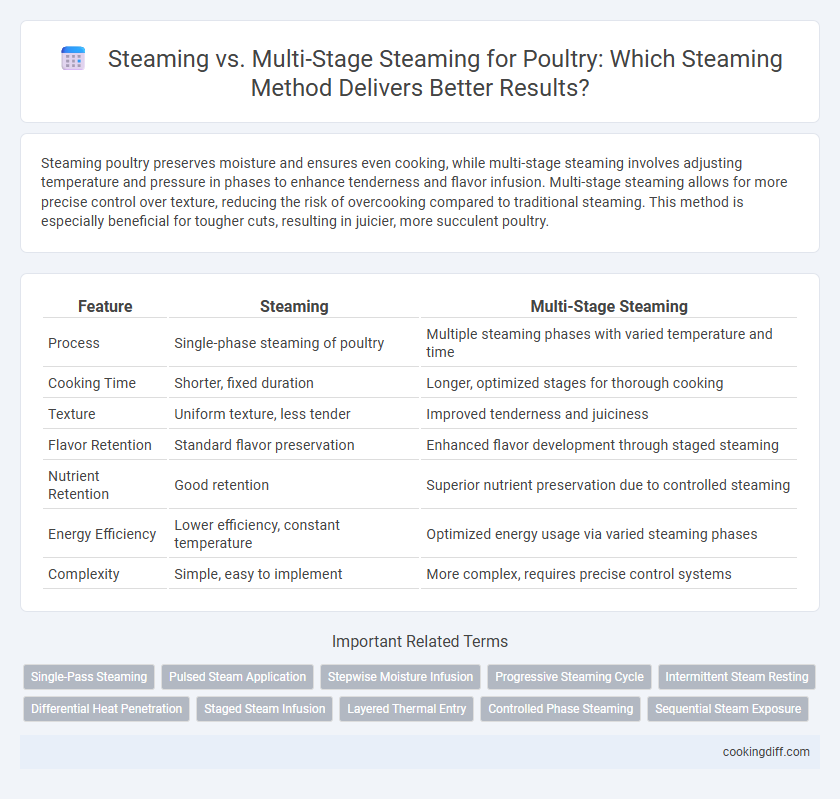

Steaming poultry preserves moisture and ensures even cooking, while multi-stage steaming involves adjusting temperature and pressure in phases to enhance tenderness and flavor infusion. Multi-stage steaming allows for more precise control over texture, reducing the risk of overcooking compared to traditional steaming. This method is especially beneficial for tougher cuts, resulting in juicier, more succulent poultry.

Table of Comparison

| Feature | Steaming | Multi-Stage Steaming |

|---|---|---|

| Process | Single-phase steaming of poultry | Multiple steaming phases with varied temperature and time |

| Cooking Time | Shorter, fixed duration | Longer, optimized stages for thorough cooking |

| Texture | Uniform texture, less tender | Improved tenderness and juiciness |

| Flavor Retention | Standard flavor preservation | Enhanced flavor development through staged steaming |

| Nutrient Retention | Good retention | Superior nutrient preservation due to controlled steaming |

| Energy Efficiency | Lower efficiency, constant temperature | Optimized energy usage via varied steaming phases |

| Complexity | Simple, easy to implement | More complex, requires precise control systems |

Understanding Traditional Steaming for Poultry

Traditional steaming for poultry involves cooking the meat using steam generated from boiling water, which maintains moisture and tenderness without direct contact with water. This method ensures even heat distribution while preserving the natural flavors and nutrients of the poultry. Understanding the benefits of traditional steaming helps in comparing its simplicity with the more complex temperature controls used in multi-stage steaming techniques.

What is Multi-Stage Steaming?

Multi-stage steaming for poultry involves cooking the meat at different temperatures in sequential phases to ensure optimal texture and moisture retention. This method contrasts with single-stage steaming, which maintains a constant temperature throughout the process.

By gradually increasing the steam temperature, multi-stage steaming enhances flavor infusion and helps prevent overcooking or dryness. It is especially effective for large poultry cuts, improving overall juiciness and tenderness compared to traditional steaming techniques.

Key Differences Between Steaming and Multi-Stage Steaming

What are the key differences between steaming and multi-stage steaming for poultry? Steaming involves cooking poultry at a constant temperature to retain moisture, while multi-stage steaming uses varying temperatures in phases to optimize texture and flavor development. Multi-stage steaming enhances tenderness and juiciness by gradually adjusting heat settings for precise control during the cooking process.

Moisture Retention in Poultry: Steaming vs Multi-Stage Steaming

Steaming poultry preserves moisture by cooking at a consistent temperature, preventing drying and ensuring juiciness. Multi-stage steaming enhances this by adjusting temperatures in phases, further optimizing moisture retention and texture.

- Steaming maintains consistent heat - This uniform temperature prevents moisture loss, resulting in tender and juicy poultry.

- Multi-stage steaming uses temperature variation - Gradual changes reduce muscle contraction, minimizing water expulsion during cooking.

- Enhanced moisture retention improves flavor - Poultry cooked via multi-stage steaming exhibits superior juiciness and mouthfeel compared to single-stage steaming.

Flavor Development: Comparing Both Methods

| Steaming | Preserves the natural flavor and moisture of poultry by gently cooking with steam, resulting in tender meat with a subtle, clean taste. |

| Multi-Stage Steaming | Enhances flavor complexity through sequential steaming phases that allow seasoning to penetrate deeper and develop richer aromatic profiles in the poultry. |

| Flavor Development Comparison | Multi-stage steaming offers superior flavor depth and intensity compared to single-stage steaming by facilitating gradual absorption of herbs and spices, maximizing taste infusion without drying the meat. |

Texture and Tenderness: Which Method Wins?

Multi-stage steaming enhances poultry texture by gradually adjusting temperature, resulting in superior tenderness compared to traditional steaming. This method reduces muscle fiber contraction, preserving juiciness and preventing overcooking.

- Improved tenderness - Multi-stage steaming allows collagen breakdown at lower temperatures, making meat more tender.

- Better moisture retention - The controlled heat application minimizes moisture loss, maintaining juicy poultry.

- Enhanced texture - Gradual steaming produces consistent fiber softening, improving overall mouthfeel.

Nutrient Preservation in Poultry: A Comparative Analysis

Steaming poultry retains more water-soluble vitamins such as B-complex and vitamin C compared to multi-stage steaming, which may expose the meat to varying temperatures causing some nutrient degradation. The gentle, consistent heat in traditional steaming helps preserve essential minerals like potassium and phosphorus, enhancing poultry's nutritional profile.

Multi-stage steaming introduces phases of higher heat that can reduce antioxidant levels and heat-sensitive nutrients in poultry. However, it may improve the texture by breaking down connective tissues more effectively than single-stage steaming. Choosing the method depends on balancing nutrient preservation with desired culinary outcomes.

Cooking Times: Steaming Versus Multi-Stage Steaming

Steaming poultry typically requires a consistent cooking time between 20 to 30 minutes depending on the bird's size, ensuring even heat distribution and moisture retention. Multi-stage steaming involves alternating high and low steam phases, which can reduce overall cooking time by up to 15%, while enhancing texture and juiciness. This method optimizes heat transfer, allowing for more efficient cooking without sacrificing quality.

Equipment and Setup: Single Steaming vs Multi-Stage Steaming

Single steaming requires basic equipment such as a large steam cooker or a conventional steam oven, making setup straightforward and cost-effective for small to medium poultry batches. Multi-stage steaming involves complex systems with multiple chambers or adjustable temperature zones, enabling precise control over cooking phases for optimized poultry texture and flavor.

- Single Steaming Equipment - Typically consists of one steam chamber with uniform temperature control suitable for consistent cooking.

- Multi-Stage Steaming Setup - Uses segmented chambers or programmable steamers to vary temperature and humidity through different cooking stages.

- Operational Complexity - Multi-stage steaming demands more advanced controls and calibration to manage each phase efficiently compared to single steaming.

Choosing between single and multi-stage steaming depends on volume, required cooking precision, and equipment budget constraints.

Related Important Terms

Single-Pass Steaming

Single-pass steaming in poultry ensures uniform cooking by maintaining consistent temperature and humidity, which enhances moisture retention and texture quality. Compared to multi-stage steaming, it reduces processing time and energy consumption while preventing overcooking and nutrient loss.

Pulsed Steam Application

Pulsed steam application in poultry processing enhances heat penetration and moisture retention compared to traditional continuous steaming, resulting in improved texture and juiciness. Multi-stage steaming with pulsed steam optimizes energy efficiency and reduces cooking time by alternating steam intensity, ensuring even heat distribution and minimizing overcooking.

Stepwise Moisture Infusion

Stepwise moisture infusion in multi-stage steaming allows gradual absorption of steam, resulting in uniformly tender and juicy poultry compared to conventional single-stage steaming. Controlled temperature and humidity adjustments during each stage enhance moisture retention and flavor penetration, optimizing texture and succulence.

Progressive Steaming Cycle

Progressive steaming cycle enhances poultry cooking by gradually increasing steam temperature and pressure, ensuring even heat distribution and moisture retention throughout the process. This approach contrasts with multi-stage steaming, which uses preset steam phases but lacks the continuous adjustment of conditions, resulting in less consistent tenderness and juiciness.

Intermittent Steam Resting

Intermittent steam resting in multi-stage steaming enhances poultry tenderness by allowing steam to penetrate evenly during rest periods, reducing moisture loss compared to continuous steaming. This method optimizes heat transfer and maintains juiciness, resulting in a more consistently cooked product with improved texture and flavor retention.

Differential Heat Penetration

Steaming provides consistent heat penetration primarily through moist convective heat transfer, ensuring even cooking of poultry surfaces but slower internal temperature rise. Multi-stage steaming alternates between varying steam pressures and temperatures, enhancing differential heat penetration by accelerating internal heat transfer and reducing overall cooking time while maintaining juiciness.

Staged Steam Infusion

Staged steam infusion in multi-stage steaming for poultry enhances heat penetration and moisture retention by progressively increasing steam temperature and pressure, resulting in more uniform cooking and improved texture compared to single-stage steaming. This method reduces cooking time and minimizes nutrient loss, optimizing poultry quality and efficiency in commercial processing.

Layered Thermal Entry

Layered thermal entry in multi-stage steaming allows precise temperature control at varying depths of poultry, ensuring even cooking and enhanced moisture retention. Standard steaming often results in uneven heat distribution, compromising texture and flavor compared to the progressive heat penetration achieved in multi-stage processes.

Controlled Phase Steaming

Controlled Phase Steaming offers precise temperature and humidity regulation, enhancing poultry moisture retention and even cooking compared to traditional multi-stage steaming. This method reduces cooking time variability and minimizes nutrient loss, resulting in superior texture and flavor quality.

Steaming vs Multi-Stage Steaming for poultry. Infographic

cookingdiff.com

cookingdiff.com