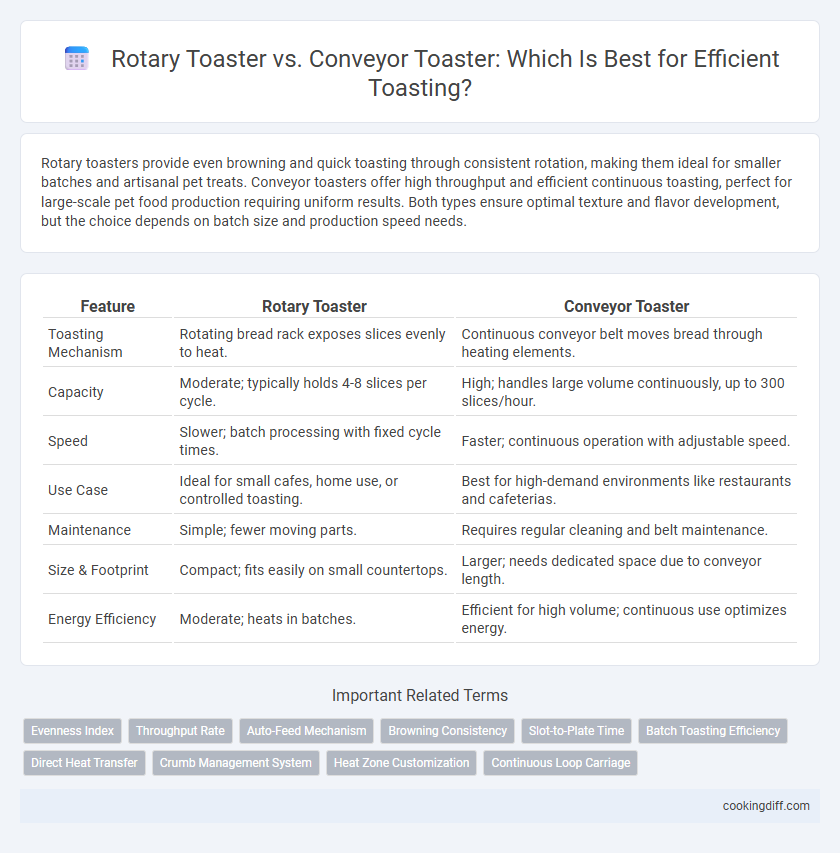

Rotary toasters provide even browning and quick toasting through consistent rotation, making them ideal for smaller batches and artisanal pet treats. Conveyor toasters offer high throughput and efficient continuous toasting, perfect for large-scale pet food production requiring uniform results. Both types ensure optimal texture and flavor development, but the choice depends on batch size and production speed needs.

Table of Comparison

| Feature | Rotary Toaster | Conveyor Toaster |

|---|---|---|

| Toasting Mechanism | Rotating bread rack exposes slices evenly to heat. | Continuous conveyor belt moves bread through heating elements. |

| Capacity | Moderate; typically holds 4-8 slices per cycle. | High; handles large volume continuously, up to 300 slices/hour. |

| Speed | Slower; batch processing with fixed cycle times. | Faster; continuous operation with adjustable speed. |

| Use Case | Ideal for small cafes, home use, or controlled toasting. | Best for high-demand environments like restaurants and cafeterias. |

| Maintenance | Simple; fewer moving parts. | Requires regular cleaning and belt maintenance. |

| Size & Footprint | Compact; fits easily on small countertops. | Larger; needs dedicated space due to conveyor length. |

| Energy Efficiency | Moderate; heats in batches. | Efficient for high volume; continuous use optimizes energy. |

Overview: Rotary Toaster vs Conveyor Toaster

Rotary toasters use spinning racks to evenly toast a batch of bread slices simultaneously, offering a consistent golden-brown result. Conveyor toasters, featuring a continuous belt system, provide high-speed toasting ideal for large volume operations.

- Rotary Toaster Efficiency - Suitable for moderate throughput, ensuring even heat distribution with minimal monitoring.

- Conveyor Toaster Speed - Delivers rapid toasting for continuous output, accommodating high-demand environments.

- Maintenance and Operation - Rotary toasters require less frequent cleaning compared to conveyor models due to simpler mechanics.

Choosing between rotary and conveyor toasters depends on the volume and speed requirements of your toasting needs.

How Rotary Toasters Work

Rotary toasters use a motorized belt that continuously moves bread through a heated chamber, ensuring even browning on all sides. The rotating action prevents burning by evenly exposing the bread to infrared heating elements.

Unlike conveyor toasters that rely on a constant linear feed, rotary toasters offer precise control over toasting time and temperature. This mechanism is ideal for achieving uniform texture and color, especially in high-volume settings.

How Conveyor Toasters Operate

Conveyor toasters operate by continuously moving bread slices on a conveyor belt through a heating chamber. This mechanism ensures consistent toasting, making them ideal for high-volume environments like restaurants and cafeterias.

Inside the conveyor toaster, adjustable heating elements emit infrared or radiant heat to toast the bread evenly as it passes through. Operators can control the speed of the conveyor belt, which directly affects the browning level and cooking time. This system allows for rapid, uniform toasting of multiple slices without the need for manual intervention.

Toasting Speed & Efficiency Comparison

Which toaster offers faster toasting and higher efficiency, a rotary toaster or a conveyor toaster? Conveyor toasters excel in toasting speed with continuous bread feeding, ideal for high-volume settings, producing up to 240 slices per hour. Rotary toasters provide moderate speed but are more energy-efficient, perfect for small-scale operations requiring consistent, even toasting.

Toast Quality and Consistency

Rotary toasters provide even toasting by continuously rotating bread slices around a heat source, ensuring uniform exposure to heat and preventing hotspots that cause uneven browning. This mechanism results in consistent toast quality suitable for high-volume settings requiring precise color control.

Conveyor toasters utilize a moving belt system that transports bread through a stationary heating chamber, offering adjustable speed controls to customize toasting time and intensity. Their design supports rapid throughput but may produce variability in toast consistency depending on bread placement and belt speed settings.

Capacity: Batch Size & Throughput

Rotary toasters typically offer smaller batch sizes with even toasting, suitable for moderate volume needs. Conveyor toasters handle higher throughput with continuous operation, ideal for large-scale foodservice environments.

- Rotary Toaster Batch Size - Usually accommodates 4 to 6 slices per cycle, offering precise control over each batch.

- Conveyor Toaster Throughput - Capable of toasting up to 250 slices per hour, boosting operational efficiency.

- Operational Capacity - Conveyor systems support nonstop toasting, whereas rotary toasters require loading between batches.

Energy Consumption & Cost-Effectiveness

Rotary toasters generally consume less energy due to their compact design and efficient toasting mechanism, making them more cost-effective for small to medium-sized operations. Conveyor toasters require higher energy input as they continuously run to handle large volumes, which increases operational costs but suits high-demand environments. Choosing between the two depends on balancing energy consumption with toasting volume for optimal cost-efficiency.

Durability and Maintenance Requirements

Rotary toasters typically feature robust construction with fewer moving parts, resulting in enhanced durability and lower maintenance needs compared to conveyor toasters. Conveyor toasters, while efficient for high-volume tasks, require more frequent cleaning and maintenance to prevent conveyor belt wear and mechanical issues.

- Rotary toasters have sturdy designs - Their simpler mechanisms reduce the frequency of breakdowns and extend operational lifespan.

- Conveyor toasters demand regular maintenance - Conveyor belts and moving components need routine inspection and cleaning to avoid malfunctions.

- Rotary toasters minimize maintenance costs - Limited parts and easy access for cleaning decrease downtime and repair expenses.

Best Applications for Rotary Toasters

Rotary toasters excel in high-volume environments requiring consistent, evenly toasted bread slices, making them ideal for hotels and large cafeterias. Their rotating mechanism ensures uniform heat distribution and reduces the risk of burning, perfect for delicate breads and pastries. These toasters are best suited for operations needing quick, repeatable results with minimal manual intervention.

Related Important Terms

Evenness Index

The Rotary toaster typically achieves a higher Evenness Index compared to conveyor toasters, ensuring uniformly toasted bread with consistent heat distribution across all slices. Conveyor toasters may produce variable results, as uneven belt speed and heat zones can cause sporadic browning, reducing the overall toasting uniformity.

Throughput Rate

Rotary toasters typically offer a throughput rate of 1,200 to 1,800 slices per hour, ideal for moderate volume operations, while conveyor toasters can achieve up to 4,000 slices per hour, making them more suitable for high-demand environments. The continuous feed mechanism in conveyor toasters ensures faster and more consistent toasting compared to the batch process of rotary toasters.

Auto-Feed Mechanism

Rotary toasters with auto-feed mechanisms provide precise, consistent toasting by gently rotating bread through heated elements, ensuring uniform browning and reduced manual handling. Conveyor toasters feature continuous belts that automatically transport bread slices at adjustable speeds, offering high-volume capacity ideal for busy commercial kitchens.

Browning Consistency

Rotary toasters provide superior browning consistency by evenly rotating bread slices, ensuring uniform heat exposure across surfaces. Conveyor toasters may produce uneven toasting due to variable conveyor speeds and uneven heat distribution, leading to inconsistent browning results.

Slot-to-Plate Time

Rotary toasters typically offer faster slot-to-plate time compared to conveyor toasters, making them ideal for quick, high-volume toasting where speed is crucial. Conveyor toasters provide consistent, evenly toasted bread but generally require a longer slot-to-plate time due to their continuous feed design.

Batch Toasting Efficiency

Rotary toasters excel in batch toasting efficiency by evenly and simultaneously browning multiple slices with uniform heat distribution, reducing cook time per batch. Conveyor toasters offer continuous throughput ideal for high-volume environments but may require longer toasting times per slice due to incremental heat exposure.

Direct Heat Transfer

Rotary toasters utilize rotating racks that provide uniform direct heat transfer by continuously turning bread slices within the heating chamber, ensuring even toasting on all sides. Conveyor toasters rely on a moving belt system where bread passes through fixed heating elements, offering consistent direct heat transfer but potentially less uniformity compared to the rotary design.

Crumb Management System

Rotary toasters feature an integrated Crumb Management System that collects and disposes of crumbs efficiently, reducing maintenance and preventing buildup within the machine. Conveyor toasters typically lack advanced crumb management, requiring frequent manual cleaning to avoid crumb accumulation and potential fire hazards.

Heat Zone Customization

Rotary toasters offer precise heat zone customization by allowing separate control of multiple heating elements, ensuring even toasting for different bread types simultaneously. Conveyor toasters typically have fixed heat zones, limiting flexibility in adjusting temperature for varying toasting preferences.

Rotary toaster vs conveyor toaster for toasting. Infographic

cookingdiff.com

cookingdiff.com