Carbon steel woks heat up quickly and distribute heat evenly, making them ideal for high-heat stir-frying and achieving that perfect sear on pet ingredients. Steel woks, often stainless steel, are more durable and resistant to rust but may not retain heat as efficiently, potentially leading to uneven cooking. For optimal stir-frying results with pet dishes, carbon steel woks offer superior heat responsiveness and a non-stick seasoning surface that enhances flavor.

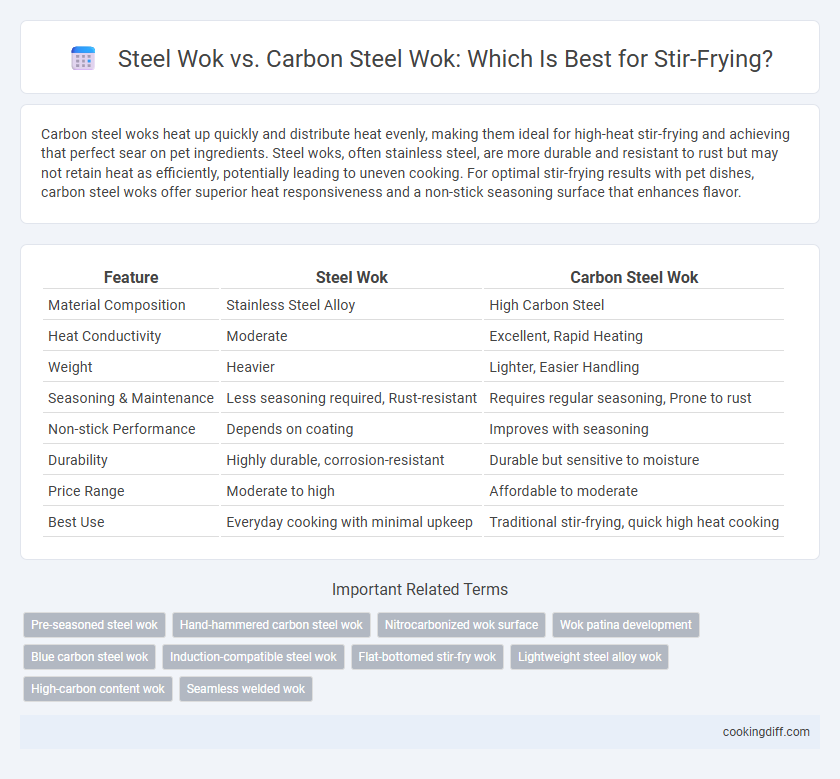

Table of Comparison

| Feature | Steel Wok | Carbon Steel Wok |

|---|---|---|

| Material Composition | Stainless Steel Alloy | High Carbon Steel |

| Heat Conductivity | Moderate | Excellent, Rapid Heating |

| Weight | Heavier | Lighter, Easier Handling |

| Seasoning & Maintenance | Less seasoning required, Rust-resistant | Requires regular seasoning, Prone to rust |

| Non-stick Performance | Depends on coating | Improves with seasoning |

| Durability | Highly durable, corrosion-resistant | Durable but sensitive to moisture |

| Price Range | Moderate to high | Affordable to moderate |

| Best Use | Everyday cooking with minimal upkeep | Traditional stir-frying, quick high heat cooking |

Introduction: Why the Right Wok Matters for Stir-Frying

Choosing the right wok is essential for achieving authentic stir-fry flavors and optimal cooking performance. Steel woks offer superior durability and resistance to warping, making them ideal for high-heat cooking.

Carbon steel woks heat quickly and evenly, enhancing the wok hei effect crucial for stir-frying. Proper seasoning and maintenance of carbon steel woks ensure a natural non-stick surface for consistent results.

What Is a Steel Wok?

A steel wok is typically made from non-coated stainless steel, offering durability and resistance to rust but lacking the heat retention qualities of carbon steel. It is less reactive to acidic ingredients, making it suitable for cooking a variety of dishes without imparting metallic flavors.

- Durability - Steel woks are more resistant to corrosion and scratching compared to carbon steel woks.

- Heat retention - They generally have lower heat retention, which can affect stir-frying efficiency.

- Maintenance - Steel woks require less seasoning and are easier to clean but may not develop a natural non-stick surface like carbon steel.

Understanding Carbon Steel Woks

Carbon steel woks are favored for stir-frying due to their excellent heat retention and responsiveness, which are superior to most stainless steel woks. They develop a natural non-stick patina over time, enhancing flavor and cooking performance with regular use.

- Heat Conductivity - Carbon steel heats evenly and quickly, making it ideal for high-heat stir-frying.

- Durability - It balances strength and lightness, resisting warping under intense cooking conditions.

- Seasoning - Proper seasoning creates a non-stick surface, improving taste and ease of cooking.

Key Differences: Steel Wok vs Carbon Steel Wok

Carbon steel woks heat up faster and offer superior heat retention, making them ideal for high-temperature stir-frying techniques. Steel woks, often stainless steel, are more durable and resistant to rust but may have uneven heat distribution compared to carbon steel. The lightweight nature of carbon steel woks also allows for easier tossing and stirring of ingredients during cooking.

Heat Conductivity and Stir-Frying Performance

Which wok material offers better heat conductivity for stir-frying: steel or carbon steel?

Carbon steel woks provide superior heat conductivity, allowing for rapid and even heating essential for high-heat stir-frying techniques. Steel woks, while durable, tend to heat unevenly and do not retain high temperatures as effectively, which can impact the stir-frying performance.

Nonstick Qualities: Seasoning and Patina Formation

Carbon steel woks develop a superior nonstick surface through seasoning and patina formation, enhancing stir-frying efficiency over time. Steel woks require more maintenance to achieve and maintain a comparable nonstick quality.

- Carbon steel seasoning - Forms a natural, chemical-resistant patina that improves with use, reducing food sticking.

- Steel wok maintenance - Requires frequent re-seasoning to prevent rust and maintain some nonstick properties.

- Patina durability - Carbon steel's patina is more durable and effective for high-heat stir-frying techniques.

Carbon steel woks are preferred by chefs for their evolving nonstick qualities that enhance stir-frying performance over time.

Durability and Longevity in the Kitchen

Steel woks, especially those made from stainless steel, offer superior resistance to rust and corrosion, making them highly durable for long-term kitchen use. Carbon steel woks require regular seasoning and proper care to prevent rust, but they develop a natural non-stick patina that enhances cooking performance over time.

In terms of longevity, carbon steel woks can last for decades if properly maintained, as their material is both lightweight and strong. Steel woks tend to be more resistant to dents and deformation, making them suitable for heavy-duty stir-frying. Both materials provide excellent durability, but carbon steel's need for upkeep means its lifespan depends heavily on user care and seasoning practices.

Ease of Cleaning and Maintenance

Carbon steel woks require regular seasoning to maintain their non-stick surface and prevent rust, making cleaning and maintenance more involved compared to steel woks. Steel woks, often coated or stainless, are generally easier to clean due to their resistance to rust and lower maintenance needs. For frequent stir-frying, users seeking hassle-free upkeep may prefer steel woks, while carbon steel offers superior heat responsiveness at the cost of more diligent maintenance.

Price Comparison: Which Offers Better Value?

Carbon steel woks generally offer better value for stir-frying due to their lower price and excellent heat conductivity, allowing for quick, even cooking. Steel woks, often stainless steel, tend to be pricier and may not heat as uniformly, which can affect stir-fry quality.

While carbon steel requires seasoning and careful maintenance to prevent rust, its affordability and superior cooking performance make it a top choice for many chefs. Steel woks' durability and ease of cleaning come at a higher cost, which might not justify the investment for everyday stir-fry cooking.

Related Important Terms

Pre-seasoned steel wok

Pre-seasoned carbon steel woks offer superior heat retention and faster heat-up times compared to steel woks, making them ideal for authentic stir-frying techniques that require high temperatures. The natural non-stick surface developed through seasoning enhances flavor development and reduces the need for excess oil, improving both cooking efficiency and food quality.

Hand-hammered carbon steel wok

Hand-hammered carbon steel woks excel in stir-frying due to their superior heat retention and quick responsiveness, creating an ideal high-heat cooking surface that evenly sears ingredients while preserving flavor. Unlike steel woks that may lack heat control precision, carbon steel woks develop a natural non-stick seasoning over time, enhancing food release and durability for professional-quality stir-fry results.

Nitrocarbonized wok surface

A nitrocarbonized steel wok surface significantly enhances durability and corrosion resistance compared to traditional carbon steel woks, maintaining superior heat retention and achieving optimal non-stick properties for rapid stir-frying. The nitrocarbonization process forms a dense, hard layer that improves wok longevity while ensuring even heat distribution crucial for high-temperature cooking techniques.

Wok patina development

Carbon steel woks develop a naturally non-stick patina over time through seasoning, enhancing flavor and improving stir-frying performance by preventing food from sticking. Steel woks, often stainless, resist rust but lack the same patina development, resulting in less efficient seasoning and a different cooking surface texture.

Blue carbon steel wok

Blue carbon steel woks offer superior heat retention and quicker responsiveness to temperature changes compared to stainless steel or regular carbon steel woks, making them ideal for high-heat stir-frying techniques. Their natural non-stick patina develops over time, enhancing flavor and reducing the need for excessive oil, which is essential for achieving authentic stir-fry results.

Induction-compatible steel wok

Carbon steel woks are preferred for stir-frying due to their superior heat retention, lightweight nature, and quick heat responsiveness, making them ideal for high-temperature cooking on induction-compatible steel woks. Steel woks designed for induction cooking often feature flat bottoms and magnetic properties, ensuring efficient heat transfer and even cooking performance on induction stoves.

Flat-bottomed stir-fry wok

Flat-bottomed carbon steel woks offer superior thermal conductivity and faster heat-up times compared to steel woks, making them ideal for high-heat stir-frying techniques. Their lightweight design and excellent heat retention enable even cooking and a perfect sear, essential for authentic stir-fry texture and flavor.

Lightweight steel alloy wok

Lightweight steel alloy woks offer quicker heat conduction and easier maneuverability compared to traditional carbon steel woks, making them ideal for rapid stir-frying techniques. Their corrosion resistance and reduced maintenance needs enhance durability while maintaining the essential high-heat tolerance required for authentic stir-fry cooking.

High-carbon content wok

High-carbon steel woks offer superior heat retention and faster heating compared to steel woks, making them ideal for high-temperature stir-frying techniques. Their excellent durability and natural non-stick seasoning develop over time, enhancing flavor and preventing food from sticking during rapid, high-heat cooking.

Steel wok vs Carbon steel wok for stir-frying Infographic

cookingdiff.com

cookingdiff.com