in sous vide can achieve the same microbial kill rates as shorter, higher-temperature treatments in traditional water baths.

Studies show that maintaining food at 55degC to 60degC for 1 to 4 hours effectively reduces Salmonella and Listeria populations. Controlled water baths may require shorter times but higher temperatures, which can affect texture and nutrient retention compared to sous vide.

Food Handling Best Practices for Both Methods

Maintaining strict temperature controls and using sanitized equipment are essential in both sous vide and controlled water bath cooking to prevent bacterial growth. Proper vacuum sealing or airtight containment minimizes exposure to contaminants during cooking.

Regularly calibrating thermometers ensures accurate temperature readings, critical for achieving safe internal food temperatures. Avoid cross-contamination by handling raw and cooked foods separately and washing hands thoroughly. Following manufacturer guidelines for water circulation and cooking times further enhances food safety in both methods.

Common Mistakes That Compromise Food Safety

| Common Mistakes That Compromise Food Safety in Sous Vide vs Controlled Water Bath |

| Failure to maintain precise temperature control can allow harmful bacteria to survive, making consistent monitoring essential for both sous vide and controlled water baths. Using improper vacuum sealing techniques increases the risk of contamination by allowing air and microorganisms to enter the food package. Neglecting to cool cooked food rapidly before refrigeration promotes bacterial growth, undermining the safety advantage of sous vide cooking methods. |

Related Important Terms

Precise Thermal Stratification

Sous vide cooking utilizes precise thermal stratification within a controlled water bath to maintain consistent, accurate temperatures that eliminate pathogenic bacteria without overcooking. This targeted temperature control ensures enhanced food safety by preventing cold spots and uneven heat distribution common in traditional water baths.

Active Pasteurization Point Monitoring

Sous vide technology offers precise Active Pasteurization Point Monitoring by maintaining consistent temperature control critical for eliminating pathogens, whereas traditional controlled water baths may lack real-time adjustments, increasing the risk of temperature fluctuations and potential food safety hazards. The integration of sensors and automated temperature regulation in sous vide devices enhances pathogen destruction efficacy, ensuring safer pasteurization compared to conventional water bath methods.

PID Water Circulation Profiles

Sous vide cooking with PID water circulation profiles ensures precise temperature control within +-0.1degC, significantly reducing pathogen risks compared to traditional controlled water baths that may experience fluctuations exceeding +-1degC. Maintaining stable temperatures through PID regulation enhances pasteurization efficacy, promoting safer food preparation by effectively eliminating harmful bacteria such as Salmonella and Listeria.

Microbial Load Gradient Analysis

Sous vide cooking offers precise temperature control that minimizes microbial growth by maintaining food within a safe thermal zone, unlike traditional controlled water baths which may experience temperature fluctuations leading to uneven microbial load reduction. Microbial Load Gradient Analysis demonstrates that sous vide significantly reduces pathogens like Listeria monocytogenes and Salmonella spp. across the entire food matrix, ensuring enhanced food safety through consistent pasteurization.

Non-Newtonian Flow Control Bath

Sous vide cooking ensures precise temperature control critical for food safety, while a controlled water bath with Non-Newtonian flow properties enhances uniform heat distribution by dynamically adjusting fluid viscosity under stress. This advanced flow control minimizes temperature gradients, reducing bacterial growth risk and improving overall cooking consistency compared to standard sous vide immersion techniques.

Pathogen D-value Predictive Modeling

Sous vide cooking leverages precise temperature control to maintain food within safe microbial inactivation ranges, with pathogen D-value predictive modeling guiding optimal time-temperature combinations to reduce harmful bacteria. Controlled water baths enhance food safety by providing consistent heat distribution, enabling accurate application of these predictive models to effectively minimize pathogen survival rates.

Edge-to-Core Holding Time Algorithms

Sous vide cooking relies on precise edge-to-core holding time algorithms to ensure food reaches and maintains safe temperatures throughout the entire thickness, minimizing bacterial growth risks compared to generic controlled water baths. These algorithms optimize temperature uniformity and duration based on food density and thickness, providing a scientifically validated barrier against pathogenic contamination.

Low-Temperature Pasteurization Zoning

Sous vide cooking utilizes precise low-temperature pasteurization zoning to ensure even microbial inactivation, significantly reducing food safety risks compared to traditional controlled water baths. This method maintains consistent temperatures within narrow ranges, optimizing pathogen elimination without compromising food texture or quality.

Bath-to-Bag Microbe Barrier Integrity

Sous vide cooking ensures superior Bath-to-Bag Microbe Barrier Integrity by maintaining a precisely controlled water temperature that minimizes microbial contamination risks, unlike traditional controlled water baths which may experience temperature fluctuations compromising food safety. The vacuum-sealed bags used in sous vide act as a physical barrier, preventing cross-contamination and preserving pathogen-free conditions throughout the cooking process.

Sous vide vs controlled water bath for food safety. Infographic

cookingdiff.com

cookingdiff.com