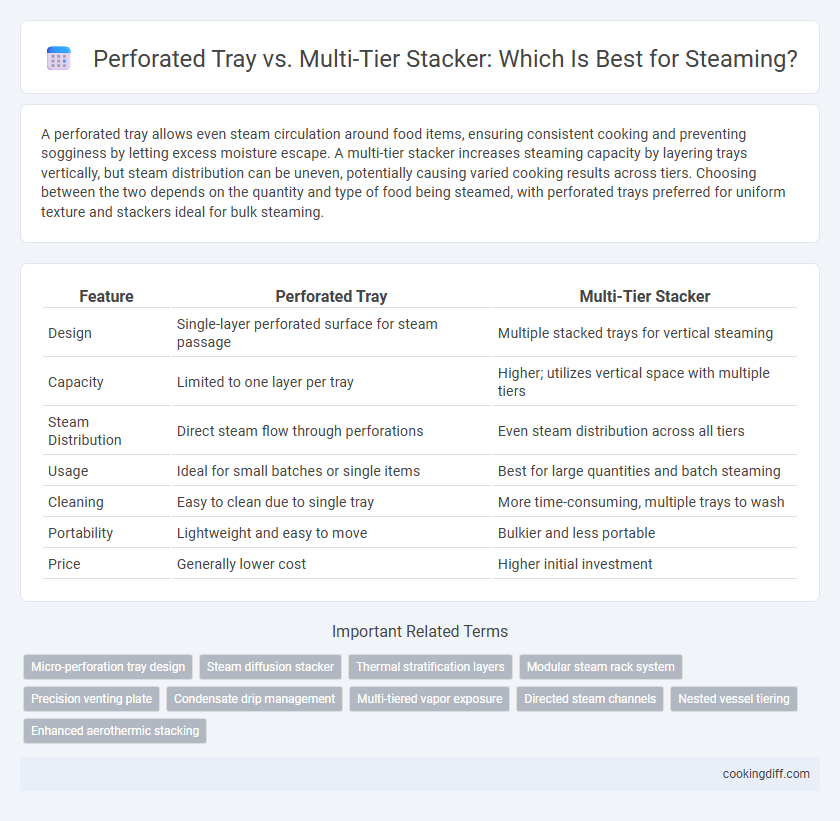

A perforated tray allows even steam circulation around food items, ensuring consistent cooking and preventing sogginess by letting excess moisture escape. A multi-tier stacker increases steaming capacity by layering trays vertically, but steam distribution can be uneven, potentially causing varied cooking results across tiers. Choosing between the two depends on the quantity and type of food being steamed, with perforated trays preferred for uniform texture and stackers ideal for bulk steaming.

Table of Comparison

| Feature | Perforated Tray | Multi-Tier Stacker |

|---|---|---|

| Design | Single-layer perforated surface for steam passage | Multiple stacked trays for vertical steaming |

| Capacity | Limited to one layer per tray | Higher; utilizes vertical space with multiple tiers |

| Steam Distribution | Direct steam flow through perforations | Even steam distribution across all tiers |

| Usage | Ideal for small batches or single items | Best for large quantities and batch steaming |

| Cleaning | Easy to clean due to single tray | More time-consuming, multiple trays to wash |

| Portability | Lightweight and easy to move | Bulkier and less portable |

| Price | Generally lower cost | Higher initial investment |

Introduction to Steaming: Perforated Tray vs Multi-Tier Stacker

Perforated trays and multi-tier stackers are essential tools in steaming, each offering unique benefits for efficient cooking. Perforated trays allow steam to circulate evenly around individual food items, enhancing texture and flavor retention. Multi-tier stackers maximize cooking capacity by enabling simultaneous steaming of multiple layers, ideal for large batches or varied dishes.

How Perforated Trays Enhance Steam Circulation

| Perforated Trays | Featuring evenly distributed holes, perforated trays facilitate superior steam circulation, allowing steam to envelop food evenly and ensuring consistent cooking without hotspots. |

| Multi-Tier Stacker | While multi-tier stackers increase capacity by layering trays vertically, steam circulation can be less efficient on lower tiers, potentially causing uneven cooking compared to perforated trays. |

| Benefit of Perforated Trays | The enhanced airflow through perforated trays promotes uniform heat distribution, improving texture and flavor retention in steamed foods. |

Multi-Tier Stackers: Maximizing Steaming Capacity

Multi-tier stackers significantly increase steaming capacity by allowing multiple layers of food to be steamed simultaneously, optimizing kitchen efficiency. Each tier enables uniform steam distribution, ensuring consistent cooking results across all levels.

Compared to perforated trays, multi-tier stackers maximize vertical space usage, making them ideal for commercial kitchens with limited countertop area. Their design supports diverse food types and portion sizes, enhancing versatility in steaming applications.

Material Considerations: Selecting the Right Steaming Tool

Choosing between a perforated tray and a multi-tier stacker for steaming depends heavily on the material's heat conductivity and durability. Stainless steel trays offer superior corrosion resistance, while aluminum stackers provide lightweight heat distribution.

- Stainless steel perforated trays - Known for durability and resistance to rust, ideal for long-term use with acidic foods.

- Aluminum multi-tier stackers - Lightweight and excellent in heat conduction, making them efficient for quick steaming.

- Silicone inserts - Heat-resistant and non-stick, suitable for delicate foods but less durable than metal options.

Even Heat Distribution: Which Method Performs Better?

Perforated trays allow steam to circulate more freely around food items, promoting even heat distribution and consistent cooking results. Multi-tier stackers, while space-efficient, can create uneven heat zones as steam pressure and temperature vary between tiers. For optimal steaming performance, perforated trays generally provide better and more uniform heat coverage compared to multi-tier stackers.

Cleaning and Maintenance: Perforated Tray or Multi-Tier Stacker?

Perforated trays offer straightforward cleaning due to their simple structure, allowing easy access to all surfaces. In contrast, multi-tier stackers require disassembly, which can be time-consuming but ensures thorough maintenance of each tier.

Multi-tier stackers may trap food particles between tiers, necessitating careful cleaning to prevent buildup and ensure hygiene. Their complex design demands regular inspection to avoid issues like mold or residue buildup in hard-to-reach areas. Perforated trays, with fewer nooks, reduce the risk of contamination and streamline routine maintenance.

Versatility in the Kitchen: Adapting to Different Dishes

Perforated trays offer targeted steam exposure ideal for delicate items like vegetables and fish, while multi-tier stackers maximize cooking volume for large meals or multiple dishes simultaneously. Choosing between them depends on the desired efficiency and food type adaptability in your kitchen.

- Perforated Tray Precision - Allows steam to circulate evenly around individual foods, preserving texture and flavor in delicate ingredients.

- Multi-tier Stacker Capacity - Enables steaming of several different foods at once, saving time and energy when preparing complex meals.

- Versatile Cooking Options - Both tools can adapt to varied recipes by adjusting tiers or tray arrangement to fit specific steaming needs.

Space Efficiency: Storage and Kitchen Footprint

Which option offers better space efficiency for steaming: a perforated tray or a multi-tier stacker? Perforated trays are compact and easy to store, making them ideal for kitchens with limited storage. Multi-tier stackers maximize vertical space during cooking but require more room when stored due to their height and assembly complexity.

Cost Comparison: Investment and Long-Term Value

Perforated trays typically require a lower initial investment compared to multi-tier stackers, making them more cost-effective for small-scale operations. They offer straightforward maintenance and replacement, contributing to reduced upfront expenses.

Multi-tier stackers, while more expensive initially, deliver higher capacity and improved efficiency, leading to better long-term value in large-scale steaming processes. Their durable construction and optimized space utilization decrease operational costs over time.

Related Important Terms

Micro-perforation tray design

Micro-perforation tray designs optimize steam circulation by enabling uniform heat distribution and moisture retention compared to traditional multi-tier stackers, which can cause uneven cooking and water pooling. This design improves cooking efficiency and food texture by providing consistent steam penetration through tiny perforations that prevent dripping and promote faster, even steaming.

Steam diffusion stacker

Steam diffusion stackers ensure even steam distribution by allowing vapor to circulate freely through perforated trays, enhancing cooking uniformity and reducing energy consumption. Multi-tier stackers maximize capacity but may cause uneven steam flow, making perforated tray designs superior for consistent heat transfer and better food quality.

Thermal stratification layers

Perforated trays promote more uniform heat distribution by allowing steam to circulate freely, minimizing thermal stratification layers within the steaming chamber. Multi-tier stackers can create distinct thermal layers due to restricted steam flow between tiers, potentially leading to uneven cooking and temperature gradients.

Modular steam rack system

A modular steam rack system featuring perforated trays ensures even steam distribution and optimal moisture retention by allowing steam to circulate freely around food items, enhancing cooking efficiency and texture. Multi-tier stackers increase capacity but may hinder uniform steam exposure, making perforated trays superior for consistent steaming results in commercial kitchens.

Precision venting plate

Perforated trays offer uniform steam distribution through precision venting plates that ensure consistent heat and moisture flow, optimizing cooking efficiency and food texture. Multi-tier stackers, while maximizing capacity, rely on the cumulative steam pressure, which can lead to uneven cooking compared to the targeted venting precision of perforated trays.

Condensate drip management

Perforated trays facilitate better condensate drip management by allowing steam to pass through evenly and excess water to drain directly, reducing sogginess in food. Multi-tier stackers tend to trap condensate between layers, increasing the risk of moisture buildup and uneven steaming.

Multi-tiered vapor exposure

Multi-tier stackers optimize steaming by allowing uniform vapor exposure across all layers, enhancing cooking efficiency and consistency. Perforated trays provide limited surface area for steam circulation, making multi-tier systems superior for evenly cooked results in large batch steaming.

Directed steam channels

Perforated trays feature individually spaced holes allowing steam to rise directly to each food item, enhancing even cooking through focused steam channels. Multi-tier stackers distribute steam vertically between layers, but may cause uneven heat flow due to limited directed steam channels, affecting consistent steaming results.

Nested vessel tiering

Perforated trays offer uniform steam circulation through evenly spaced holes, enhancing heat distribution in nested vessel tiering systems, while multi-tier stackers maximize vertical space by allowing multiple layers of nested vessels but may limit individual vessel exposure to direct steam. Optimizing nested vessel tiering involves balancing the superior steam penetration of perforated trays against the space efficiency of multi-tier stackers to achieve consistent cooking results.

Perforated tray vs multi-tier stacker for steaming. Infographic

cookingdiff.com

cookingdiff.com