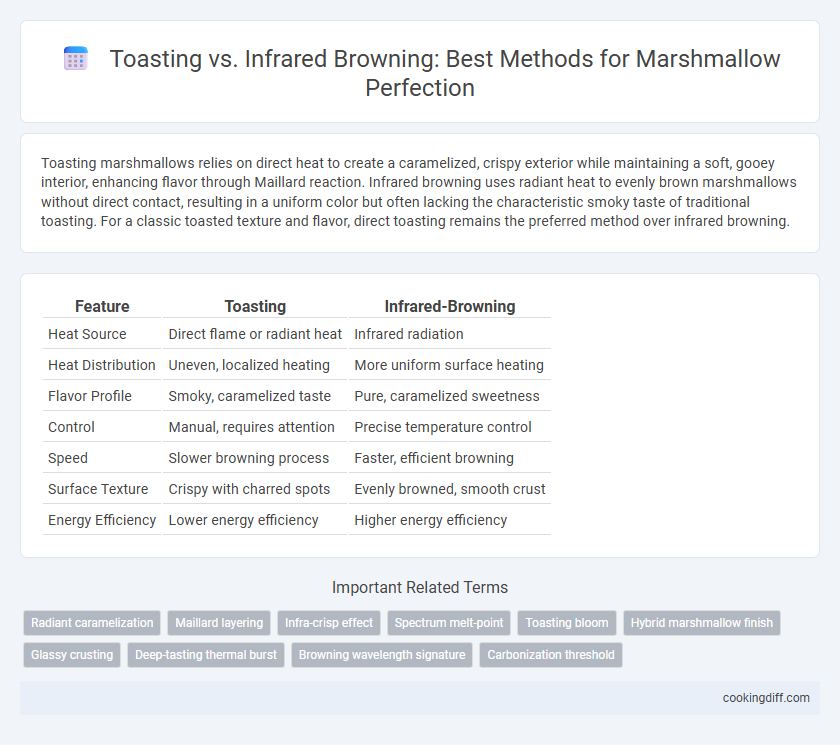

Toasting marshmallows relies on direct heat to create a caramelized, crispy exterior while maintaining a soft, gooey interior, enhancing flavor through Maillard reaction. Infrared browning uses radiant heat to evenly brown marshmallows without direct contact, resulting in a uniform color but often lacking the characteristic smoky taste of traditional toasting. For a classic toasted texture and flavor, direct toasting remains the preferred method over infrared browning.

Table of Comparison

| Feature | Toasting | Infrared-Browning |

|---|---|---|

| Heat Source | Direct flame or radiant heat | Infrared radiation |

| Heat Distribution | Uneven, localized heating | More uniform surface heating |

| Flavor Profile | Smoky, caramelized taste | Pure, caramelized sweetness |

| Control | Manual, requires attention | Precise temperature control |

| Speed | Slower browning process | Faster, efficient browning |

| Surface Texture | Crispy with charred spots | Evenly browned, smooth crust |

| Energy Efficiency | Lower energy efficiency | Higher energy efficiency |

Overview: Toasting vs Infrared-Browning for Marshmallows

Toasting marshmallows involves direct exposure to flame, creating a caramelized, crispy outer layer while maintaining a soft interior. Infrared-browning uses infrared radiation to evenly brown marshmallows without the risk of burning or charring.

- Heat Source Difference - Toasting relies on open flame heat, whereas infrared-browning uses radiant heat energy.

- Control and Consistency - Infrared-browning offers more consistent color control compared to the variable results of traditional toasting.

- Flavor Profile - Toasting imparts a smoky, charred flavor while infrared-browning enhances sweetness with less burnt taste.

What is Traditional Toasting?

Traditional toasting involves exposing marshmallows to an open flame or heat source, allowing the surface to caramelize and develop a golden-brown crust. This method relies on direct contact with fire or hot coals, producing a smoky aroma and enhanced flavor.

Infrared browning uses radiant heat to cook the marshmallow surface evenly without direct flames, resulting in a more controlled and uniform browning. Unlike traditional toasting, infrared does not impart the smoky notes characteristic of campfire toasting.

How Does Infrared-Browning Work?

| Infrared-browning heats marshmallows by emitting infrared radiation that penetrates the surface, causing sugar caramelization without excessive charring. This method creates an even, controlled browning effect by directly exciting water molecules and sugars, maintaining texture and flavor. Infrared heaters provide rapid, uniform heat, reducing cooking time compared to traditional toasting methods. |

Flavor Differences: Toasted vs Infrared-Browned Marshmallows

How do flavor profiles differ between toasted and infrared-browned marshmallows? Toasted marshmallows develop a rich, caramelized exterior with smoky notes due to direct flame exposure, enhancing depth and complexity. Infrared-browned marshmallows offer a more uniform golden color and subtle sweetness without the intense smoky flavor, resulting in a milder taste experience.

Texture Comparison: Crunch, Gooeyness, and Consistency

Toasting marshmallows produces a crunchy outer layer while maintaining a gooey interior, creating a contrast in texture. Infrared-browning yields a more uniform consistency with less crunch but a smooth, evenly melted gooeyness.

- Crunch - Toasting creates a crispy, golden-brown crust that adds a satisfying crunch to each bite.

- Gooeyness - Infrared-browning melts the marshmallow evenly, resulting in a consistently gooey texture throughout.

- Consistency - Toasting produces varied textures with a firm exterior and soft inside, whereas infrared-browning offers a homogenous softness.

Choosing between these methods depends on whether you prefer textural contrast or uniform meltiness in marshmallows.

Equipment Needed for Each Method

Toasting marshmallows traditionally requires a simple setup such as skewers or roasting sticks and an open flame from a campfire or a grill. This method relies on direct heat to evenly brown the marshmallow's surface and achieve the characteristic toasted flavor.

Infrared-browning of marshmallows involves specialized infrared heat lamps or broilers designed to emit controlled radiant heat. This equipment allows precise temperature control and quick browning without burning the marshmallow's exterior.

Speed and Efficiency: Which Method Wins?

Toasting marshmallows with an open flame typically takes 2-3 minutes to achieve an even golden brown, providing control over the browning intensity. Infrared-browning heats marshmallows rapidly within 30-45 seconds due to direct radiant heat, boosting efficiency in commercial settings. For speed and consistent caramelization, infrared-browning outperforms traditional toasting methods.

Safety Considerations: Open Flame vs Infrared Devices

Open flame toasting exposes marshmallows to direct heat sources, increasing the risk of burns and accidental fires, especially in uncontrolled environments. Infrared-browning devices offer a safer alternative by providing consistent, even heating without an open flame, minimizing fire hazards and reducing the chance of uneven charring. Safety standards for infrared appliances typically include automatic shutoff features and temperature controls, enhancing user protection during marshmallow toasting.

Energy Consumption and Environmental Impact

Toasting marshmallows typically consumes less energy compared to infrared-browning, which requires higher power for rapid heating. The environmental impact of toasting is generally lower due to reduced electricity usage and fewer emissions in the production of heat.

- Energy Efficiency - Toasting uses direct flame or lower wattage heating elements, resulting in lower overall energy consumption than infrared-browning methods.

- Carbon Footprint - The lower electricity demand of toasting translates to a smaller carbon footprint compared to the high energy input needed for infrared-browning systems.

- Resource Utilization - Infrared-browning involves specialized equipment with higher manufacturing impacts, whereas toasting relies on simpler tools with fewer environmental resources consumed.

Related Important Terms

Radiant caramelization

Toasting marshmallows achieves radiant caramelization through direct exposure to flame or hot air, creating a rich Maillard reaction that enhances flavor and texture. Infrared-browning uses specific wavelengths to target surface sugars, offering faster caramelization but often lacks the depth of flavor and traditional crispness produced by radiant heat.

Maillard layering

Toasting marshmallows relies on direct heat to initiate Maillard browning, creating a complex flavor profile through protein and sugar reactions on the surface. Infrared-browning achieves similar Maillard layering more uniformly and quickly by using targeted wavelengths that heat the sugars and amino acids without overcooking the interior.

Infra-crisp effect

Infrared-browning for marshmallows produces a distinct infra-crisp effect that creates an evenly caramelized exterior with a delicate, crunchy texture compared to traditional toasting. This method enhances flavor development by targeting moisture reduction at the surface while preserving the soft interior, resulting in a superior crispy yet tender bite.

Spectrum melt-point

Infrared browning achieves precise control over the spectrum melt-point, allowing marshmallows to caramelize evenly without burning. In contrast, traditional toasting methods often generate uneven heat distribution, resulting in inconsistent melt-point exposure and variable texture.

Toasting bloom

Toasting marshmallows creates a Maillard reaction that produces a rich, caramelized flavor and a golden-brown crust, enhancing the toasting bloom's visual and sensory appeal. Infrared-browning offers rapid surface heating but often lacks the depth of flavor and even browning associated with traditional toasting methods.

Hybrid marshmallow finish

Hybrid marshmallow finish combines the caramelized exterior of traditional toasting with the even, controlled heat distribution of infrared browning, resulting in a perfectly toasted texture and enhanced flavor depth. This method reduces charring while maximizing Maillard reaction, delivering a balanced golden crust and a tender, gooey interior.

Glassy crusting

Toasting marshmallows creates a glassy crust by evenly caramelizing the sugars through direct heat, resulting in a glossy, crisp outer layer with a rich, toasted flavor. Infrared-browning, while faster, often produces uneven caramelization that lacks the characteristic glassy texture and depth of flavor achieved by traditional toasting.

Deep-tasting thermal burst

Toasting marshmallows delivers a deep-tasting thermal burst through direct radiant heat, creating caramelization and Maillard reactions that enhance flavor complexity and texture. Infrared-browning offers more controlled heat application but often lacks the intense, smoky depth produced by traditional toasting methods.

Browning wavelength signature

Toasting marshmallows produces a browning wavelength signature primarily in the visible to near-infrared spectrum (600-900 nm), resulting from Maillard reactions and caramelization processes. In contrast, infrared browning emits a more uniform infrared wavelength signature beyond 900 nm, creating consistent surface heating but less complex flavor development compared to traditional toasting.

Toasting vs Infrared-browning for marshmallows. Infographic

cookingdiff.com

cookingdiff.com