Steaming in baking preserves moisture and enhances texture by injecting steam directly into the oven, which helps create a crisp crust and tender crumb. Combi-oven steam injection combines steam with dry heat, allowing precise control over humidity and temperature for consistent baking results. This method improves oven spring and crust development, offering versatility for a wide range of bakery products.

Table of Comparison

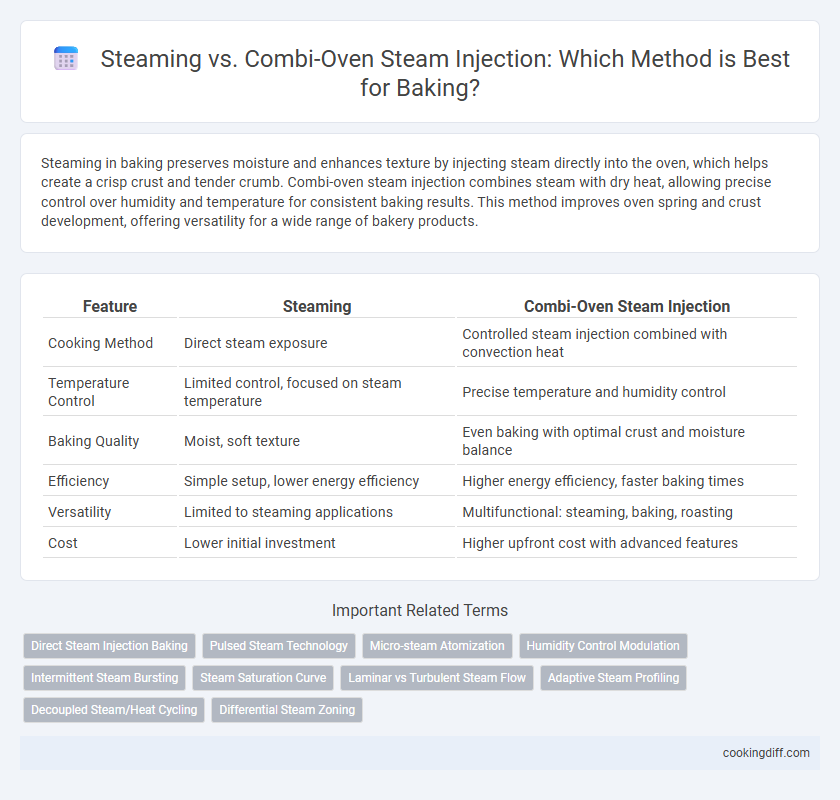

| Feature | Steaming | Combi-Oven Steam Injection |

|---|---|---|

| Cooking Method | Direct steam exposure | Controlled steam injection combined with convection heat |

| Temperature Control | Limited control, focused on steam temperature | Precise temperature and humidity control |

| Baking Quality | Moist, soft texture | Even baking with optimal crust and moisture balance |

| Efficiency | Simple setup, lower energy efficiency | Higher energy efficiency, faster baking times |

| Versatility | Limited to steaming applications | Multifunctional: steaming, baking, roasting |

| Cost | Lower initial investment | Higher upfront cost with advanced features |

Introduction to Baking: Steaming vs Combi-Oven Steam Injection

Steaming and combi-oven steam injection are two essential methods used in baking to control moisture and texture. Each technique offers unique benefits that influence the final product quality and baking efficiency.

- Steaming - Introduces moisture directly into the baking chamber, creating a humid environment that improves crust formation and crumb softness.

- Combi-oven Steam Injection - Combines steam with convection heat, allowing precise control over humidity and temperature to optimize baking performance.

- Comparison - Steaming provides simplicity and cost-effectiveness, while combi-oven steam injection enhances consistency and baking versatility in professional kitchens.

Understanding Traditional Steaming Techniques in Baking

| Traditional steaming techniques in baking involve using direct steam to create a moist environment that promotes dough expansion and crust development. This method enhances oven spring and results in a shiny, crisp crust by gelatinizing the starches on the dough's surface. Unlike combi-oven steam injection, traditional steaming maintains consistent humidity without aggressive heat cycling, preserving the bakery's artisanal quality. |

What is Combi-Oven Steam Injection?

Combi-oven steam injection is a baking technique where steam is introduced directly into the oven chamber to regulate humidity and enhance baking results. This method allows precise control over temperature and moisture, improving crust texture and crumb development in bread and pastries. Compared to traditional steaming, combi-oven steam injection offers consistent steam distribution and energy efficiency, making it ideal for commercial baking environments.

Equipment Comparison: Steamer vs Combi-Oven

Steaming offers precise moisture control ideal for delicate baking, while combi-oven steam injection combines steam and convection heat for versatile baking performance. Each equipment type provides distinct benefits based on baking requirements and kitchen setup.

- Moisture Control - Steamers deliver consistent humidity levels essential for maintaining dough elasticity and crust texture.

- Temperature Versatility - Combi-ovens integrate steam injection with adjustable dry heat for varied baking profiles from bread to pastries.

- Energy Efficiency - Combi-ovens typically consume more energy but reduce cooking time through multifunctional capabilities.

Effects on Crust and Crumb Texture

Steaming during baking enhances crust crispness by injecting moisture that delays crust formation, resulting in a glossy, chewy exterior. Combi-oven steam injection provides precise control over humidity, producing consistent crumb texture with an open, airy structure and uniform crumb softness. This method reduces baking time while maintaining optimal crust thickness and an ideal crumb moistness for artisan bread quality.

Impact on Flavor and Aroma Development

How does steaming compare to combi-oven steam injection in terms of flavor and aroma development during baking? Steaming provides a gentle moisture environment that enhances the crust's caramelization, resulting in a richer, more complex flavor profile. Combi-oven steam injection offers precise control over humidity levels, promoting uniform aroma development and consistent texture throughout the baked goods.

Moisture Control: Pros and Cons of Each Method

Steaming provides consistent moisture levels ideal for delicate bakery products, ensuring even texture and crust formation. However, it may lack precise control over humidity, potentially leading to soggier results if not carefully monitored.

Combi-oven steam injection allows accurate humidity regulation during baking, optimizing moisture retention and crust quality for diverse product types. This method requires advanced equipment and programming but offers superior control to achieve tailored baking outcomes.

Energy Efficiency and Operational Considerations

Steaming utilizes direct injection of steam into the oven cavity, resulting in rapid heat transfer that reduces baking time and energy consumption. Combi-oven steam injection combines steam and convection heat, offering precise humidity control which enhances product quality but may consume more energy due to its complex systems.

Energy efficiency in steaming is generally higher for simple baking tasks because it requires less preparation and maintains consistent moisture. Combi-oven steam injection systems demand higher initial investment and maintenance but provide operational flexibility that can reduce waste and optimize baking cycles. Understanding the specific baking requirements and production volume is essential to selecting the most energy-efficient and operationally sustainable method.

Versatility and Limitations in Home and Commercial Baking

Steaming in traditional ovens provides consistent moisture ideal for artisan bread, enhancing crust texture but lacks precise control over humidity levels compared to combi-oven steam injection. Combi-oven technology offers versatile steam settings and temperature control, enabling a wider range of baked goods and improved repeatability in commercial baking environments.

Home bakers often face limitations with oven steaming due to less advanced moisture regulation, making combi-ovens more suitable for professional kitchens requiring high-volume and diverse baking processes. Despite higher costs and complexity, combi-ovens deliver uniform steam distribution and operational efficiency, crucial for commercial bakery productivity and product consistency.

Related Important Terms

Direct Steam Injection Baking

Direct steam injection baking delivers precise humidity control by injecting steam directly into the oven chamber, enhancing crust development and crumb texture in baked goods. This method outperforms combi-oven steam injection by reducing bake times and energy consumption while maintaining consistent moisture levels for superior product quality.

Pulsed Steam Technology

Pulsed Steam Technology in steaming offers precise moisture control and rapid temperature recovery, enhancing crust development and crumb texture compared to traditional combi-oven steam injection. This technology delivers bursts of steam that improve heat transfer efficiency and product consistency, making it ideal for artisan baking and high-volume production environments.

Micro-steam Atomization

Micro-steam atomization in baking delivers ultra-fine steam particles that enhance crust formation and moisture retention more effectively than conventional combi-oven steam injection. This precise steam distribution improves oven spring and texture, optimizing bread quality with lower energy consumption and reduced baking times.

Humidity Control Modulation

Steaming provides precise humidity control by introducing consistent moisture levels during baking, enhancing crust texture and crumb development, while combi-oven steam injection offers dynamic humidity modulation through programmable settings that adapt to different baking phases for optimized moisture retention and product quality. Effective humidity control modulation in both methods ensures uniform heat distribution and prevents crust cracking, crucial for artisanal bread and delicate pastries.

Intermittent Steam Bursting

Intermittent steam bursting delivers controlled bursts of steam at specific intervals, enhancing crust development and oven spring in baking compared to the continuous steam injection of combi-ovens. This method optimizes moisture retention and crispiness, producing artisan-quality bread with a superior texture and volume.

Steam Saturation Curve

Steaming in traditional ovens offers inconsistent steam saturation levels, which can affect crust development and crumb texture during baking. Combi-oven steam injection precisely controls the steam saturation curve, ensuring optimal moisture retention and superior baking results with uniform crustiness and enhanced volume.

Laminar vs Turbulent Steam Flow

Laminar steam flow in traditional steaming provides consistent, gentle heat ideal for delicate baked goods, while turbulent steam flow in combi-oven steam injection enhances heat transfer and moisture distribution, resulting in faster baking and improved crust formation. The controlled turbulence in combi-ovens ensures even steam penetration and uniform baking outcomes compared to the steady but slower laminar flow in conventional steaming methods.

Adaptive Steam Profiling

Adaptive Steam Profiling in combi-oven steam injection offers precise control over humidity levels during baking, enhancing crust texture and crumb structure compared to traditional steaming methods. This technology dynamically adjusts steam intensity to optimize heat transfer, improving product consistency and reducing baking times.

Decoupled Steam/Heat Cycling

Decoupled steam and heat cycling in baking allows precise control over humidity and temperature, enhancing crust formation and crumb texture compared to traditional combi-oven steam injection which integrates steam with heat simultaneously. This method optimizes moisture retention and promotes even baking, resulting in superior product quality and consistency.

Steaming vs Combi-oven steam injection for baking. Infographic

cookingdiff.com

cookingdiff.com