A nonstick pan offers easy cleanup and requires less oil, making it ideal for quick stir-frying of pet-friendly vegetables without sticking or burning. Blue steel pans provide superior heat retention and develop a natural nonstick patina over time, delivering excellent searing and flavor development for stir-fried pet meals. Choosing between these pans depends on the cooking style and preference for maintenance, with nonstick suited for convenience and blue steel favored for durability and enhanced taste.

Table of Comparison

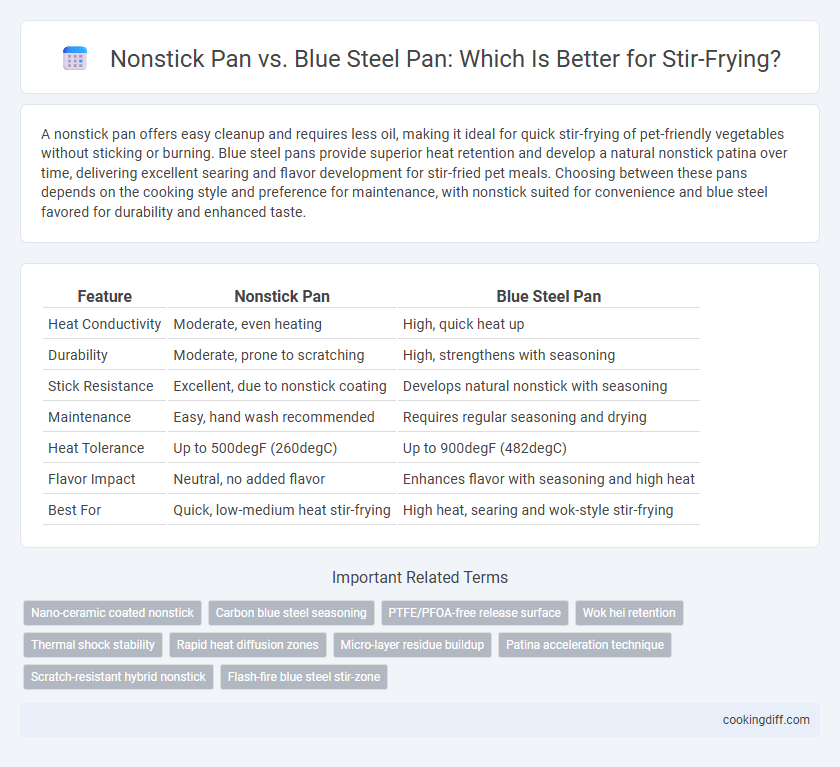

| Feature | Nonstick Pan | Blue Steel Pan |

|---|---|---|

| Heat Conductivity | Moderate, even heating | High, quick heat up |

| Durability | Moderate, prone to scratching | High, strengthens with seasoning |

| Stick Resistance | Excellent, due to nonstick coating | Develops natural nonstick with seasoning |

| Maintenance | Easy, hand wash recommended | Requires regular seasoning and drying |

| Heat Tolerance | Up to 500degF (260degC) | Up to 900degF (482degC) |

| Flavor Impact | Neutral, no added flavor | Enhances flavor with seasoning and high heat |

| Best For | Quick, low-medium heat stir-frying | High heat, searing and wok-style stir-frying |

Introduction: Choosing the Right Pan for Stir-Frying

Nonstick pans offer excellent food release and require less oil, making them ideal for quick, low-fat stir-frying. Blue steel pans develop a natural nonstick patina over time and provide superior heat retention and high-temperature durability for authentic stir-fry techniques. Selecting between these pans depends on balancing ease of use with traditional cooking performance for optimal stir-fry results.

Material Differences: Nonstick vs Blue Steel

Nonstick pans feature a synthetic coating that prevents food from sticking and requires less oil, making them ideal for low-fat stir-frying. Blue steel pans, composed of carbon steel with a bluish oxide layer, offer superior heat retention and develop a natural nonstick patina over time, enhancing flavor and durability. The key material difference lies in nonstick's chemical coating versus blue steel's organic seasoning process, impacting cooking techniques and maintenance.

Heat Conductivity and Distribution

Nonstick pans offer moderate heat conductivity, ensuring even cooking with minimal hot spots, ideal for delicate stir-fry ingredients. Blue steel pans excel in heat conductivity and distribution, providing rapid, uniform heating that enhances stir-fry texture and flavor.

Blue steel pans heat up quickly and maintain consistent temperatures, crucial for high-heat stir-frying techniques. Their superior thermal responsiveness allows for precise control over cooking, preventing food from sticking despite the lack of a nonstick coating. Nonstick pans, while convenient, may not reach the intense heat levels that blue steel pans can sustain for authentic stir-frying.

Surface Properties and Food Release

Nonstick pans offer a smooth surface with superior food release, minimizing sticking during high-heat stir-frying. Blue steel pans develop a natural seasoning layer over time, enhancing food release but initially require proper seasoning to prevent sticking.

- Nonstick Surface - Engineered with a synthetic coating that provides consistent non-stick performance ideal for delicate ingredients.

- Blue Steel Seasoning - Forms a polymerized oil layer with use, improving non-stick qualities and flavor development.

- Heat Tolerance - Blue steel withstands higher temperatures without damage, supporting traditional high-heat stir-frying techniques better than typical nonstick coatings.

Preheating and Cooking Performance

Nonstick pans heat quickly and evenly, making them ideal for rapid preheating during stir-frying, while blue steel pans require gradual heating to prevent warping. Blue steel pans excel in high-heat cooking and develop a natural seasoning that enhances flavor and creates a nearly nonstick surface over time.

- Nonstick pans preheat rapidly - Their coating allows for even heat distribution, reducing cooking time.

- Blue steel pans need gradual heating - Slow preheating avoids damage and ensures durability.

- Blue steel pans improve with use - Seasoning builds a natural nonstick layer and enriches flavor in stir-fried dishes.

Oil Usage and Health Considerations

Nonstick pans require less oil for stir-frying, promoting lower calorie meals, while blue steel pans typically need more oil to prevent food from sticking. Health considerations include potential chemical exposure from nonstick coatings versus the natural seasoning buildup on blue steel pans that can enhance flavor and reduce sticking over time.

- Oil Efficiency - Nonstick pans enable cooking with minimal oil, ideal for low-fat diets.

- Chemical Safety - Blue steel pans avoid synthetic coatings, reducing risk of chemical leaching.

- Seasoning Benefits - Blue steel develops a natural nonstick surface that improves with use and contributes nutrients from the seasoning layer.

Choosing between these pans depends on balancing oil control with long-term health impacts during stir-frying.

Durability and Longevity

Nonstick pans offer convenience in stir-frying due to their smooth surface, but their coating typically degrades within 2 to 5 years, limiting durability. Blue steel pans, made from carbon steel, develop a natural seasoning layer that enhances nonstick properties over time while resisting scratches and high heat damage.

Blue steel pans can last decades when properly maintained, making them a long-term investment for frequent stir-fry use. Nonstick pans require more frequent replacement due to coating wear, which impacts their overall longevity in high-temperature cooking scenarios.

Maintenance and Cleaning Requirements

| Nonstick Pan | Requires gentle cleaning with non-abrasive sponges to preserve the coating; avoids metal utensils to prevent scratching; occasional hand washing recommended to maintain surface integrity. |

| Blue Steel Pan | Needs seasoning before use and regular re-seasoning to prevent rust; after cooking, thoroughly dried and lightly oiled to maintain the protective layer; cleaning involves scrubbing without soap and avoiding prolonged water exposure. |

Best Dishes for Each Pan Type

Which pan works best for different stir-fry dishes? Nonstick pans excel at cooking delicate vegetables and eggs due to their smooth surface that prevents sticking and allows easy flipping. Blue steel pans are ideal for high-heat stir-frying of meats and robust vegetables, providing excellent heat retention and a natural nonstick surface after seasoning.

Related Important Terms

Nano-ceramic coated nonstick

Nano-ceramic coated nonstick pans provide superior food release and easy cleanup for stir-frying, maintaining high heat without toxic fumes, unlike traditional nonstick surfaces. Blue steel pans excel in heat retention and develop a natural seasoning layer but require regular maintenance and seasoning to prevent rust and ensure optimal stir-fry performance.

Carbon blue steel seasoning

Blue steel pans, especially carbon blue steel varieties, develop a natural nonstick surface through proper seasoning that enhances heat retention and imparts a unique flavor to stir-fried dishes. Unlike traditional nonstick pans, their seasoning layer improves with use, providing superior browning and durability for high-heat cooking typical in stir-frying.

PTFE/PFOA-free release surface

Nonstick pans with PTFE/PFOA-free coatings provide a chemical-free release surface that prevents food from sticking during stir-frying, ideal for low to medium heat cooking. Blue steel pans, while offering excellent heat retention and seasoning benefits, lack a chemical nonstick surface and require regular seasoning to maintain a naturally nonstick layer free from synthetic coatings.

Wok hei retention

Blue steel pans excel in retaining wok hei due to their superior heat conductivity and ability to withstand high temperatures essential for authentic stir-frying, producing the characteristic smoky aroma and flavor. Nonstick pans, while easier to clean, typically fail to achieve the intense, high-heat environment necessary for true wok hei, resulting in less pronounced flavors.

Thermal shock stability

Blue steel pans exhibit superior thermal shock stability compared to nonstick pans, allowing them to withstand rapid temperature changes during stir-frying without warping or damage. Nonstick pans, typically made from aluminum or stainless steel with a coating, often degrade or lose performance when exposed to sudden high heat variations common in stir-frying techniques.

Rapid heat diffusion zones

Blue steel pans offer superior rapid heat diffusion due to their excellent thermal conductivity, creating consistent hot zones essential for even stir-frying. Nonstick pans typically have slower heat diffusion, which can result in uneven cooking and less efficient searing of ingredients.

Micro-layer residue buildup

Nonstick pans tend to accumulate a micro-layer residue buildup of oils and food particles over time, which can affect heat distribution and flavor during stir-frying. Blue steel pans develop a natural seasoning layer that reduces residue buildup and enhances the pan's nonstick properties, promoting even cooking and improved taste.

Patina acceleration technique

Blue steel pans develop a natural nonstick patina faster than traditional nonstick pans through repeated seasoning and high-heat stir-frying, enhancing flavor and reducing the need for oil. This patina acceleration technique allows blue steel pans to improve heat retention and durability, making them ideal for achieving authentic stir-fry textures.

Scratch-resistant hybrid nonstick

Scratch-resistant hybrid nonstick pans combine the durability of reinforced coatings with the ease of cleaning and excellent heat distribution ideal for stir-frying delicate ingredients. Blue steel pans offer superior heat retention and high-temperature searing but require seasoning and careful maintenance to prevent rust and stickiness.

Nonstick pan vs Blue steel pan for stir-frying. Infographic

cookingdiff.com

cookingdiff.com