Steaming offers a gentle cooking method that preserves nutrients and natural flavors, ideal for batch cooking with consistent results. A Dim Sum Steaming Cabinet provides specialized compartments and uniform steam distribution, enabling efficient preparation of multiple items simultaneously, perfect for large-scale or commercial use. Choosing between the two depends on batch size and precision needs, with steaming suited for smaller batches and steaming cabinets optimized for volume and variety.

Table of Comparison

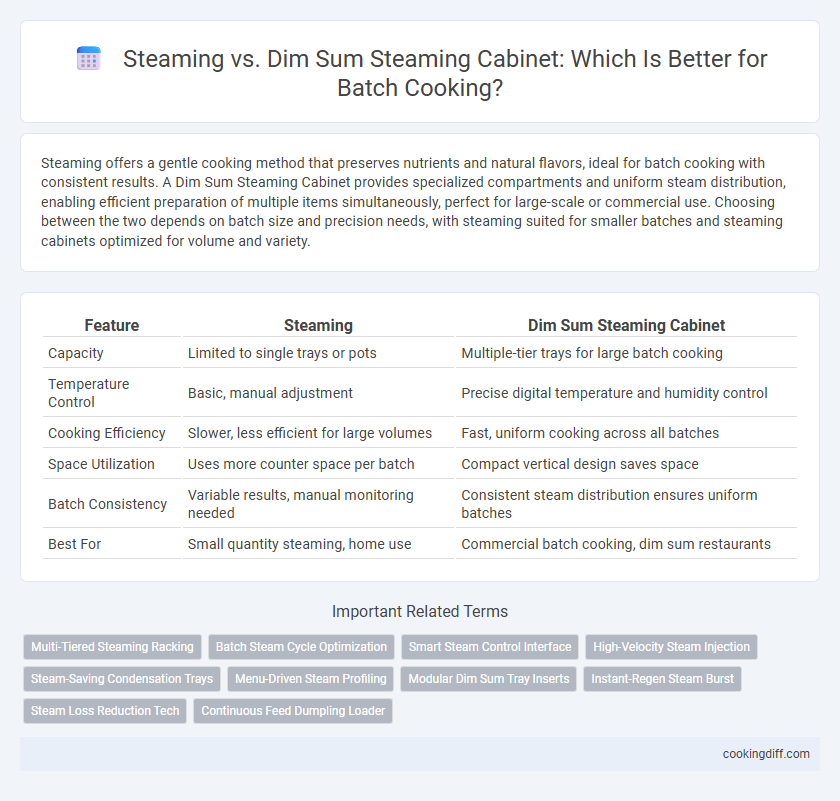

| Feature | Steaming | Dim Sum Steaming Cabinet |

|---|---|---|

| Capacity | Limited to single trays or pots | Multiple-tier trays for large batch cooking |

| Temperature Control | Basic, manual adjustment | Precise digital temperature and humidity control |

| Cooking Efficiency | Slower, less efficient for large volumes | Fast, uniform cooking across all batches |

| Space Utilization | Uses more counter space per batch | Compact vertical design saves space |

| Batch Consistency | Variable results, manual monitoring needed | Consistent steam distribution ensures uniform batches |

| Best For | Small quantity steaming, home use | Commercial batch cooking, dim sum restaurants |

Introduction: Steaming Methods in Professional Kitchens

Steaming is a preferred cooking method in professional kitchens for its ability to preserve nutrients and enhance natural flavors. Traditional dim sum steaming cabinets are designed for small, delicate portions but may limit capacity for larger batch cooking. In contrast, industrial steaming cabinets offer greater volume and precise temperature control, optimizing efficiency for high-demand culinary environments.

What is a Steaming Cabinet?

A steaming cabinet is a specialized appliance designed for efficient batch cooking by using steam to evenly cook large quantities of food. It maintains precise temperature and humidity control, making it ideal for various commercial kitchen applications.

- High Capacity - Steaming cabinets can accommodate multiple trays of food simultaneously, optimizing kitchen workflow.

- Consistent Heat Distribution - The cabinet ensures uniform steam circulation for even cooking results across all batches.

- Versatility - Suitable for steaming vegetables, seafood, meats, and dough-based items with precise moisture retention.

Overview of Traditional Dim Sum Steaming Cabinets

Traditional dim sum steaming cabinets are designed for high-volume cooking, maintaining consistent temperature and humidity to ensure delicate texture and flavor. These cabinets typically use multiple stacked trays allowing simultaneous steaming of various dishes, optimizing kitchen efficiency.

- High capacity - Enables steaming large batches of dim sum items at once, ideal for busy restaurants.

- Moisture retention - Built to maintain optimal humidity levels to prevent drying out of delicate dim sum.

- Compact design - Stacked trays maximize vertical space for efficient use of kitchen area.

Traditional dim sum steaming cabinets provide reliable performance specifically tailored for authentic batch cooking needs.

Comparing Steaming Techniques: Batch Cooking vs. Dim Sum Steaming

Batch cooking using a steaming cabinet focuses on efficiently preparing large quantities of diverse dishes simultaneously, optimizing time and energy usage in commercial kitchens. Dim sum steaming cabinets, however, specialize in maintaining precise humidity and temperature levels for delicate, small-sized portions, preserving texture and flavor integrity.

The robust design of batch cooking steamers supports multiple trays and varied menu items, ensuring versatility and scalability in food production. Dim sum steamers feature compartmentalized trays tailored for uniform steam distribution, crucial for traditional Cantonese delicacies that require consistent heat exposure.

Pros and Cons of Standard Steaming Cabinets

Standard steaming cabinets offer consistent temperature control and uniform steam distribution, making them ideal for batch cooking a variety of foods simultaneously. Their spacious interiors allow for large-scale preparation, reducing cooking time and maintaining food quality across multiple trays.

However, these cabinets can be less energy-efficient compared to specialized equipment and may require more maintenance due to their larger steam generation systems. They lack the specific compartmentalization found in dim sum steaming cabinets, which can limit their versatility for cooking delicate or distinct small portions efficiently.

Advantages of Dim Sum Steaming Cabinets for Batch Cooking

| Dim Sum steaming cabinets offer superior capacity for batch cooking, accommodating multiple trays simultaneously to increase efficiency. |

| The controlled steam environment ensures even heat distribution, preserving texture and flavor across a large volume of food. |

| These cabinets provide precise temperature and humidity control, reducing cooking time and energy consumption compared to conventional steaming methods. |

Key Features: Temperature, Humidity, and Control

Steaming cabinets designed specifically for batch cooking offer precise temperature control ranging from 140degF to 212degF, ensuring consistent heat distribution essential for large-scale food preparation. Humidity levels within these cabinets can be finely adjusted, maintaining optimal moisture to preserve the texture and flavor of steamed items.

Dim sum steaming cabinets specialize in maintaining high humidity and consistent temperatures ideal for delicate, small portions, typically featuring digital controls for ease of operation. These cabinets often include multiple stacking trays, allowing efficient steaming of numerous dim sum pieces simultaneously without compromising quality. Advanced control systems in dim sum steamers ensure uniform steam circulation, critical for batch cooking consistency and food safety.

Efficiency and Capacity: Which Steamer Suits Your Needs?

Steaming cabinets designed specifically for dim sum offer higher capacity and consistent temperature control, making them ideal for large batch cooking with diverse items. Traditional steamers, while efficient for smaller quantities, often lack the volume and precise humidity regulation needed for extensive meal preparation. Choosing between the two depends on your batch size requirements and the importance of maintaining uniform cooking conditions.

Maintenance and Cleaning: Steaming vs. Dim Sum Cabinets

Steaming cabinets require regular descaling and wiping to prevent mineral buildup, ensuring optimal steam flow and food quality. Dim sum steaming cabinets have specialized racks and compartments that necessitate detailed cleaning to avoid residual food particles and maintain hygiene.

- Steaming Cabinets Maintenance - These units need frequent descaling and steam head cleaning to prevent clogging and preserve efficient operation.

- Dim Sum Cabinet Cleaning - Targeted cleaning of compartments and racks is essential to remove food debris and prevent bacterial growth in dim sum steamers.

- Material Considerations - Stainless steel surfaces in both cabinets simplify wiping and resist corrosion, reducing long-term maintenance efforts.

Related Important Terms

Multi-Tiered Steaming Racking

Multi-tiered steaming racks maximize cooking capacity in batch steaming by allowing simultaneous preparation of various dishes without flavor transfer, optimizing space within steaming cabinets. Compared to traditional dim sum steaming cabinets, these racks offer enhanced heat distribution and efficient steam circulation, ensuring consistent cooking results across multiple layers.

Batch Steam Cycle Optimization

Batch steam cycle optimization in steaming vs dim sum steaming cabinets hinges on precise temperature control and consistent steam distribution, ensuring uniform cooking and energy efficiency. Dim sum steaming cabinets typically offer programmable cycles and multi-layer trays that maximize batch capacity while maintaining optimal moisture retention and flavor integrity.

Smart Steam Control Interface

Smart Steam Control Interfaces in steaming cabinets enable precise temperature and humidity adjustments, optimizing cooking conditions for both general steaming and specialized dim sum batch cooking. These interfaces enhance efficiency and consistency by automating steam distribution, reducing energy consumption while maintaining food texture and flavor integrity.

High-Velocity Steam Injection

High-velocity steam injection in steaming cabinets enhances heat distribution and reduces cooking time, making it ideal for batch cooking large quantities efficiently. Compared to traditional dim sum steaming cabinets, these systems deliver more consistent steam penetration, ensuring uniform texture and flavor across diverse dishes.

Steam-Saving Condensation Trays

Steam-saving condensation trays in steaming cabinets reduce water usage by capturing and recycling steam, enhancing energy efficiency during batch cooking compared to traditional dim sum steaming methods. These trays optimize heat distribution and minimize steam loss, making them ideal for consistent, large-scale food preparation.

Menu-Driven Steam Profiling

Menu-driven steam profiling in dim sum steaming cabinets enables precise control over temperature, humidity, and cooking time, ensuring consistent quality and perfect texture for various dim sum items. In contrast, traditional batch steaming lacks this customization, often leading to uneven cooking and reduced efficiency in large-scale food preparation.

Modular Dim Sum Tray Inserts

Modular dim sum tray inserts in steaming cabinets enhance batch cooking efficiency by maximizing steam circulation and allowing customizable portion control. These inserts optimize cooking uniformity and reduce preparation time compared to traditional steaming methods.

Instant-Regen Steam Burst

The Instant-Regen Steam Burst technology in steaming cabinets ensures rapid and consistent steam generation, optimizing heat distribution and reducing cooking time compared to traditional dim sum steaming methods. This innovation enhances batch cooking efficiency by maintaining precise moisture levels, preserving texture and flavor in large volume food preparation.

Steam Loss Reduction Tech

Steaming cabinets designed specifically for dim sum incorporate advanced steam loss reduction technology that preserves moisture and heat efficiency, ensuring consistent cooking results across large batches. Compared to traditional steaming methods, these cabinets minimize steam escape by using sealed chambers and precise pressure control, optimizing energy usage and reducing cooking time.

Steaming vs Dim Sum Steaming Cabinet for batch cooking. Infographic

cookingdiff.com

cookingdiff.com