Sous vide devices offer precise temperature control for cooking, while smart circulator networks enhance this by enabling remote device management and monitoring across multiple units. Integrating a smart circulator network allows chefs to optimize cooking processes, streamline operations, and maintain consistency in professional kitchens or large-scale culinary setups. This connectivity improves efficiency by providing real-time data and control, which traditional standalone sous vide machines lack.

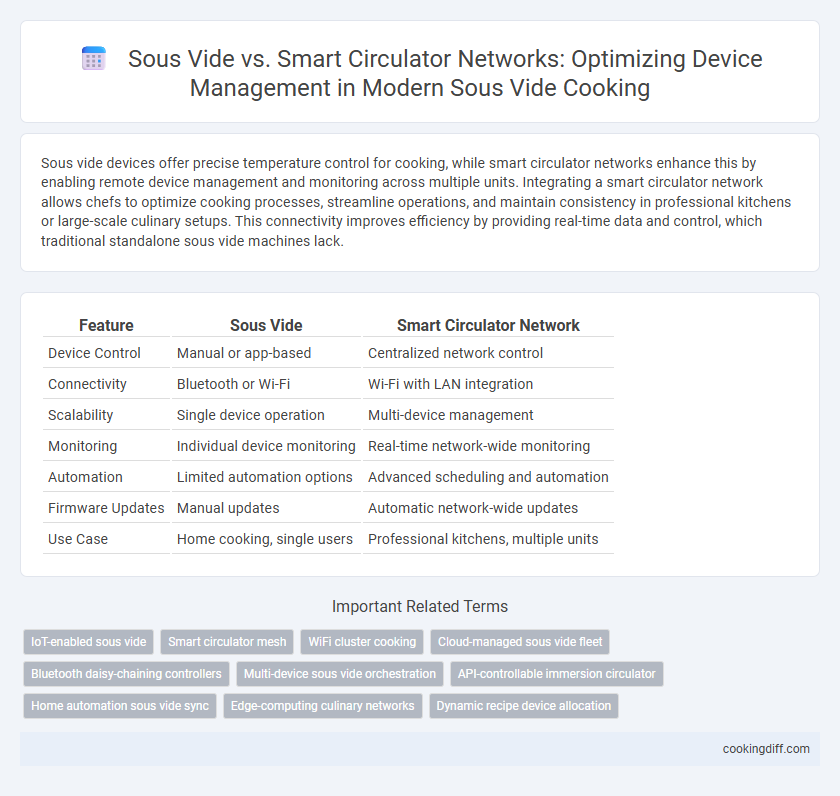

Table of Comparison

| Feature | Sous Vide | Smart Circulator Network |

|---|---|---|

| Device Control | Manual or app-based | Centralized network control |

| Connectivity | Bluetooth or Wi-Fi | Wi-Fi with LAN integration |

| Scalability | Single device operation | Multi-device management |

| Monitoring | Individual device monitoring | Real-time network-wide monitoring |

| Automation | Limited automation options | Advanced scheduling and automation |

| Firmware Updates | Manual updates | Automatic network-wide updates |

| Use Case | Home cooking, single users | Professional kitchens, multiple units |

Understanding Sous Vide: Traditional Precision Cooking

Sous vide is a traditional precision cooking technique that uses airtight vacuum-sealed bags immersed in temperature-controlled water baths to ensure consistent and even cooking. This method achieves exact temperatures, preserving texture and flavor while minimizing overcooking risks.

- Traditional Sous Vide Precision - Maintains water temperature within +-0.1degC for consistent cooking results.

- Manual Device Control - Typically operated through standalone immersion circulators without network connectivity.

- Focused Culinary Accuracy - Enables precise texture and doneness optimization, critical for gourmet and professional kitchens.

What is a Smart Circulator Network?

A Smart Circulator Network connects multiple sous vide devices, enabling centralized control and real-time monitoring through a single interface. This network uses Wi-Fi or Bluetooth technology to synchronize cooking temperatures and timing across all connected units.

By integrating sous vide devices into a smart circulator network, professional kitchens enhance operational efficiency and consistency in food preparation. The network supports remote device management, firmware updates, and data analytics to optimize cooking processes.

Key Differences: Manual Sous Vide vs Smart Networked Devices

Manual sous vide devices require users to set temperature and time individually, often lacking connectivity features. Smart circulator networks enable centralized control through apps, allowing remote monitoring and adjustments for multiple devices simultaneously.

Manual sous vide tools offer simplicity but limit scalability and automation in professional kitchens. Smart networked sous vide systems integrate IoT technology, enhancing precision and workflow efficiency by syncing multiple units. This connectivity supports real-time data tracking, improving overall device management and culinary consistency.

Device Management: Single Unit vs Networked Coordination

Sous vide devices typically operate as standalone units, limiting control to individual settings and manual intervention. In contrast, smart circulator networks enable centralized device management, allowing multiple units to sync settings and monitor cooking progress remotely.

- Standalone Operation - Traditional sous vide devices require manual adjustments for each unit, restricting efficiency in multi-device setups.

- Centralized Control - Smart circulator networks provide a unified interface for simultaneous command over multiple devices, enhancing precision and workflow.

- Real-Time Monitoring - Networked systems offer live status updates and notifications, improving oversight and reducing the risk of cooking errors.

Temperature Control: Precision and Consistency Compared

How does temperature control in sous vide compare to a smart circulator network for device management? Sous vide devices typically deliver precise and consistent temperature regulation through dedicated and isolated units, ensuring even cooking results. Smart circulator networks enhance this control by enabling real-time monitoring and adjustments across multiple devices, optimizing precision and consistency at scale.

Remote Monitoring and Control Capabilities

Sous vide devices integrated with smart circulator networks offer enhanced remote monitoring and control capabilities, allowing precise temperature adjustments and real-time status updates via mobile apps. These networks enable users to manage multiple sous vide machines simultaneously, improving efficiency in professional kitchens. Remote access reduces the risk of cooking errors by providing instant alerts and control from any location.

Integration with Smart Kitchen Ecosystems

Sous vide devices with smart circulator network integration enable seamless control within smart kitchen ecosystems. These systems offer enhanced connectivity and centralized device management for precision cooking.

- Interoperability - Smart circulator networks allow sous vide devices to communicate with other smart kitchen appliances through common protocols like Wi-Fi and Bluetooth.

- Remote Monitoring - Integration supports real-time monitoring and adjustments via mobile apps or voice assistants for improved user convenience.

- Automation - Connected sous vide devices can participate in automated cooking sequences coordinated by smart kitchen hubs.

Adopting sous vide technology with smart circulator network integration streamlines kitchen operations and elevates cooking precision.

Scaling Up: Multi-Device Operations and Automation

| Sous vide precision cooking | Single-device control, manual settings |

| Smart circulator network | Enables multi-device management, centralized automation for large-scale culinary operations |

| Scaling Up | Smart circulator systems support simultaneous cooking workflows, remote monitoring, and automated adjustments, optimizing kitchen efficiency and consistency |

Energy Efficiency and Resource Management

Sous vide devices equipped with smart circulator networks significantly enhance energy efficiency by optimizing water temperature and circulation based on real-time data. These systems enable precise resource management, reducing energy waste and minimizing water usage compared to traditional standalone sous vide devices. Integrating smart circulators within a network facilitates remote monitoring and automated adjustments, leading to improved sustainability in professional and home kitchens.

Related Important Terms

IoT-enabled sous vide

IoT-enabled sous vide devices leverage smart circulator networks to enable real-time remote monitoring, precise temperature control, and streamlined recipe sharing, enhancing culinary consistency and convenience. These interconnected systems utilize cloud-based platforms for device management, firmware updates, and data analytics, optimizing user experience and operational efficiency in smart kitchens.

Smart circulator mesh

Smart circulator mesh technology enables seamless device management by creating a robust, interconnected network of sous vide cookers that communicate in real-time to optimize cooking precision and energy efficiency. Unlike traditional sous vide systems, this mesh network allows for centralized control, automatic updates, and synchronized cooking processes across multiple units, significantly enhancing scalability and user convenience in professional and home kitchens.

WiFi cluster cooking

Sous vide devices with WiFi cluster cooking leverage smart circulator networks to synchronize multiple units, enabling precise temperature control and consistent cooking results across large batches. This networked approach streamlines device management through centralized app interfaces, improving efficiency and scalability in professional kitchens.

Cloud-managed sous vide fleet

Cloud-managed sous vide fleets enable centralized control and real-time monitoring of multiple devices through a smart circulator network, optimizing precision cooking and operational efficiency. This integration allows seamless firmware updates, usage analytics, and remote diagnostics, enhancing scalability for commercial kitchens and culinary institutions.

Bluetooth daisy-chaining controllers

Bluetooth daisy-chaining controllers in sous vide devices enable seamless networked device management by linking multiple smart circulators, enhancing synchronization and remote control capabilities. This method outperforms traditional single-device setups by facilitating expanded cooking capacity and coordinated temperature precision across connected units.

Multi-device sous vide orchestration

Multi-device sous vide orchestration using a smart circulator network enables precise temperature control and synchronized cooking across multiple containers, enhancing scalability and consistency in professional kitchens. Centralized device management streamlines workflow by allowing real-time monitoring, remote adjustments, and automated recipe execution for superior culinary efficiency.

API-controllable immersion circulator

API-controllable immersion circulators enable seamless integration into smart circulator networks, allowing centralized device management and precise temperature control for sous vide cooking. These networks enhance operational efficiency by providing real-time monitoring, remote access, and automated scheduling, optimizing culinary consistency and scalability in professional kitchens.

Home automation sous vide sync

Sous vide devices with smart circulator network capabilities enable seamless integration into home automation systems, allowing users to remotely monitor and control cooking parameters through synchronized apps. This connectivity enhances precision cooking by syncing multiple sous vide units for coordinated temperature management across different dishes or meal courses.

Edge-computing culinary networks

Sous vide systems integrated with smart circulator networks leverage edge computing to optimize device management by enabling real-time temperature control, automated cooking profiles, and remote monitoring across multiple culinary stations. This decentralized approach reduces latency and enhances precision, making it ideal for professional kitchens requiring seamless coordination and scalability in sous vide cooking operations.

Sous vide vs Smart circulator network for device management. Infographic

cookingdiff.com

cookingdiff.com