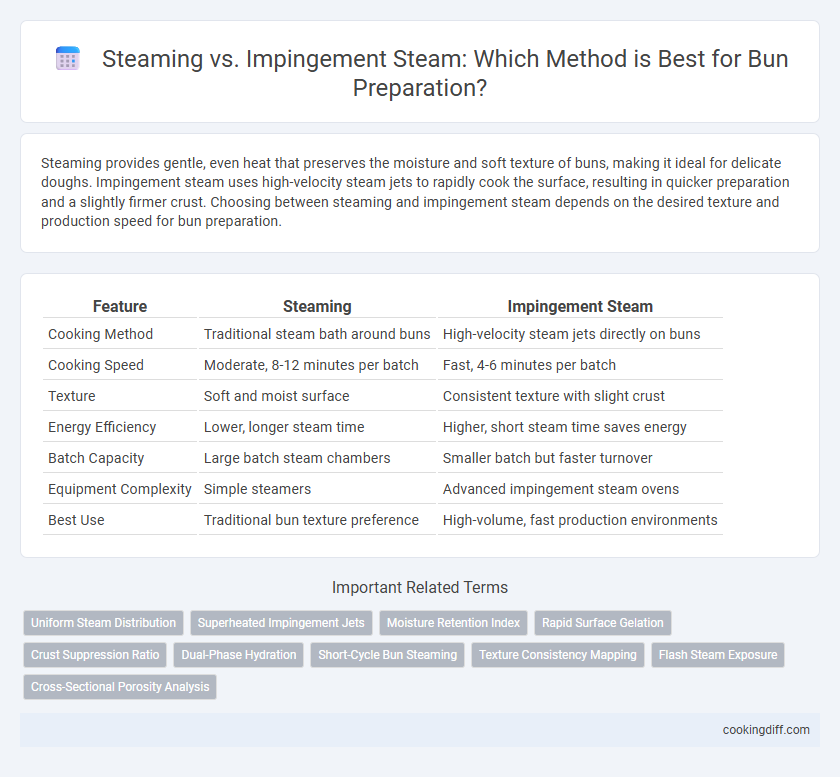

Steaming provides gentle, even heat that preserves the moisture and soft texture of buns, making it ideal for delicate doughs. Impingement steam uses high-velocity steam jets to rapidly cook the surface, resulting in quicker preparation and a slightly firmer crust. Choosing between steaming and impingement steam depends on the desired texture and production speed for bun preparation.

Table of Comparison

| Feature | Steaming | Impingement Steam |

|---|---|---|

| Cooking Method | Traditional steam bath around buns | High-velocity steam jets directly on buns |

| Cooking Speed | Moderate, 8-12 minutes per batch | Fast, 4-6 minutes per batch |

| Texture | Soft and moist surface | Consistent texture with slight crust |

| Energy Efficiency | Lower, longer steam time | Higher, short steam time saves energy |

| Batch Capacity | Large batch steam chambers | Smaller batch but faster turnover |

| Equipment Complexity | Simple steamers | Advanced impingement steam ovens |

| Best Use | Traditional bun texture preference | High-volume, fast production environments |

Introduction to Bun Preparation: Steaming Methods

| Steaming involves gentle, moist heat that evenly cooks buns, preserving softness and moisture crucial for quality texture. |

| Impingement steam uses high-velocity steam jets for rapid heat transfer, resulting in faster cooking times and a slightly firmer bun surface. |

| Choosing between traditional steaming and impingement steam affects bun preparation efficiency, texture, and moisture retention, impacting final product quality in bakery operations. |

What is Traditional Steaming?

Traditional steaming uses moist heat generated by boiling water to cook buns gently and evenly. This process preserves the bun's soft texture and enhances its moisture retention.

- Direct steam exposure - Buns are placed on perforated trays and exposed to steam rising naturally from boiling water below.

- Longer cook times - The heat transfer occurs slowly, requiring more time to fully cook the buns compared to impingement steam methods.

- Soft, fluffy texture - The consistent, gentle steam environment helps maintain the desired tender crumb and moist interior of the buns.

Understanding Impingement Steam Technology

Impingement steam technology enhances bun preparation by directing high-velocity steam jets directly onto the dough surface, resulting in faster and more even cooking compared to traditional steaming. This method improves texture and moisture retention in buns by promoting efficient heat transfer and consistent steam distribution.

- Targeted Steam Application - High-velocity jets focus steam precisely, reducing cooking time and improving bun quality.

- Improved Heat Transfer - Direct steam impingement accelerates heat penetration into the dough, ensuring uniform baking.

- Enhanced Moisture Retention - Controlled steam exposure prevents over-saturation, maintaining optimal bun texture.

Understanding impingement steam technology allows bakeries to optimize bun preparation for superior quality and production efficiency.

Comparing Cooking Times: Steaming vs Impingement Steam

Steaming typically requires 8-12 minutes to cook buns thoroughly, allowing even heat distribution through moist steam. Impingement steam accelerates cooking by directing high-velocity steam jets, reducing cooking time to about 4-6 minutes while maintaining bun texture. This efficiency makes impingement steam ideal for high-volume production without compromising quality.

Impact on Bun Texture and Appearance

Steaming preserves the bun's moisture, resulting in a soft, pillowy texture with a smooth, shiny surface. The gentle heat prevents crust formation, maintaining the bun's tender and fluffy interior.

Impingement steam uses high-velocity steam jets that create a firmer crust and slightly denser texture on the bun. This method enhances the bun's golden-brown appearance and provides a more pronounced outer structure.

Flavor Retention: Which Method Wins?

Steaming preserves the natural moisture and subtle flavors of buns by using gentle heat, preventing the loss of essential oils and aromas. Impingement steam, with its high-velocity steam jets, often leads to uneven cooking and potential flavor dilution due to rapid moisture evaporation.

Flavor retention tends to be higher in traditional steaming, which maintains the bun's soft texture and rich taste profile. Impingement steam can result in a less nuanced flavor, as the intense steam flow may wash away delicate taste compounds during preparation.

Nutritional Differences in Steamed Buns

Steaming preserves more vitamins and minerals in buns compared to impingement steam, which subjects dough to higher temperatures and faster cooking times. This gentler method helps retain nutrients like B vitamins and antioxidants that are sensitive to heat.

Impingement steam uses high-velocity steam jets that cook buns quickly but can degrade sensitive nutrients, reducing the overall nutritional value. The nutrient loss is particularly significant for water-soluble vitamins and phytonutrients. Choosing traditional steaming enhances the retention of essential nutrients, making steamed buns healthier for consumption.

Equipment and Space Considerations

Steaming equipment generally requires less space and simpler setup compared to impingement steam systems, which need specialized nozzles and more complex infrastructure. Impingement steam ovens offer faster cooking times but demand higher initial investment and maintenance space.

- Steaming equipment compactness - Traditional steamers often have a smaller footprint and are easier to install in limited kitchen spaces.

- Impingement steam infrastructure - Requires advanced components and more space for steam distribution and ventilation systems.

- Maintenance considerations - Steaming units typically need less frequent maintenance than impingement steam ovens due to simpler mechanical parts.

Energy Efficiency and Operating Costs

How does steaming compare to impingement steam in terms of energy efficiency and operating costs for bun preparation? Traditional steaming generally consumes more energy due to longer cooking times and less direct heat transfer, leading to higher operating costs. Impingement steam technology enhances energy efficiency by delivering steam with force, reducing cooking time and lowering overall energy consumption and expenses.

Related Important Terms

Uniform Steam Distribution

Impingement steam delivers targeted high-velocity steam jets that create rapid, uniform heat penetration ideal for consistent bun texture and rise; traditional steaming often results in uneven steam distribution leading to irregular crumb structure. Optimized impingement systems enhance moisture retention and surface crispness by maintaining consistent steam coverage across all buns during the baking cycle.

Superheated Impingement Jets

Superheated impingement jets deliver targeted, high-velocity steam that rapidly heats bun surfaces, ensuring a crisp crust and uniform interior texture, unlike traditional steaming which often results in uneven moisture penetration. This method enhances surface browning and reduces cooking time by maintaining precise temperature control and maximizing heat transfer efficiency.

Moisture Retention Index

Steaming offers a higher Moisture Retention Index compared to impingement steam, ensuring buns remain soft and moist during preparation. Impingement steam, while faster, can cause uneven moisture distribution, leading to drier bun surfaces.

Rapid Surface Gelation

Rapid surface gelation during steaming creates a uniform, soft crust essential for high-quality buns, while impingement steam accelerates this process by directing high-velocity steam jets for faster heat transfer and consistent texture. The impingement method enhances moisture retention and reduces steaming time, improving bun appearance and shelf life compared to traditional steaming techniques.

Crust Suppression Ratio

Steaming offers a higher crust suppression ratio compared to impingement steam, resulting in softer and more uniform buns by minimizing surface dryness during the baking process. Impingement steam, while effective for quick moisture application, generally produces a lower crust suppression ratio, leading to slightly firmer crusts in bun preparation.

Dual-Phase Hydration

Dual-phase hydration in steaming ensures buns absorb moisture gradually, resulting in a soft, fluffy texture without sogginess. Impingement steam methods provide rapid surface heat and moisture transfer, but may cause uneven hydration, affecting bun quality and texture consistency.

Short-Cycle Bun Steaming

Short-cycle bun steaming utilizes high-heat, direct steam injection to rapidly cook and hydrate buns, preserving softness and reducing overall preparation time compared to traditional steaming methods. Impingement steam relies on forced convection to evenly distribute steam but typically requires longer cycles, making it less efficient for high-volume bun production.

Texture Consistency Mapping

Steaming produces softer, moister buns with consistent crumb texture, while impingement steam delivers a firmer crust and enhanced surface browning through targeted high-velocity steam jets; texture consistency mapping reveals steaming offers uniform internal moisture distribution, whereas impingement results in greater textural contrast between crust and crumb. This analysis aids in selecting the optimal method for desired bun characteristics in commercial bakery operations.

Flash Steam Exposure

Flash steam exposure in impingement steam systems rapidly delivers high-velocity steam directly onto buns, enhancing heat transfer and reducing cooking time compared to traditional steaming methods. This targeted steam application improves bun texture by creating a crispier crust while maintaining a soft interior, optimizing both quality and production efficiency.

Steaming vs Impingement Steam for bun preparation. Infographic

cookingdiff.com

cookingdiff.com