Steaming creates a moist environment that helps bread develop a crisp crust and a soft interior by preventing the dough surface from drying out during baking. Steam convection combines this moisture with hot air circulation, promoting even heat distribution and faster baking times while enhancing crust color and texture. Choosing between steaming and steam convection depends on the desired crust characteristics and baking efficiency for artisan or commercial bread production.

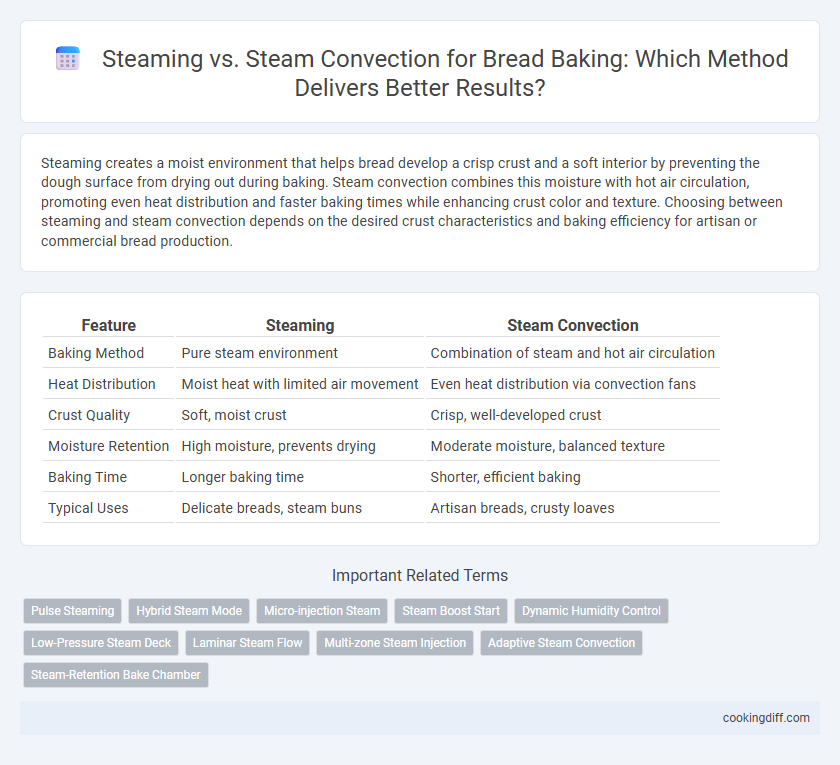

Table of Comparison

| Feature | Steaming | Steam Convection |

|---|---|---|

| Baking Method | Pure steam environment | Combination of steam and hot air circulation |

| Heat Distribution | Moist heat with limited air movement | Even heat distribution via convection fans |

| Crust Quality | Soft, moist crust | Crisp, well-developed crust |

| Moisture Retention | High moisture, prevents drying | Moderate moisture, balanced texture |

| Baking Time | Longer baking time | Shorter, efficient baking |

| Typical Uses | Delicate breads, steam buns | Artisan breads, crusty loaves |

Introduction to Bread Baking Methods

What are the key differences between steaming and steam convection in bread baking? Steaming involves injecting pure steam into the oven, creating a moist environment that helps develop a glossy crust and enhances oven spring. Steam convection combines steam injection with circulated hot air, providing even heat distribution for consistent browning and texture throughout the loaf.

What is Traditional Steaming in Bread Baking?

Traditional steaming in bread baking involves introducing water vapor directly into the oven chamber to create a humid environment. This method helps develop a thin, crispy crust while allowing the bread to expand fully during the initial baking phase.

Steam convection, by contrast, combines steam with circulated hot air to promote even baking and crust formation. However, traditional steaming remains favored for its simplicity and ability to enhance oven spring and crust texture.

Understanding Steam Convection Technology

Steam convection technology combines the benefits of steam injection with hot air circulation, providing even heat distribution and moisture retention during bread baking. This process enhances crust formation and improves the overall texture and volume of the bread.

Compared to traditional steaming, steam convection ensures a controlled environment where steam and air flow simultaneously, reducing baking time and preventing uneven cooking. Bakers achieve consistent results with a crisp, golden crust and soft interior using this advanced method.

Key Differences: Steaming vs Steam Convection

Steaming in bread baking involves injecting pure steam into the oven to create a humid environment that enhances crust development and oven spring. Steam convection combines steam injection with forced air circulation, ensuring even heat distribution and faster, more uniform baking. Key differences include moisture control where steaming focuses on humidity alone, while steam convection balances humidity with consistent temperature and airflow for better crust texture and crumb structure.

Impact on Bread Crust Formation

| Steaming creates a moist environment that delays crust formation, allowing bread to expand fully before a crust sets, resulting in a thinner, crispier crust. Steam convection combines steam with hot air circulation, promoting uniform heat distribution and a thicker, crunchier crust due to faster moisture evaporation. The ideal method depends on desired crust characteristics, with pure steaming enhancing volume and soft crusts, while steam convection favors well-browned, robust crust textures. |

Effect on Bread Texture and Crumb

Steaming enhances bread texture by creating a moist environment that promotes a glossy, crispy crust and a soft crumb. Steam convection circulates heat and moisture evenly, resulting in consistent crumb structure and improved oven spring.

- Steaming intensity - Generates a shiny, crackly crust by delaying crust formation and enabling maximum loaf expansion.

- Steam convection effect - Combines moist heat and airflow to evenly bake bread, producing a light and airy crumb.

- Crust and crumb balance - Steaming alone may yield uneven texture, while steam convection optimizes both crust crispness and crumb softness.

Flavor Profiles: How Moisture Alters Taste

Steaming preserves the bread's natural moisture, resulting in a softer crumb and enhanced subtle sweetness. Steam convection combines moisture with hot air circulation, creating a crisp crust while maintaining a tender interior.

- Steaming - Retains moisture inside the dough, intensifying the bread's inherent flavors.

- Steam convection - Promotes caramelization and Maillard reactions, enriching the crust's complex taste.

- Flavor development - Moisture levels directly impact the balance between crust texture and crumb softness.

Choosing between steaming and steam convection depends on the desired flavor profile and texture contrast in the final bread.

Equipment Needed for Each Method

Steaming bread requires a simple setup such as a pot with a lid or a steam oven that generates high humidity for optimal crust formation. Steam convection baking demands specialized convection ovens equipped with steam injection systems to maintain consistent temperature and moisture levels. Both methods rely on precise equipment to create the ideal environment, but steam convection offers more control and uniform heat distribution compared to basic steaming tools.

Energy Efficiency and Baking Time Comparison

Steaming uses direct moisture injection, which conserves energy by reducing baking time and maintaining optimal humidity for crust formation, while steam convection combines steam with hot air circulation, often consuming more energy but promoting even heat distribution. Energy efficiency in steaming typically results in faster baking cycles compared to steam convection ovens.

Steaming reduces overall baking time by increasing heat transfer through moisture condensation, enabling bread to rise quickly and develop a crisp crust without excessive energy use. Steam convection ovens extend baking times as they balance moisture and air circulation, which can increase power consumption. Choosing steaming methods often leads to lower energy costs and faster production in commercial bread baking settings.

Related Important Terms

Pulse Steaming

Pulse steaming introduces intermittent bursts of steam during bread baking, promoting optimal crust formation by balancing moisture retention and surface drying. Compared to continuous steam convection, pulse steaming enhances oven spring and crust texture through precise steam control that prevents excess sogginess while maintaining a crisp, golden finish.

Hybrid Steam Mode

Hybrid steam mode combines the benefits of steaming and steam convection, enhancing crust development and crumb texture in bread baking. This method ensures optimal moisture retention while promoting even heat distribution, resulting in a superior rise and a crisp, golden crust.

Micro-injection Steam

Micro-injection steam technology enhances bread baking by delivering precise, controlled bursts of steam directly into the oven chamber, promoting optimal crust formation and moisture retention. Steam convection combines steam with hot air circulation to ensure even baking, but micro-injection steam offers superior control over steam distribution, resulting in consistently better texture and volume.

Steam Boost Start

Steam Boost Start enhances bread crust development by injecting high humidity steam during the initial baking phase, optimizing oven spring and surface gelatinization. Compared to traditional steam convection, this method provides more controlled moisture, resulting in a crispier crust and improved volume.

Dynamic Humidity Control

Dynamic humidity control in steaming provides precise moisture regulation, creating an optimal environment for bread crust development and oven spring. Steam convection combines steam and hot air circulation, enhancing heat transfer efficiency but may compromise consistent humidity levels crucial for bread texture and crust quality.

Low-Pressure Steam Deck

Low-pressure steam deck ovens provide gentle, evenly distributed moisture that enhances crust development and improves oven spring compared to high-pressure steam convection methods. This controlled steam environment prevents crust cracking and promotes a glossy, tender crumb ideal for artisanal bread baking.

Laminar Steam Flow

Laminar steam flow in bread baking ensures gentle and even moisture distribution, enhancing crust development and oven spring without disrupting dough structure, unlike turbulent steam convection which can cause uneven baking and surface flaws. Optimizing laminar steam flow improves crust texture by preventing excessive condensation and promoting uniform heat transfer during the critical early stages of baking.

Multi-zone Steam Injection

Multi-zone steam injection enhances bread baking by delivering precise steam levels in different oven zones, improving crust texture and oven spring compared to traditional steam convection. This targeted moisture control ensures consistent heat distribution and optimal fermentation, resulting in superior loaf volume and crust color.

Adaptive Steam Convection

Adaptive Steam Convection enhances bread baking by combining precise steam injection with controlled hot air circulation, ensuring an even crust formation and optimal crumb texture. This technique outperforms traditional steaming by dynamically adjusting humidity and temperature levels, resulting in consistently superior loaf volume and crust crispness.

Steaming vs Steam Convection for bread baking. Infographic

cookingdiff.com

cookingdiff.com