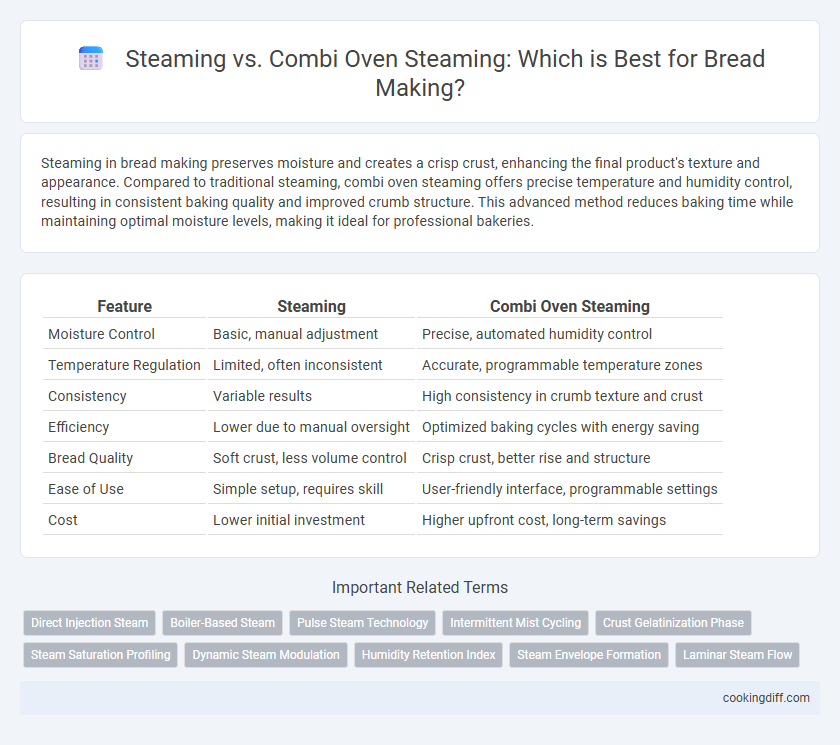

Steaming in bread making preserves moisture and creates a crisp crust, enhancing the final product's texture and appearance. Compared to traditional steaming, combi oven steaming offers precise temperature and humidity control, resulting in consistent baking quality and improved crumb structure. This advanced method reduces baking time while maintaining optimal moisture levels, making it ideal for professional bakeries.

Table of Comparison

| Feature | Steaming | Combi Oven Steaming |

|---|---|---|

| Moisture Control | Basic, manual adjustment | Precise, automated humidity control |

| Temperature Regulation | Limited, often inconsistent | Accurate, programmable temperature zones |

| Consistency | Variable results | High consistency in crumb texture and crust |

| Efficiency | Lower due to manual oversight | Optimized baking cycles with energy saving |

| Bread Quality | Soft crust, less volume control | Crisp crust, better rise and structure |

| Ease of Use | Simple setup, requires skill | User-friendly interface, programmable settings |

| Cost | Lower initial investment | Higher upfront cost, long-term savings |

Introduction to Steaming in Bread Making

Steaming plays a crucial role in bread making by promoting optimal crust formation and enhancing dough expansion. Traditional steaming introduces moisture directly into the oven environment, while combi oven steaming uses precise steam injection combined with controlled temperature and humidity settings. This technological advancement allows for consistent results, improved texture, and a shiny crust on artisan and commercial bread products.

What is a Traditional Steaming Method?

Traditional steaming in bread making involves introducing steam into a conventional oven or using a separate steam generator to create a humid environment during baking. This humid atmosphere prevents the crust from forming too quickly, allowing the bread to expand fully and develop a glossy, crisp crust.

Unlike combi oven steaming, which integrates precise steam and temperature controls digitally, traditional steaming relies on manual methods such as placing a pan of water in the oven or spraying water during the baking process. This method lacks the consistency and control offered by combi ovens, potentially affecting the uniformity of steam distribution and bread quality.

Understanding Combi Oven Steaming

How does combi oven steaming enhance bread making compared to traditional steaming methods? Combi oven steaming offers precise control over temperature and humidity, ensuring consistent crust formation and optimal crumb texture. This technology combines dry heat and steam, improving baking efficiency and product quality in professional kitchens.

Key Differences: Traditional Steaming vs Combi Oven Steaming

Traditional steaming for bread making involves applying steam directly into a sealed environment, which enhances crust development and moisture retention. This method requires precise manual control to maintain optimal humidity and temperature levels for consistent results.

Combi oven steaming integrates steam injection with convection heat, allowing automated regulation of humidity and temperature throughout the baking cycle. This advanced technology ensures uniform crust texture and efficient baking, reducing operator intervention and improving product consistency.

Impact on Bread Crust and Texture

Steaming in traditional ovens creates a moist environment that enhances crust formation by delaying the setting of the crust, allowing for better oven spring and a glossy, crisp finish. Combi oven steaming offers precise control over humidity and temperature, resulting in consistent crust texture and improved crumb softness through even heat distribution. The controlled steam injection in combi ovens reduces the risk of soggy crusts while maintaining optimal moisture for fluffy interior bread texture.

Steam Distribution and Consistency

Steam distribution in traditional steaming ovens tends to be uneven, causing inconsistencies in bread texture and crust formation. Combi oven steaming utilizes advanced steam injection systems that ensure uniform steam circulation, resulting in consistent bake quality across all loaves.

Combi ovens maintain precise humidity and temperature control, optimizing the steam environment for perfect crust development and crumb texture. This even steam distribution reduces the risk of soggy or dry spots, enhancing overall bread appearance and flavor. Consistent steam application in combi ovens also accelerates baking times, improving kitchen efficiency and throughput.

Control and Customization of Steam Levels

Steaming provides limited control over steam levels, often relying on manual adjustments that can affect consistency in bread texture. Combi oven steaming offers precise and customizable steam settings, allowing bakers to optimize crust formation and crumb softness for various bread types.

- Manual steam control - Traditional steaming methods require bakers to gauge moisture levels, leading to potential inconsistencies in bread quality.

- Precision settings - Combi ovens allow exact regulation of steam injection, improving reproducibility of baking results across batches.

- Customization for recipes - Advanced combi ovens enable tailored steam environments suited for specific bread varieties, enhancing both appearance and taste.

Energy Efficiency and Baking Time

Steaming bread in a traditional steam oven typically uses less energy per cycle compared to a combi oven, which combines steam and convection heat for faster baking. Combi ovens shorten baking time significantly by maintaining consistent humidity and temperature, improving bread texture and crust.

- Energy Efficiency of Steam Ovens - Traditional steam ovens consume less energy per baking cycle due to simpler heating mechanisms focused solely on steam generation.

- Faster Baking with Combi Ovens - Combi ovens reduce baking time by integrating steam and hot air, providing efficient heat transfer and moisture control.

- Improved Bread Quality in Combi Ovens - The precise humidity and temperature control in combi ovens enhances crumb structure and crust formation during shorter bake times.

Cost and Equipment Considerations

Steaming bread using traditional steamers often involves lower upfront equipment costs compared to combi oven steaming, which requires higher initial investment but offers multipurpose functionality. Operational expenses vary, with combi ovens generally consuming more energy but reducing labor costs through automation and precise climate control.

- Initial Investment - Traditional steamers are more affordable for small bakeries, whereas combi ovens demand significant capital expenditure.

- Energy Consumption - Combi ovens use advanced steam generation techniques that can increase electricity usage but improve baking consistency.

- Maintenance Costs - Steamers have simpler components leading to lower maintenance expenses, while combi ovens involve complex systems requiring specialized servicing.

Choosing between steaming methods depends on budget constraints and desired production efficiency in bread making.

Related Important Terms

Direct Injection Steam

Direct injection steam in bread making provides rapid, precise humidity control by injecting steam directly into the oven chamber, enhancing crust development and oven spring compared to traditional combi oven steaming methods. This technique reduces condensation and energy consumption while improving crumb texture and crust crispness in artisan and commercial bread production.

Boiler-Based Steam

Boiler-based steam systems in bread making deliver consistent, high-pressure steam essential for optimal crust formation and oven spring, outperforming combi oven steaming that often provides variable humidity levels. This precise steam control enhances loaf volume and crust crispness by maintaining ideal moisture and temperature conditions throughout the baking process.

Pulse Steam Technology

Pulse Steam Technology in combi ovens delivers precise steam injection that enhances crust formation and crumb development in bread making, outperforming traditional steaming methods by maintaining optimal humidity levels. This controlled steam pulse optimizes heat transfer and surface moisture, resulting in consistent oven spring and superior bread texture.

Intermittent Mist Cycling

Intermittent mist cycling in combi oven steaming precisely controls humidity levels, enhancing crust formation and crumb structure in bread making. Traditional steaming lacks this dynamic moisture regulation, often resulting in less consistent crust quality and moisture retention.

Crust Gelatinization Phase

Steaming in traditional bread baking ensures a humid environment that delays crust formation, allowing the dough to expand fully before gelatinization. Combi oven steaming precisely controls temperature and humidity, optimizing the crust gelatinization phase to produce a thicker, glossy crust with improved texture and extended freshness.

Steam Saturation Profiling

Steam saturation profiling in combi oven steaming ensures consistent moisture levels within the baking environment, promoting optimal yeast activity and crust development for superior bread texture. Traditional steaming methods often lack precise control, resulting in uneven steam distribution that can cause irregular crumb structure and lower volume in bread production.

Dynamic Steam Modulation

Dynamic steam modulation in combi oven steaming provides precise humidity control, enhancing crust development and crumb texture in bread making. Traditional steaming methods lack this level of steam control, often resulting in inconsistent baking outcomes and less optimal crust quality.

Humidity Retention Index

Steaming in bread making enhances crust development by maintaining high humidity levels within the oven, which is critical for proper oven spring and crust texture. Combi oven steaming offers precise control over temperature and humidity retention index, ensuring consistent moisture levels that improve dough expansion and produce superior bread crust quality.

Steam Envelope Formation

Steaming in traditional methods creates a less uniform steam envelope around the dough, resulting in inconsistent crust texture and oven spring. Combi oven steaming generates a controlled, consistent steam envelope that enhances crust crispness and optimal dough expansion, improving bread quality.

Steaming vs Combi Oven Steaming for bread making. Infographic

cookingdiff.com

cookingdiff.com