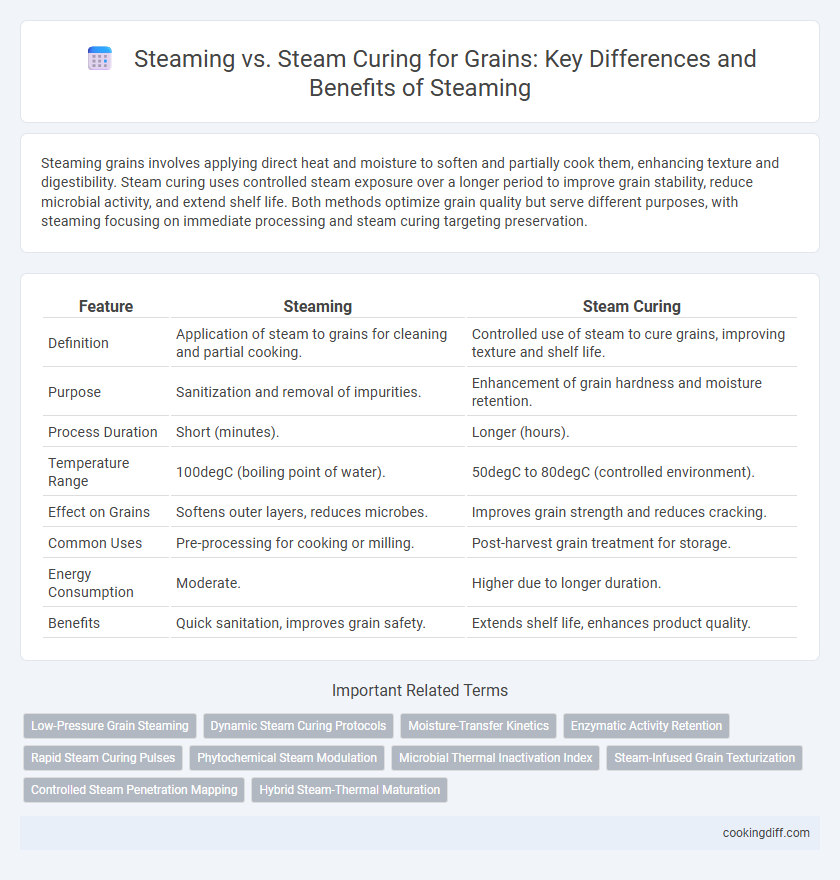

Steaming grains involves applying direct heat and moisture to soften and partially cook them, enhancing texture and digestibility. Steam curing uses controlled steam exposure over a longer period to improve grain stability, reduce microbial activity, and extend shelf life. Both methods optimize grain quality but serve different purposes, with steaming focusing on immediate processing and steam curing targeting preservation.

Table of Comparison

| Feature | Steaming | Steam Curing |

|---|---|---|

| Definition | Application of steam to grains for cleaning and partial cooking. | Controlled use of steam to cure grains, improving texture and shelf life. |

| Purpose | Sanitization and removal of impurities. | Enhancement of grain hardness and moisture retention. |

| Process Duration | Short (minutes). | Longer (hours). |

| Temperature Range | 100degC (boiling point of water). | 50degC to 80degC (controlled environment). |

| Effect on Grains | Softens outer layers, reduces microbes. | Improves grain strength and reduces cracking. |

| Common Uses | Pre-processing for cooking or milling. | Post-harvest grain treatment for storage. |

| Energy Consumption | Moderate. | Higher due to longer duration. |

| Benefits | Quick sanitation, improves grain safety. | Extends shelf life, enhances product quality. |

Introduction to Steaming and Steam Curing

Steaming involves applying moist heat at high temperatures to grains, enhancing their texture and flavor. Steam curing uses controlled steam exposure to improve grain preservation and reduce microbial growth. Both processes optimize grain quality but serve different purposes in food processing.

Understanding the Basics: Steaming vs. Steam Curing

Steaming involves applying moist heat to grains to soften them and initiate the cooking process, enhancing texture and digestibility. Steam curing, however, uses controlled steam exposure combined with curing agents to preserve grains and improve shelf life.

The key difference lies in steaming mainly preparing grains for consumption, while steam curing extends preservation and flavor development. Understanding these basics helps optimize grain processing techniques based on quality and storage goals.

Equipment Required for Each Method

Steaming grains requires a basic setup including a steam generator or boiler, steam pipes, and an enclosed chamber to ensure even heat distribution. Steam curing, on the other hand, involves more specialized equipment such as pressurized steam chambers and temperature control systems to optimize grain moisture and texture. Both methods rely heavily on the efficiency of the steam source, but steam curing demands higher precision and more advanced control technology to achieve consistent results.

Process Differences: How Steaming and Steam Curing Work

Steaming involves exposing grains to direct steam vapor for a short duration to soften the outer layers, enhancing texture and cooking properties. Steam curing, however, subjects grains to prolonged steam exposure combined with controlled temperature and humidity to induce chemical changes that improve preservation and flavor development.

During steaming, heat penetrates quickly, causing starch gelatinization without altering the grain's internal structure significantly. In contrast, steam curing triggers enzymatic and microbial activity modifications, resulting in improved shelf life and nutritional qualities through a gradual, controlled process.

Impact on Grain Texture and Nutritional Value

Steaming grains uses high-temperature steam to cook them quickly, preserving a firm texture and retaining most nutrients. Steam curing involves prolonged exposure to steam and heat, often altering grain texture and potentially reducing some heat-sensitive nutrients.

- Steaming preserves grain texture - It results in a tender yet firm grain consistency ideal for cooking.

- Steam curing alters texture - Extended steam reduces firmness and can make grains softer or mushy.

- Nutritional retention differs - Steaming maintains more vitamins and minerals compared to steam curing.

Choosing between steaming and steam curing depends on desired grain texture and nutritional goals.

Time and Temperature Considerations

Steaming grains typically involves shorter exposure times at temperatures around 100degC to soften kernels without significant gelatinization. Steam curing requires longer durations at higher temperatures, often exceeding 120degC, to ensure moisture penetration and structural transformation.

- Steaming Duration - Usually lasts 10 to 20 minutes, sufficient for surface moisture absorption and softening.

- Steam Curing Temperature - Maintains temperatures between 110degC and 130degC to activate enzymatic changes and enhance grain texture.

- Time-Temperature Balance - Proper control of exposure time and temperature is critical to avoid overprocessing or uneven curing effects.

Effects on Flavor and Aroma

Steaming grains preserves their natural nutty flavor and enhances aroma development through gentle heat exposure. Steam curing, by contrast, introduces a more intense, slightly altered flavor profile due to prolonged high pressure and temperature.

- Steaming maintains subtle flavors - Gentle heat treatment helps retain the grain's inherent taste and aroma compounds.

- Steam curing intensifies aroma - Extended exposure to steam under pressure modifies volatile compounds, boosting aroma strength.

- Flavor complexity varies - Steam curing can create deeper, more robust flavors compared to the milder profile from steaming.

Suitability for Different Types of Grains

| Steaming | Ideal for delicate grains such as rice and millet, preserving texture and minimizing nutrient loss. The moist heat penetrates slowly, allowing uniform softening without overcooking. Suitable for grains consumed directly after cooking or in dishes requiring gentle heat treatment. |

| Steam Curing | Preferred for harder grains like wheat, barley, and corn used in flour or malt production. High-temperature steam exposure enhances enzymatic activity, improving processing qualities and shelf life. Best for grains undergoing further processing rather than immediate consumption. |

Health and Safety Considerations

How do health and safety considerations differ between steaming and steam curing for grains? Steaming grains primarily reduces microbial load without introducing harmful residues, making it a safer option for direct consumption. Steam curing involves longer exposure to steam under pressure, which may pose risks of nutrient loss and requires strict control to prevent contamination and maintain safety standards.

Related Important Terms

Low-Pressure Grain Steaming

Low-pressure grain steaming enhances moisture absorption and enzyme activation, improving grain quality and feed digestibility compared to high-pressure steam curing. This method reduces thermal damage and preserves nutrient content, offering an energy-efficient alternative for grain processing in livestock feed production.

Dynamic Steam Curing Protocols

Dynamic steam curing protocols enhance grain quality by precisely controlling temperature, humidity, and exposure time to optimize starch gelatinization and enzyme activity. This approach surpasses traditional steaming by enabling uniform moisture penetration and improved structural integrity, resulting in better cooking performance and shelf life.

Moisture-Transfer Kinetics

Steaming involves exposing grains to high-temperature steam to rapidly increase moisture content through surface condensation and diffusion, while steam curing maintains sustained heat and humidity to promote uniform moisture transfer and starch gelatinization within the grain matrix. Moisture-transfer kinetics in steaming show faster initial absorption rates due to direct steam contact, whereas steam curing facilitates slower, more controlled moisture penetration enhancing grain texture and quality.

Enzymatic Activity Retention

Steaming grains enhances enzymatic activity retention by preserving key enzymes responsible for nutrient breakdown and bioavailability, unlike steam curing, which may denature enzymes due to prolonged exposure to high temperatures. Maintaining enzymatic activity during steaming supports better grain digestibility and improved nutritional quality in food processing.

Rapid Steam Curing Pulses

Rapid steam curing pulses accelerate moisture and heat penetration in grains, enhancing starch gelatinization and protein denaturation more effectively than traditional steaming methods. This process improves grain texture and shelf-life by ensuring uniform heat distribution and reducing curing time significantly.

Phytochemical Steam Modulation

Steaming modifies phytochemical profiles in grains by applying controlled heat and moisture, enhancing bioactive compound availability without degrading nutritional quality. Steam curing uses prolonged steam exposure to induce chemical changes, but may reduce sensitive phytochemicals, making steaming a preferred method for phytochemical steam modulation in grain processing.

Microbial Thermal Inactivation Index

Steaming and steam curing both utilize heat to reduce microbial contamination in grains, but steaming typically achieves higher Microbial Thermal Inactivation Index (MTII) values due to its rapid and direct heat application. This elevated MTII in steaming ensures more effective pathogen reduction compared to the prolonged, lower-temperature exposure seen in steam curing, enhancing grain safety and shelf life.

Steam-Infused Grain Texturization

Steam-infused grain texturization enhances gelatinization and moisture absorption, resulting in improved kernel expansion and softer texture compared to traditional steam curing. This method optimizes heat and moisture penetration, promoting uniform cooking and superior grain quality for milling and food applications.

Controlled Steam Penetration Mapping

Controlled steam penetration mapping enhances precision in steaming grains, ensuring even heat distribution and optimal moisture retention for improved grain quality. Steam curing relies on longer exposure at lower temperatures, which may reduce efficiency in moisture control compared to the targeted approach of controlled steam penetration mapping.

Steaming vs Steam Curing for grains. Infographic

cookingdiff.com

cookingdiff.com