A polycarbonate container offers better heat retention and consistent temperature control compared to a standard pot, making it ideal for sous vide cooking. Its transparent design allows easy monitoring of water levels without losing heat, while the standard pot may require frequent water topping and has less insulation. For precision and efficiency in sous vide pet meal preparation, a polycarbonate container outperforms a traditional pot.

Table of Comparison

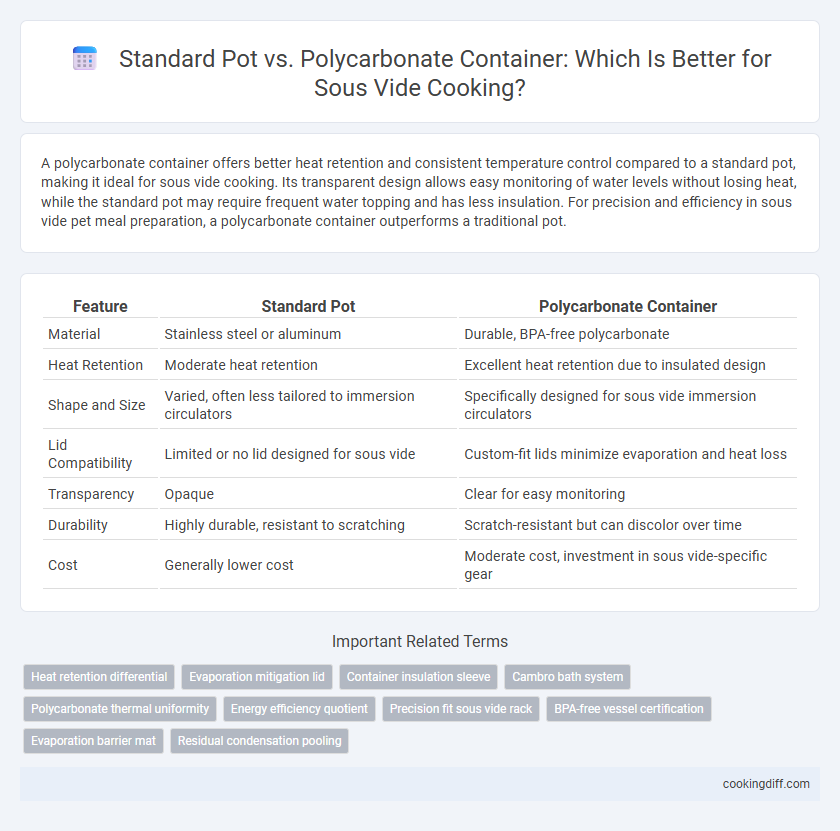

| Feature | Standard Pot | Polycarbonate Container |

|---|---|---|

| Material | Stainless steel or aluminum | Durable, BPA-free polycarbonate |

| Heat Retention | Moderate heat retention | Excellent heat retention due to insulated design |

| Shape and Size | Varied, often less tailored to immersion circulators | Specifically designed for sous vide immersion circulators |

| Lid Compatibility | Limited or no lid designed for sous vide | Custom-fit lids minimize evaporation and heat loss |

| Transparency | Opaque | Clear for easy monitoring |

| Durability | Highly durable, resistant to scratching | Scratch-resistant but can discolor over time |

| Cost | Generally lower cost | Moderate cost, investment in sous vide-specific gear |

Introduction: Choosing the Right Sous Vide Container

Which is better for sous vide cooking: a standard pot or a polycarbonate container? Standard pots provide versatility for everyday cooking but may lack consistent heat distribution and lid compatibility crucial for sous vide precision. Polycarbonate containers are designed for sous vide, offering better insulation, uniform water circulation, and often come with custom lids to minimize water evaporation.

Material Differences: Stainless Steel Pot vs Polycarbonate Container

Stainless steel pots offer superior heat retention and durability, making them ideal for precise temperature control in sous vide cooking. Polycarbonate containers are lightweight and transparent, allowing easy monitoring of water levels and cooking progress. While stainless steel resists staining and corrosion, polycarbonate containers provide greater flexibility with immersion circulators attached directly to the side.

Heat Retention and Temperature Stability

Standard pots typically offer moderate heat retention, but their metal walls can lead to quicker temperature fluctuations during sous vide cooking. Polycarbonate containers, with their insulated structure, maintain more consistent temperatures, enhancing cooking precision.

Polycarbonate containers reduce heat loss effectively due to their thicker, non-metallic sides, ensuring longer temperature stability essential for sous vide applications. Standard pots often require more frequent monitoring and adjustments to maintain target temperatures. Using polycarbonate containers ultimately supports even cooking by minimizing heat variations commonly caused by metal pot conduction.

Water Circulation Efficiency

Sous vide cooking requires consistent water circulation to maintain precise temperature control. Polycarbonate containers offer better water flow dynamics than standard pots, enhancing temperature uniformity.

- Polycarbonate containers promote superior water circulation - Their smooth, rectangular design enables efficient movement of heated water around the food.

- Standard pots often result in uneven heat distribution - Rounded edges and varied shapes can create hot and cold spots, impacting cooking accuracy.

- Polycarbonate containers accommodate immersion circulators effectively - Their size and structure ensure optimal placement for consistent water flow across the container.

Lid and Cover Options

Standard pots for sous vide often lack dedicated lids, causing heat and moisture loss that can affect cooking precision and efficiency. Polycarbonate containers offer custom-fit lids designed to minimize evaporation and maintain consistent water temperature, enhancing cooking accuracy.

Polycarbonate lids typically feature cutouts or seals to accommodate immersion circulators and lifting mechanisms without compromising the sealed environment. In contrast, standard pots usually require improvised covers like plastic wrap or aluminum foil, which may not provide an airtight seal essential for optimal sous vide results.

Size and Capacity Considerations

Standard pots for sous vide typically offer limited capacity, ranging from 6 to 12 quarts, suitable for smaller meals and household use. Polycarbonate containers provide larger volume options, often exceeding 20 quarts, accommodating bulk cooking or multiple servings efficiently. The choice between these depends on the size of the sous vide setup and meal preparation requirements.

Safety and Food-Grade Concerns

Standard pots used for sous vide cooking are typically made from stainless steel or aluminum, offering excellent heat retention and food safety due to their non-reactive surfaces. Polycarbonate containers, while lightweight and highly transparent, may raise concerns over chemical leaching, especially when exposed to high temperatures for extended periods.

Food-grade polycarbonate containers must comply with FDA regulations to ensure they do not release harmful substances during cooking. Choosing materials certified for food contact and designed for sous vide use enhances safety and preserves the quality of vacuum-sealed ingredients.

Ease of Cleaning and Maintenance

Standard pots are generally easier to clean due to their smooth stainless steel surfaces which resist staining and odor retention. Polycarbonate containers require more careful cleaning to avoid scratches that can harbor bacteria and affect clarity over time.

- Standard pots resist staining - Stainless steel surfaces provide a non-porous texture that simplifies cleaning and maintenance.

- Polycarbonate containers scratch easily - Scratches on polycarbonate create areas for bacteria buildup and complicate cleaning routines.

- Maintenance frequency differs - Standard pots need less frequent deep cleaning compared to polycarbonate containers used in sous vide cooking.

Storage and Space Requirements

| Standard Pot | Requires less vertical storage space due to compact size, but can be bulky and heavy when filled with water. |

| Polycarbonate Container | Offers stackable design for efficient storage and lightweight construction, saving overall kitchen space when not in use. |

Related Important Terms

Heat retention differential

Polycarbonate containers provide superior heat retention compared to standard pots due to their insulated construction and airtight lids, maintaining water temperature more consistently during sous vide cooking. Standard pots lose heat faster through metal surfaces and open tops, requiring more frequent temperature adjustments and energy use.

Evaporation mitigation lid

Polycarbonate containers with specialized lids significantly reduce water evaporation during sous vide cooking compared to standard pots, maintaining consistent water levels and temperature stability. These lids create a tight seal, minimizing steam loss and enhancing cooking efficiency for longer cook times.

Container insulation sleeve

Polycarbonate containers with insulation sleeves offer superior temperature stability for sous vide cooking compared to standard pots, minimizing heat loss and reducing energy consumption. Insulation sleeves around polycarbonate containers enhance thermal retention, ensuring precise water temperature control critical for consistent sous vide results.

Cambro bath system

The Cambro polycarbonate container offers superior heat retention and durability compared to a standard pot, ensuring consistent temperature control essential for precise sous vide cooking. Its stackable design and multiple capacity options make the Cambro bath system a versatile and efficient choice for both home cooks and professional kitchens.

Polycarbonate thermal uniformity

Polycarbonate containers for sous vide cooking offer superior thermal uniformity compared to standard pots, ensuring consistent water temperature throughout the cooking process. Their rigid construction minimizes heat loss and improves circulation efficiency, resulting in more precise and reliable sous vide results.

Energy efficiency quotient

Polycarbonate containers for sous vide cooking maintain water temperature more consistently, reducing energy consumption compared to standard pots. Their insulated design minimizes heat loss, leading to a higher energy efficiency quotient during extended cooking sessions.

Precision fit sous vide rack

A precision fit sous vide rack ensures optimal water circulation and stability whether using a standard pot or a polycarbonate container, preventing food from floating and maintaining consistent temperature zones. Polycarbonate containers paired with precision racks offer enhanced heat retention and visibility, while standard pots are more accessible but may require careful rack selection to maximize efficiency.

BPA-free vessel certification

Polycarbonate containers for sous vide cooking often come with BPA-free certification, ensuring food safety and preventing harmful chemical leaching at precise temperature control. Standard pots typically lack such certifications, making BPA-free polycarbonate vessels a safer choice for prolonged sous vide immersion.

Evaporation barrier mat

Using a polycarbonate container with an evaporation barrier mat significantly reduces water loss during sous vide cooking compared to a standard pot, maintaining consistent temperature and cooking precision. The barrier mat minimizes evaporation, allowing for longer cooking times and improved energy efficiency, essential for sous vide techniques.

Standard pot vs polycarbonate container for sous vide. Infographic

cookingdiff.com

cookingdiff.com