Toasting enhances snack flavor and texture by applying dry heat, creating a crunchy surface and caramelized taste, whereas freeze-drying preserves nutrients and natural flavors through low-temperature dehydration. Toasted snacks often have a richer aroma and crispiness, ideal for immediate consumption, while freeze-dried snacks offer a lightweight, long shelf life suitable for storage and portability. Choosing between toasting and freeze-drying depends on the desired snack characteristics, balancing taste, texture, and preservation needs.

Table of Comparison

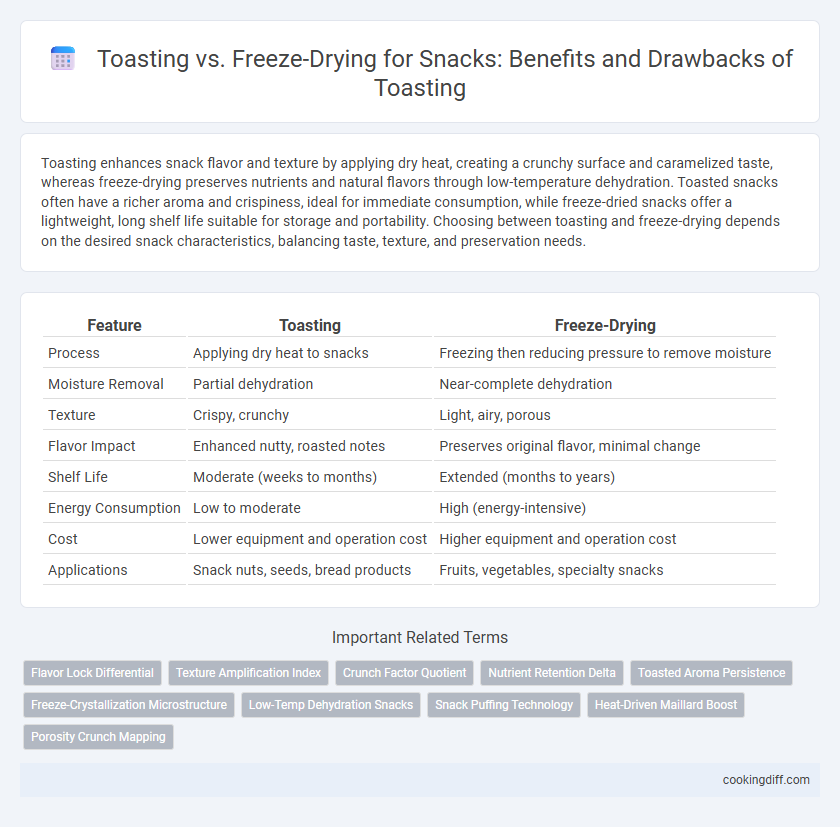

| Feature | Toasting | Freeze-Drying |

|---|---|---|

| Process | Applying dry heat to snacks | Freezing then reducing pressure to remove moisture |

| Moisture Removal | Partial dehydration | Near-complete dehydration |

| Texture | Crispy, crunchy | Light, airy, porous |

| Flavor Impact | Enhanced nutty, roasted notes | Preserves original flavor, minimal change |

| Shelf Life | Moderate (weeks to months) | Extended (months to years) |

| Energy Consumption | Low to moderate | High (energy-intensive) |

| Cost | Lower equipment and operation cost | Higher equipment and operation cost |

| Applications | Snack nuts, seeds, bread products | Fruits, vegetables, specialty snacks |

Introduction to Snack Preservation Methods

What are the key differences between toasting and freeze-drying for snack preservation? Toasting uses heat to remove moisture, enhancing flavor and creating a crispy texture, while freeze-drying removes moisture through sublimation, preserving nutrients and extending shelf life. Both methods improve snack stability but impact texture and nutritional value differently.

What is Toasting?

Toasting is a dry heat cooking method used to enhance the flavor and texture of snacks by applying direct heat. Unlike freeze-drying, toasting results in a crunchy exterior while maintaining some moisture inside.

- Heat Application - Toasting uses direct dry heat to brown and crisp the surface of the snack.

- Flavor Development - The Maillard reaction during toasting intensifies flavors, adding a roasted taste.

- Texture Changes - Toasting creates a crunchy, slightly crispy texture without fully dehydrating the snack.

What is Freeze-Drying?

| Freeze-Drying Definition | Freeze-drying, or lyophilization, removes moisture from snacks by freezing them and then reducing surrounding pressure to allow ice to sublimate directly into vapor, preserving texture and nutrients. |

| Advantages | Maintains original flavor, extends shelf life significantly, and retains more vitamins and antioxidants compared to traditional drying methods. |

| Applications | Commonly used for fruits, vegetables, and protein snacks where maintaining structural integrity and nutritional value is critical. |

Key Differences: Toasting vs Freeze-Drying

Toasting involves applying dry heat to snacks, enhancing flavor and texture by creating a crunchy exterior, while freeze-drying removes moisture through sublimation, preserving nutrients and extending shelf life without altering shape. Toasted snacks typically have a richer, roasted taste, whereas freeze-dried snacks retain original flavors with a light, airy consistency.

Freeze-drying is ideal for preserving delicate ingredients, maintaining maximum nutritional value, and offering long-term storage benefits. Toasting accelerates cooking time and provides immediate textural contrast but may reduce some heat-sensitive nutrients. Both methods are popular in snack production, chosen based on desired taste, texture, and shelf stability.

Flavor Impact: Toasting and Freeze-Drying

Toasting enhances snack flavor by generating Maillard reactions, resulting in a rich, caramelized taste and a crunchy texture that appeals to the palate. Freeze-drying preserves the original flavor profile but often results in a lighter, less intense taste due to minimal heat application during processing.

While toasting intensifies nutty, smoky, and roasted notes, freeze-drying retains moisture-sensitive flavors and nutrients more effectively, maintaining freshness over time. The choice between toasting and freeze-drying depends on desired flavor complexity versus nutrient preservation in snack production.

Texture Comparison: Crunch vs Crisp

Toasting snacks typically results in a crunchy texture by applying dry heat that removes moisture evenly, while freeze-drying preserves a crisp, airy quality by sublimating water content under low temperatures. Texture influences consumer preference, with crunch often linked to warmth and richness, and crisp favored for lightness and freshness.

- Crunch from Toasting - Heat-induced Maillard reactions create firmness and a denser bite in toasted snacks.

- Crisp from Freeze-Drying - Rapid dehydration causes porous structures that break easily, producing a delicate snap.

- Moisture Content - Toasting reduces moisture less aggressively than freeze-drying, impacting textural density.

Choosing between toasting and freeze-drying depends on desired mouthfeel and product shelf stability.

Nutritional Value Retention

Toasting preserves more natural antioxidants and vitamins in snacks compared to freeze-drying, which can cause nutrient degradation due to sublimation. The moderate heat involved in toasting helps retain essential minerals and flavor compounds while reducing moisture content. Freeze-drying excels in maintaining texture and shelf life but may result in a lower retention of heat-sensitive nutrients like vitamin C and certain B vitamins.

Shelf Life and Storage Considerations

Toasting reduces moisture content in snacks, extending shelf life by inhibiting microbial growth, but typically offers a shorter preservation period compared to freeze-drying. Toasted snacks often require airtight packaging and cool, dry storage to maintain freshness and prevent staleness.

Freeze-drying removes nearly all moisture, significantly prolonging shelf life by preserving texture and flavor without refrigeration. Snacks processed this way can be stored at room temperature for years, provided they remain sealed from humidity and oxygen.

Cost and Accessibility for Home Cooks

Toasting snacks at home is cost-effective, requiring only basic kitchen appliances like a toaster or oven, making it highly accessible for most home cooks. Freeze-drying, conversely, involves expensive equipment and higher operational costs, limiting its feasibility for everyday use. The affordability and simplicity of toasting enable greater experimentation with flavors and textures without significant financial investment.

Related Important Terms

Flavor Lock Differential

Toasting enhances snack flavor by triggering Maillard reactions that develop rich, caramelized notes, while freeze-drying primarily preserves original flavors by removing moisture without heat exposure. This flavor lock differential makes toasting ideal for bold, roasted taste profiles, whereas freeze-drying maintains freshness and subtlety.

Texture Amplification Index

Toasting enhances the Texture Amplification Index by creating a crispy, crunchy surface through Maillard reactions, which intensifies the sensory experience of snacks compared to freeze-drying, which primarily preserves texture but results in a lighter, airier mouthfeel. The structural changes induced by toasting increase density and resistance to moisture, amplifying textural contrast and improving overall snack robustness.

Crunch Factor Quotient

Toasting enhances the Crunch Factor Quotient (CFQ) by applying dry heat that reduces moisture content and creates a crispy texture through Maillard reactions, resulting in a satisfying crunch in snacks. Freeze-drying preserves structural integrity and extends shelf life but tends to produce a lighter, more brittle crunch that scores lower on the CFQ compared to toasted snacks.

Nutrient Retention Delta

Toasting preserves more heat-sensitive vitamins like B-complex and antioxidants compared to freeze-drying, which retains overall macronutrients but may degrade certain micronutrients due to the sublimation process. Nutrient retention delta indicates toasting maintains up to 15% higher vitamin levels, while freeze-drying excels in preserving texture and moisture content.

Toasted Aroma Persistence

Toasting enhances the aroma persistence of snacks by inducing Maillard reactions that generate complex, long-lasting flavor compounds, unlike freeze-drying, which preserves original flavors but lacks the development of rich, roasted notes. The prolonged aromatic profile from toasting contributes to a more satisfying sensory experience and increased snack palatability.

Freeze-Crystallization Microstructure

Freeze-drying preserves the freeze-crystallization microstructure by sublimating ice directly from frozen snacks, maintaining cellular integrity and nutrient retention. Toasting, in contrast, alters the microstructure through heat-induced expansion and moisture loss, often resulting in a denser texture and reduced nutritional quality.

Low-Temp Dehydration Snacks

Low-temp dehydration snacks preserve natural flavors, nutrients, and texture more effectively than toasting, which can lead to browning and nutrient loss due to higher temperatures. Freeze-drying offers superior moisture removal and shelf stability but requires costly equipment, while low-temp dehydration provides an energy-efficient alternative that maintains snack quality without the chemical alterations associated with toasting.

Snack Puffing Technology

Snack puffing technology uses rapid heat expansion to create light, airy textures, offering superior crunch and flavor retention compared to freeze-drying, which primarily removes moisture through sublimation. Toasting enhances Maillard reactions for richer taste profiles, whereas freeze-drying preserves nutrients but often results in a less crispy texture.

Heat-Driven Maillard Boost

Toasting enhances snack flavor and color through the heat-driven Maillard reaction, creating complex browning compounds that freeze-drying cannot replicate. Unlike freeze-drying, which preserves texture and nutrients by sublimation at low temperatures, toasting intensifies aroma and crispness by applying direct heat.

Toasting vs Freeze-drying for snacks. Infographic

cookingdiff.com

cookingdiff.com