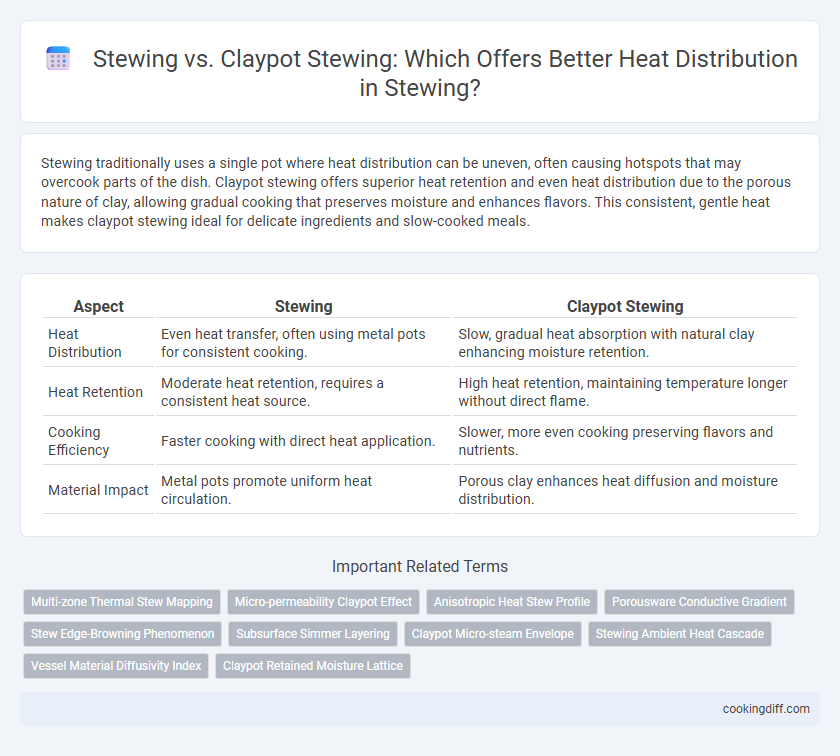

Stewing traditionally uses a single pot where heat distribution can be uneven, often causing hotspots that may overcook parts of the dish. Claypot stewing offers superior heat retention and even heat distribution due to the porous nature of clay, allowing gradual cooking that preserves moisture and enhances flavors. This consistent, gentle heat makes claypot stewing ideal for delicate ingredients and slow-cooked meals.

Table of Comparison

| Aspect | Stewing | Claypot Stewing |

|---|---|---|

| Heat Distribution | Even heat transfer, often using metal pots for consistent cooking. | Slow, gradual heat absorption with natural clay enhancing moisture retention. |

| Heat Retention | Moderate heat retention, requires a consistent heat source. | High heat retention, maintaining temperature longer without direct flame. |

| Cooking Efficiency | Faster cooking with direct heat application. | Slower, more even cooking preserving flavors and nutrients. |

| Material Impact | Metal pots promote uniform heat circulation. | Porous clay enhances heat diffusion and moisture distribution. |

Introduction to Stewing and Claypot Stewing

| Stewing involves slow cooking ingredients in liquid over low heat, ensuring tender textures through even heat distribution inside a heavy pot. Claypot stewing enhances this process by using porous earthenware that retains and distributes heat uniformly, intensifying flavors and maintaining consistent cooking temperatures. The clay material's heat retention and slow release properties make it ideal for dishes requiring gentle simmering and balanced heat dispersion. |

Core Principles of Heat Distribution in Stewing

Stewing relies on even heat distribution through submerged ingredients in liquid, which promotes uniform cooking by gentle simmering. Claypot stewing enhances heat retention and directs heat from the pot's walls, intensifying flavor development and moisture preservation.

- Conduction - Heat transfers from the pot surface directly to the ingredients, ensuring steady cooking in conventional stewing.

- Thermal Mass - Claypots have high thermal mass, maintaining consistent temperature for prolonged periods and preventing hot spots.

- Radiation - Claypot walls radiate heat inward, creating an enveloping effect that deepens flavor and texture complexity.

How Clay Pots Influence Heat Retention

Clay pots excel in heat retention due to their porous structure, which allows for even heat distribution and consistent cooking temperatures. This property ensures that stews simmer gently, preserving flavors and tenderizing ingredients more effectively than metal or glass cookware.

The thick walls of clay pots absorb and radiate heat slowly, preventing sudden temperature fluctuations during stewing. This steady heat retention helps maintain a uniform cooking environment, enhancing the development of rich, well-balanced flavors in the dish.

Metal Pots vs. Claypots: Material Differences

Metal pots conduct heat more efficiently than claypots, providing rapid and even heat distribution essential for consistent stewing. Claypots, made from porous materials, heat slowly and retain heat longer, resulting in a gentler cooking process that enhances flavors over time.

The thermal conductivity of metal pots ensures precise temperature control during stewing, preventing hotspots and burning. Claypots promote moisture retention due to their porous nature, which allows for gradual evaporation and flavor infusion. Choosing between metal and claypots depends on the desired cooking speed and flavor profile in stewing techniques.

Consistency of Temperature in Traditional Stewing

Traditional stewing relies on consistent temperature maintained through slow, even heat application, ensuring tender and flavorful results. Claypot stewing enhances heat distribution by retaining and radiating heat uniformly, reducing hot spots that can cause uneven cooking. This consistent temperature control in claypot stewing preserves moisture and intensifies the depth of flavors compared to conventional methods.

Slow Cooking Benefits in Claypot Stewing

Claypot stewing offers superior heat retention and even heat distribution compared to traditional stewing methods, allowing ingredients to cook slowly and uniformly. This slow cooking process enhances flavor development and tenderizes tougher cuts of meat effectively. The porous nature of claypots also helps to maintain moisture, resulting in richer and more aromatic dishes.

Moisture Management: Claypot vs. Conventional Stewing

Claypot stewing excels in moisture retention due to its porous material, which allows for gradual steam circulation, enhancing flavor infusion. Conventional stewing methods often require more liquid to prevent drying out, potentially diluting taste.

- Claypot's porous structure - Facilitates even steam distribution, preserving moisture and concentrating flavors.

- Heat retention - Claypots maintain consistent low heat, reducing moisture loss during prolonged cooking.

- Conventional pots - Usually metal, can cause evaporation that requires additional liquid input to manage moisture levels.

Flavor Enhancement through Even Heat Dispersion

Stewing relies on consistent heat over a prolonged period, which can sometimes result in uneven heat distribution, potentially affecting flavor extraction. Claypot stewing utilizes the natural properties of clay to disperse heat evenly, enhancing the melding of flavors within the dish.

The porous nature of a claypot allows steam to circulate gently, intensifying the infusion of spices and ingredients. This even heat dispersion promotes a richer, more harmonious blend of flavors compared to traditional stewing methods.

Energy Efficiency: Comparing Stewing Methods

Stewing in a traditional pot often results in uneven heat distribution, leading to hotspots and energy wastage. Claypot stewing provides superior heat retention and uniform cooking, making it more energy-efficient for long, slow cooking processes.

- Heat Retention - Claypots retain heat longer, allowing lower, consistent temperatures that save energy.

- Uniform Cooking - Claypot material distributes heat evenly, preventing energy loss from overheating certain areas.

- Fuel Consumption - Traditional stewing demands higher temperature adjustments, increasing fuel use compared to claypot stewing.

Choosing claypot stewing reduces energy consumption while enhancing cooking quality through stable heat distribution.

Related Important Terms

Multi-zone Thermal Stew Mapping

Multi-zone thermal stew mapping reveals that claypot stewing offers superior heat distribution with evenly calibrated zones, ensuring consistent cooking temperatures throughout the pot. In contrast, traditional stewing methods often result in uneven heat zones, leading to localized hot spots and inconsistent stew texture.

Micro-permeability Claypot Effect

Claypot stewing leverages the micro-permeability of porous clay, allowing steam to circulate evenly and maintain consistent heat distribution, which enhances flavor infusion and tenderness. Stewing in conventional pots lacks this micro-permeable quality, often resulting in less uniform heat transfer and uneven cooking.

Anisotropic Heat Stew Profile

Stewing in traditional pots creates a relatively uniform heat distribution, whereas claypot stewing generates an anisotropic heat stew profile, concentrating heat unevenly due to the clay's porous structure. This anisotropy enhances flavor development by allowing localized high-temperature zones that promote Maillard reactions while preserving moisture in cooler areas.

Porousware Conductive Gradient

Porousware conductive gradient in claypot stewing enables more even heat distribution by slowly absorbing and radiating heat, contrasting with traditional stewing methods where metal pots often create hot spots due to rapid heat conduction. This gradient ensures a consistent temperature throughout the cooking process, enhancing flavor development and preventing uneven cooking typically seen in non-porous cookware.

Stew Edge-Browning Phenomenon

Stewing typically results in uneven heat distribution, causing the stew edge-browning phenomenon where ingredients near the pot's sides overcook and caramelize faster than those in the center. Claypot stewing enhances heat retention and promotes uniform heat dispersion, minimizing edge-browning and ensuring consistent texture and flavor throughout the dish.

Subsurface Simmer Layering

Stewing relies on consistent heat distribution throughout the pot, but claypot stewing excels due to its subsurface simmer layering, where the porous clay material absorbs and radiates heat evenly, creating gradual and uniform cooking temperatures. This natural heat retention in claypots reduces hotspots and maintains steady simmering, enhancing flavor development and tenderizing ingredients more effectively than conventional metal pots.

Claypot Micro-steam Envelope

Claypot stewing utilizes the unique claypot micro-steam envelope that ensures even heat distribution by trapping moisture and circulating steam throughout the pot, resulting in tender, flavorful dishes. This technique contrasts with traditional stewing methods where uneven heat may cause inconsistent cooking and drying out of ingredients.

Stewing Ambient Heat Cascade

Stewing relies on ambient heat cascade, where even heat distribution from the surrounding environment gently breaks down fibers and flavors over time. Claypot stewing enhances this process by providing superior heat retention and gradual heat transfer, ensuring consistent temperature and deeper infusion of ingredients.

Vessel Material Diffusivity Index

Stewing in traditional pots relies on lower Vessel Material Diffusivity Index, often resulting in uneven heat distribution and localized hot spots. Claypot stewing benefits from a higher diffusivity index, allowing more uniform heat transfer and consistent cooking temperatures throughout the vessel.

Stewing vs Claypot Stewing for heat distribution. Infographic

cookingdiff.com

cookingdiff.com