When preparing ingredients for stir-frying, the choice between a plastic cutting board and a composite cutting board impacts both durability and food safety. Plastic cutting boards are lightweight, easy to sanitize, and resist staining, making them ideal for cutting meats and vegetables quickly before cooking. Composite cutting boards offer superior knife edge retention and are more resistant to deep grooves, reducing the risk of bacterial contamination during intensive stir-fry prep.

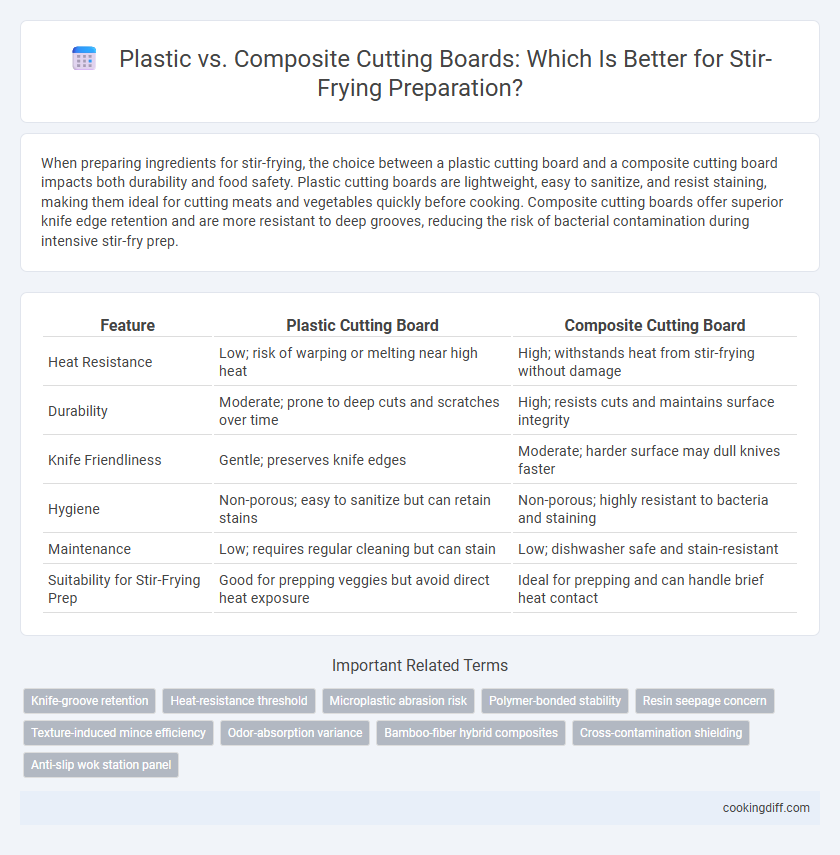

Table of Comparison

| Feature | Plastic Cutting Board | Composite Cutting Board |

|---|---|---|

| Heat Resistance | Low; risk of warping or melting near high heat | High; withstands heat from stir-frying without damage |

| Durability | Moderate; prone to deep cuts and scratches over time | High; resists cuts and maintains surface integrity |

| Knife Friendliness | Gentle; preserves knife edges | Moderate; harder surface may dull knives faster |

| Hygiene | Non-porous; easy to sanitize but can retain stains | Non-porous; highly resistant to bacteria and staining |

| Maintenance | Low; requires regular cleaning but can stain | Low; dishwasher safe and stain-resistant |

| Suitability for Stir-Frying Prep | Good for prepping veggies but avoid direct heat exposure | Ideal for prepping and can handle brief heat contact |

Introduction: Choosing the Right Cutting Board for Stir-Frying

| Plastic cutting boards offer a non-porous surface that resists moisture and bacteria, making them a hygienic option for prepping vegetables and meats used in stir-frying. |

| Composite cutting boards, made from pressed wood fibers and resin, provide durability and knife-friendliness, reducing blade dulling during frequent chopping and slicing. |

| Choosing between plastic and composite boards depends on balancing hygiene needs with cutting performance and maintenance preferences for stir-fry ingredient preparation. |

Material Overview: Plastic vs Composite Cutting Boards

Plastic cutting boards are typically made from high-density polyethylene (HDPE), offering a non-porous surface that resists bacteria and is dishwasher safe, making them suitable for handling raw ingredients in stir-frying. Composite cutting boards combine wood fibers with resin, creating a durable, knife-friendly surface that resists warping and is less prone to deep scratches that can harbor bacteria. Both materials provide hygienic options, but plastic excels in easy sanitation while composite boards offer enhanced longevity and a natural feel.

Safety and Hygiene Concerns in Stir-Frying Preparation

Plastic cutting boards are non-porous and easier to sanitize, reducing the risk of bacterial contamination during stir-frying preparation. Composite cutting boards offer durability and resistance to deep grooves, which helps maintain hygiene by preventing food particles from harboring bacteria.

- Plastic cutting boards resist moisture - This limits bacterial growth and cross-contamination in stir-fry ingredient prep.

- Composite boards have antimicrobial properties - These properties further inhibit bacterial development on the surface.

- Both materials withstand dishwasher cleaning - Ensures thorough sanitation essential for safe stir-frying preparation.

Choosing the right cutting board enhances food safety and hygiene for optimal stir-frying results.

Knife-Friendly Surfaces: Protecting Your Blades

Plastic cutting boards offer softer surfaces that reduce blade dulling, making them ideal for frequent stir-fry prep. Composite cutting boards balance durability with gentler knife impact, preserving sharp edges longer during intensive chopping tasks.

- Plastic cutting boards are gentle on knives - Their non-abrasive surface minimizes blade wear compared to harder materials.

- Composite cutting boards enhance durability - Made from resin-infused wood fibers, they withstand heavy chopping without significant knife damage.

- Both options reduce blade dulling risks - Choosing these boards helps maintain sharpness essential for precise stir-frying cuts.

Durability and Lifespan Comparison

Composite cutting boards generally offer greater durability and a longer lifespan compared to plastic cutting boards due to their resistant materials and construction. Stir-frying preparations benefit from composite boards as they withstand frequent chopping without significant wear.

- Durability - Composite boards resist scratches and heat damage better than plastic boards.

- Lifespan - Composite boards maintain structural integrity longer with regular use.

- Maintenance - Plastic boards may show deeper cuts leading to faster degradation and potential bacterial buildup.

Maintenance and Cleaning Tips

Plastic cutting boards are non-porous, making them easier to sanitize after preparing ingredients for stir-frying; they can be safely cleaned in a dishwasher to eliminate bacteria. Composite cutting boards, made from a mix of wood fibers and resin, require hand washing with hot, soapy water and should be dried immediately to prevent warping and bacteria growth.

Regular maintenance of plastic boards involves inspecting for deep grooves where bacteria can hide, replacing them when heavily scored. Composite boards benefit from occasional oiling with mineral oil to maintain their integrity and prevent cracking, ensuring a longer lifespan for stir-frying preparation tasks.

Heat and Chemical Resistance During Prep

Plastic cutting boards offer moderate heat resistance but can warp or release chemicals when exposed to high temperatures typical in stir-frying prep. Composite cutting boards, made from resin-infused wood fibers, provide superior heat resistance and do not leach harmful substances. Choosing a composite board ensures safer and more durable prep surfaces when handling hot ingredients during stir-frying.

Grip and Stability on the Counter

Which cutting board offers better grip and stability on the counter for stir-frying preparation? Plastic cutting boards often feature textured, non-slip surfaces that enhance grip and prevent sliding during vigorous chopping. Composite cutting boards combine resin and natural fibers, providing a heavier, more stable base that resists movement effectively, making them ideal for precise stir-fry ingredient prep.

Environmental Impact: Sustainability and Disposal

Plastic cutting boards contribute to environmental pollution due to their non-biodegradable nature and reliance on petroleum-based materials, posing challenges in sustainability and waste management. Composite cutting boards, made from a blend of wood fibers and resin, offer a more eco-friendly alternative by utilizing renewable resources and often being recyclable or biodegradable.

Disposal of plastic cutting boards typically results in long-term landfill accumulation and microplastic contamination, whereas composite boards degrade more efficiently and have a lower carbon footprint throughout their lifecycle. Choosing composite cutting boards supports sustainable kitchen practices by reducing environmental impact and promoting responsible material use.

Related Important Terms

Knife-groove retention

Plastic cutting boards exhibit superior knife-groove retention for stir-frying preparation, maintaining a smoother surface that prevents bacterial buildup and extends blade sharpness. Composite cutting boards, while durable and heat-resistant, tend to develop deeper grooves faster, potentially harboring more contaminants and compromising food safety over time.

Heat-resistance threshold

Plastic cutting boards typically have a lower heat-resistance threshold, melting or warping at temperatures above 120degC (248degF), which poses a risk during stir-frying preparations involving high heat. Composite cutting boards, made from resin and wood fibers, endure higher temperatures up to 150degC (302degF) without damage, making them better suited for handling ingredients near hot stir-fry pans.

Microplastic abrasion risk

Plastic cutting boards pose a higher risk of microplastic abrasion during stir-frying preparation due to their softer material, which can break down with repeated knife use. Composite cutting boards, made from denser, reinforced materials, offer greater durability and reduce the likelihood of microplastic contamination in stir-fried dishes.

Polymer-bonded stability

Polymer-bonded stability in composite cutting boards offers superior resistance to heat and knife stress compared to plastic cutting boards, making them more durable and less prone to warping during stir-frying preparation. Composite boards provide a stable, non-porous surface that reduces cross-contamination risk and maintains structural integrity under high-temperature cooking conditions.

Resin seepage concern

Plastic cutting boards can sometimes release resin or plastic particles when exposed to high heat or prolonged knife impact, posing a contamination risk for stir-frying ingredients. Composite cutting boards, made from resin-infused wood fibers, offer enhanced durability and reduced resin seepage, making them safer and more reliable for prepping stir-fry vegetables and meats.

Texture-induced mince efficiency

Plastic cutting boards offer a smooth, non-porous surface that allows for consistent, easy mincing of ingredients needed for stir-frying, reducing blade wear and preventing contamination. Composite cutting boards feature a slightly textured surface that improves grip on ingredients, enhancing control and precision during mincing but may cause marginally more resistance on knives compared to plastic.

Odor-absorption variance

Plastic cutting boards tend to absorb fewer odors compared to composite cutting boards, making them more suitable for stir-frying preparations that involve aromatic ingredients. Composite cutting boards can retain strong smells from spices and sauces, potentially affecting the flavor profile of stir-fried dishes.

Bamboo-fiber hybrid composites

Bamboo-fiber hybrid composite cutting boards offer superior durability and heat resistance compared to standard plastic boards, making them ideal for the quick, high-heat demands of stir-frying preparation. Their natural antimicrobial properties and eco-friendly composition provide a safer, more sustainable option while maintaining a knife-friendly surface that reduces blade wear.

Cross-contamination shielding

Plastic cutting boards offer superior resistance to cross-contamination during stir-frying preparation due to their non-porous surface, which prevents bacteria absorption and allows for easy sanitization. In contrast, composite cutting boards, while durable, may have microscopic crevices that can harbor bacteria, increasing the risk of cross-contamination if not cleaned thoroughly.

Plastic cutting board vs Composite cutting board for stir-frying. Infographic

cookingdiff.com

cookingdiff.com