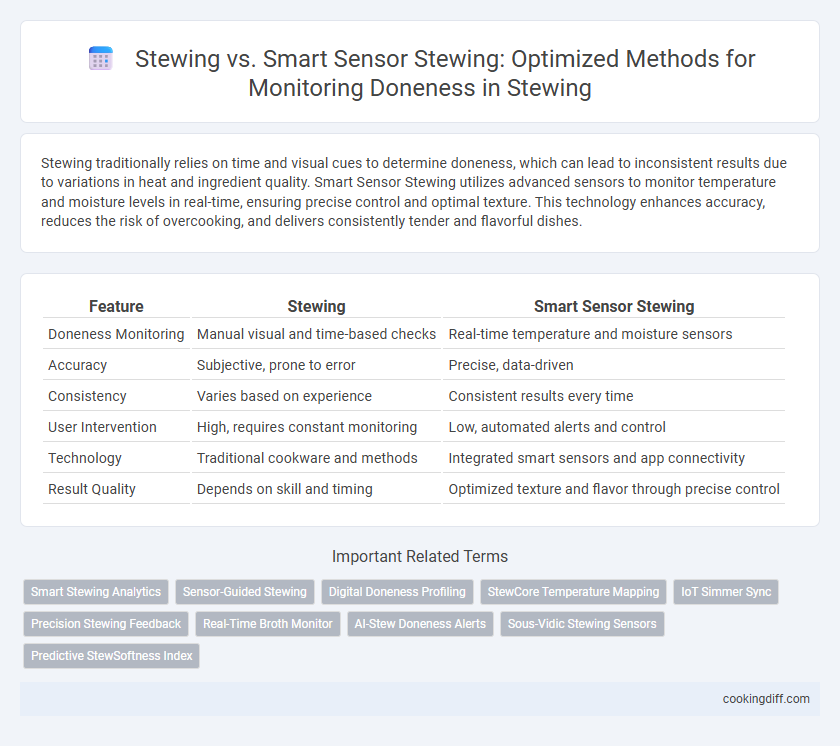

Stewing traditionally relies on time and visual cues to determine doneness, which can lead to inconsistent results due to variations in heat and ingredient quality. Smart Sensor Stewing utilizes advanced sensors to monitor temperature and moisture levels in real-time, ensuring precise control and optimal texture. This technology enhances accuracy, reduces the risk of overcooking, and delivers consistently tender and flavorful dishes.

Table of Comparison

| Feature | Stewing | Smart Sensor Stewing |

|---|---|---|

| Doneness Monitoring | Manual visual and time-based checks | Real-time temperature and moisture sensors |

| Accuracy | Subjective, prone to error | Precise, data-driven |

| Consistency | Varies based on experience | Consistent results every time |

| User Intervention | High, requires constant monitoring | Low, automated alerts and control |

| Technology | Traditional cookware and methods | Integrated smart sensors and app connectivity |

| Result Quality | Depends on skill and timing | Optimized texture and flavor through precise control |

Introduction to Traditional Stewing

Traditional stewing is a slow-cooking method that involves simmering food in liquid at low temperatures to tenderize tough cuts and blend flavors. It requires careful time monitoring to ensure the food reaches optimal doneness without overcooking. This method relies heavily on experience and sensory evaluation rather than precise temperature control.

Understanding the Stewing Process

Stewing involves slow cooking food in liquid to break down tough fibers and develop rich flavors, requiring careful temperature control to ensure proper doneness. Smart Sensor Stewing utilizes advanced temperature and moisture sensors to continuously monitor the cooking process, enhancing precision and consistency compared to traditional methods.

- Stewing Process - It traditionally relies on steady low heat and timing to soften ingredients and meld flavors through prolonged cooking.

- Smart Sensors - These devices provide real-time data on internal temperature and moisture levels, enabling dynamic adjustments during stewing.

- Doneness Monitoring - Sensor technology improves accuracy in achieving optimal texture and safety by preventing overcooking or undercooking.

Challenges in Monitoring Doneness with Conventional Stewing

Conventional stewing methods rely heavily on manual timing and subjective judgment, leading to inconsistent monitoring of doneness. Variations in heat distribution and ingredient density further complicate accurate assessment during stewing.

Without precise feedback, overcooking or undercooking is common, reducing flavor and nutritional value. These challenges emphasize the need for more advanced techniques, such as Smart Sensor Stewing, which offers real-time monitoring for optimal results.

What Is Smart Sensor Stewing?

Smart Sensor Stewing utilizes advanced sensors to continuously monitor the internal temperature and moisture levels of food, ensuring precise doneness without constant checking. This technology offers superior control compared to traditional stewing methods by providing real-time data to optimize cooking results.

- Real-Time Monitoring - Sensors track temperature and moisture inside the pot to prevent overcooking or undercooking.

- Enhanced Precision - Automated adjustments maintain ideal cooking conditions for consistent texture and flavor.

- User Convenience - Alerts and data display reduce the need for manual intervention during the stewing process.

Key Features of Smart Sensor Cooking Technology

Stewing with traditional methods relies on time and temperature control, often requiring manual monitoring to ensure doneness. Smart sensor stewing technology uses integrated sensors to continuously track the internal temperature and moisture levels of the food, providing precision in cooking.

Key features of smart sensor cooking technology include real-time data feedback, automated adjustments of heat to maintain optimal conditions, and alerts when the desired doneness is achieved. This technology enhances consistency by preventing undercooking or overcooking through precise monitoring. Smart sensors reduce the need for guesswork, making stewing more efficient and reliable for perfect results every time.

Comparing Stewing Methods: Precision and Control

| Stewing Method | Precision in Doneness Monitoring | Control Over Cooking Process |

|---|---|---|

| Traditional Stewing | Relies on visual cues and fixed cooking times, often leading to inconsistent doneness levels | Limited control; requires manual adjustments based on experience and observation |

| Smart Sensor Stewing | Utilizes real-time temperature and moisture data to precisely determine optimal doneness | Enhanced control through automated feedback, allowing adjustments to heat and cooking duration for consistent results |

Doneness Detection: Manual vs Smart Sensor Approaches

Manual stewing relies on tactile and visual cues to estimate doneness, often requiring experience to judge when food is fully cooked. This method can lead to inconsistencies due to subjective interpretation and varying cooking conditions.

Smart sensor stewing utilizes advanced temperature and moisture sensors to provide precise, real-time monitoring of doneness. These sensors enable automated control adjustments, ensuring consistent texture and flavor while reducing the risk of undercooking or overcooking.

Advantages of Using Smart Sensors for Stewing

How do smart sensors improve the stewing process compared to traditional methods? Smart sensors provide precise temperature and time monitoring, ensuring consistent doneness and preventing overcooking. They enable real-time adjustments that optimize flavor and texture, enhancing the overall quality of stewed dishes.

Taste and Texture: Stewing Results With and Without Sensors

Stewing without sensors relies on traditional timing and experience, which can result in inconsistent taste and texture due to variations in heat and ingredient quality. Smart sensor stewing continuously monitors internal temperature and moisture, ensuring optimal doneness for tender, flavorful dishes with consistent texture. The use of smart sensors eliminates guesswork, enhancing the overall quality and repeatability of stewed meals.

Related Important Terms

Smart Stewing Analytics

Smart Stewing Analytics leverages advanced sensors and real-time data to precisely monitor doneness by analyzing temperature fluctuations and texture changes during the cooking process. This technology ensures consistent results, reduces overcooking, and enhances flavor by providing accurate feedback compared to traditional stewing methods.

Sensor-Guided Stewing

Sensor-guided stewing utilizes smart sensors to continuously monitor temperature and moisture levels, ensuring precise control over cooking doneness and preventing overcooking. This advanced method enhances consistency and flavor extraction by providing real-time data that traditional stewing methods lack.

Digital Doneness Profiling

Stewing traditionally relies on time and temperature estimates, whereas Smart Sensor Stewing leverages Digital Doneness Profiling to monitor moisture levels, texture changes, and internal temperature in real-time for precise cooking control. This technology enables exact identification of optimal doneness, reducing overcooking and ensuring consistent results.

StewCore Temperature Mapping

StewCore Temperature Mapping provides precise thermal data during both Stewing and Smart Sensor Stewing methods, enabling real-time monitoring to ensure optimal doneness. This technology enhances accuracy in detecting core temperatures, reducing the risk of undercooking and improving food safety standards.

IoT Simmer Sync

IoT Simmer Sync revolutionizes traditional stewing by integrating Smart Sensor Stewing technology, enabling precise monitoring of doneness through real-time temperature and moisture data transmission. This advanced IoT system optimizes cooking times and enhances flavor profiles by adjusting heat levels automatically based on sensor feedback, surpassing conventional stewing accuracy.

Precision Stewing Feedback

Stewing with traditional methods relies on timing and visual cues, which often leads to inconsistent doneness due to variable heat distribution. Smart Sensor Stewing utilizes precise temperature and moisture sensors to provide real-time, accurate feedback, ensuring optimal texture and flavor by monitoring doneness with unmatched precision.

Real-Time Broth Monitor

Stewing traditionally relies on manual observation to determine doneness, which can lead to inconsistent results and overcooking. Smart Sensor Stewing uses a Real-Time Broth Monitor that continuously measures temperature and viscosity, ensuring precise control over flavor extraction and optimal texture throughout the cooking process.

AI-Stew Doneness Alerts

AI-Stew Doneness Alerts leverage advanced smart sensor stewing technology to precisely monitor internal temperatures and moisture levels, ensuring perfectly cooked stews without manual checks. This smart sensor integration surpasses traditional stewing methods by providing real-time alerts that optimize cooking time and prevent overcooking or undercooking.

Sous-Vidic Stewing Sensors

Sous-Vidic stewing sensors utilize precise temperature monitoring and real-time data analysis to ensure optimal doneness, surpassing traditional stewing methods that rely on manual estimation. These smart sensors enable consistent texture and flavor by maintaining precise internal temperatures, reducing the risk of overcooking or undercooking.

Stewing vs Smart Sensor Stewing for monitoring doneness. Infographic

cookingdiff.com

cookingdiff.com