Wet steaming involves using moisture-laden steam to cook food, which helps retain nutrients and enhances tenderness by preventing drying out. Dry steaming uses steam with minimal moisture, creating a gentler heat that preserves the texture and color of delicate ingredients. Choosing between wet and dry steaming depends on the desired outcome, as wet steaming is ideal for hearty vegetables and meats, while dry steaming suits items requiring a firmer texture.

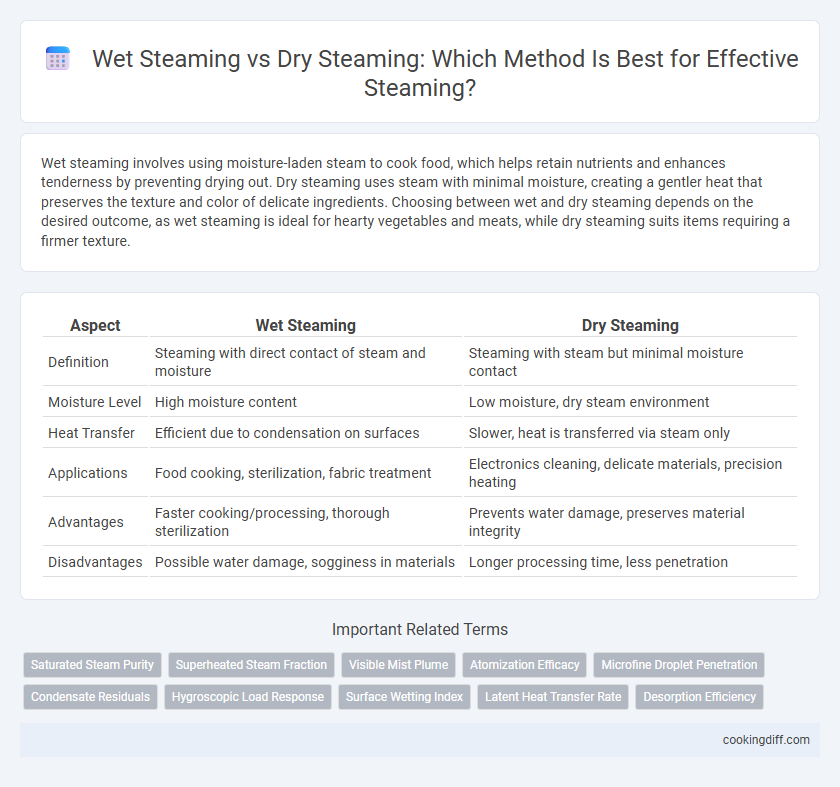

Table of Comparison

| Aspect | Wet Steaming | Dry Steaming |

|---|---|---|

| Definition | Steaming with direct contact of steam and moisture | Steaming with steam but minimal moisture contact |

| Moisture Level | High moisture content | Low moisture, dry steam environment |

| Heat Transfer | Efficient due to condensation on surfaces | Slower, heat is transferred via steam only |

| Applications | Food cooking, sterilization, fabric treatment | Electronics cleaning, delicate materials, precision heating |

| Advantages | Faster cooking/processing, thorough sterilization | Prevents water damage, preserves material integrity |

| Disadvantages | Possible water damage, sogginess in materials | Longer processing time, less penetration |

Introduction to Steaming: Wet vs Dry Methods

Wet steaming involves using water vapor that condenses on the food, providing moisture and helping to retain nutrients and texture. Dry steaming uses heated air or steam without direct water contact, preserving surface crispness and enhancing flavor concentration. Choosing between wet and dry steaming depends on the desired food texture and cooking outcome, with wet steaming favored for vegetables and dry steaming often applied to meats and baked goods.

Defining Wet Steaming and Dry Steaming

What distinguishes wet steaming from dry steaming in culinary applications? Wet steaming involves cooking food with steam generated from boiling water, which keeps the food moist and tender. Dry steaming uses steam produced without direct contact with water, resulting in a firmer texture and concentrated flavors.

Equipment Needed for Wet and Dry Steaming

Wet steaming requires a steam generator or a boiler that produces high-pressure steam, along with a water reservoir to maintain continuous moisture. Equipment often includes steam wands or nozzles designed to disperse water vapor evenly over the surface.

Dry steaming relies on electric or gas steamers that produce low-moisture steam without water droplets, typically featuring specialized heating elements and moisture control systems. These devices are optimized for consistent, dry steam output, minimizing equipment corrosion and enhancing longevity.

How Wet Steaming Works in Cooking

Wet steaming cooks food by surrounding it with steam generated from boiling water, which helps retain moisture and nutrients. This method prevents drying out and offers gentle heat that preserves food texture and flavor.

- Heat Transfer - Steam carries heat efficiently, penetrating food evenly without direct contact with boiling water.

- Moisture Retention - Steam keeps food hydrated, maintaining softness and preventing shrinkage during cooking.

- Nutrient Preservation - The lower temperature in wet steaming reduces nutrient loss compared to high-heat cooking methods.

How Dry Steaming Differs from Traditional Methods

Dry steaming uses minimal or no water, producing steam from heated surfaces or indirect heat sources unlike traditional wet steaming, which relies on boiling water. This method reduces the risk of overhydration and preserves the texture of delicate foods.

- Reduced moisture exposure - Dry steaming limits the food's contact with water vapor, maintaining firmness and nutritional content.

- Lower energy consumption - Without continuous boiling of water, dry steaming often requires less energy than wet steaming methods.

- Enhanced flavor retention - Dry steaming prevents dilution of flavors that can occur when food is steamed over large amounts of water.

Advantages of Wet Steaming for Food Texture

Wet steaming enhances food texture by preserving moisture, which prevents drying and maintains natural juiciness in vegetables and proteins. The steam condenses on the food surface, allowing for gentle cooking that retains tenderness and prevents toughening. This method also helps achieve even heat distribution, ensuring consistent soft and succulent results throughout the dish.

Benefits of Dry Steaming for Flavor Retention

Dry steaming preserves the natural flavors of food by minimizing moisture absorption, which can dilute taste. This method enhances ingredient textures while locking in aromatic compounds.

Compared to wet steaming, dry steaming reduces nutrient loss, keeping vitamins and minerals intact for a healthier meal. It prevents food from becoming soggy, maintaining a desirable consistency and appearance. The technique is especially effective for delicate vegetables and seafood, ensuring robust flavor and optimal culinary results.

Best Foods to Cook with Wet Steaming

Wet steaming is ideal for cooking delicate vegetables like broccoli, asparagus, and spinach, as the moisture helps retain their vibrant color and nutrients. It also works well for seafood such as shrimp and fish fillets, ensuring they stay tender and flavorful without drying out.

Foods with a higher water content, including fruits like apples and pears, benefit from wet steaming, which prevents them from becoming tough or rubbery. Rice and grains absorb the steam evenly, resulting in a fluffy and well-cooked texture, making wet steaming perfect for these staples.

Ideal Ingredients for Dry Steaming

Dry steaming is best suited for ingredients that benefit from minimal moisture exposure, preserving texture and enhancing natural flavors. Foods like vegetables, delicate fish, and certain dim sum varieties retain their structure and nutrients better under dry steam conditions.

- Vegetables - Crisp vegetables such as asparagus and broccoli hold their shape and vibrant color during dry steaming.

- Delicate fish - Fish like sole or cod maintain their flaky texture without becoming soggy when dry steamed.

- Dim sum - Ingredients in dim sum, including dumplings and buns, achieve a tender yet firm consistency under dry steam.

Choosing dry steaming ensures a refined texture and intensified flavor, ideal for delicate and moisture-sensitive foods.

Related Important Terms

Saturated Steam Purity

Wet steaming introduces moisture droplets that can decrease saturated steam purity, causing potential contamination and uneven heat distribution. Dry steaming ensures higher saturated steam purity by maintaining steam in a vapor-only state, enhancing thermal efficiency and preventing equipment corrosion.

Superheated Steam Fraction

Wet steaming utilizes saturated steam containing water droplets, resulting in a lower superheated steam fraction that limits heat transfer efficiency and causes potential moisture-related issues. Dry steaming, with a higher superheated steam fraction, ensures more consistent temperature control and enhanced thermal penetration, optimizing cooking and sterilization processes.

Visible Mist Plume

Wet steaming produces a visible mist plume composed of fine water droplets that enhance heat transfer and surface moisture, making it ideal for delicate fabrics and food steaming. Dry steaming generates minimal visible mist, relying on high-temperature steam vapor that reduces moisture deposition and is preferred for fast drying and sterilization processes.

Atomization Efficacy

Wet steaming enhances atomization efficacy by producing finer steam particles that penetrate surfaces more effectively, leading to improved moisture retention and efficient heat transfer. Dry steaming, while generating less moisture, provides higher temperature steam that may reduce atomization but offers quicker drying and less residue.

Microfine Droplet Penetration

Wet steaming produces microfine droplets that penetrate fabrics more deeply, enhancing moisture absorption and efficient heat transfer. Dry steaming generates vapor with minimal moisture, resulting in less penetration and primarily surface-level treatment.

Condensate Residuals

Wet steaming produces more condensate residuals, which can accumulate and cause water drips or damage sensitive materials, while dry steaming minimizes moisture remnants, ensuring a cleaner steam application with less risk of water-related issues. Controlling condensate buildup in wet steaming requires effective drainage systems to maintain optimal steam quality and prevent operational inefficiencies.

Hygroscopic Load Response

Wet steaming enhances the hygroscopic load response by introducing moisture, which improves heat penetration and accelerates the softening of materials. Dry steaming reduces surface moisture but provides consistent high temperatures, making it effective for materials sensitive to excess water absorption.

Surface Wetting Index

Wet steaming achieves higher Surface Wetting Index values due to increased moisture presence, enhancing surface adhesion and heat transfer efficiency. Dry steaming, while producing less surface wetting, reduces condensation-related issues but may result in lower thermal conductivity and surface contact.

Latent Heat Transfer Rate

Wet steaming delivers a higher latent heat transfer rate due to the direct condensation of saturated steam on the surface, maximizing thermal energy exchange. In contrast, dry steaming involves superheated steam with lower condensation potential, resulting in reduced latent heat transfer efficiency.

Wet Steaming vs Dry Steaming for Steaming Infographic

cookingdiff.com

cookingdiff.com