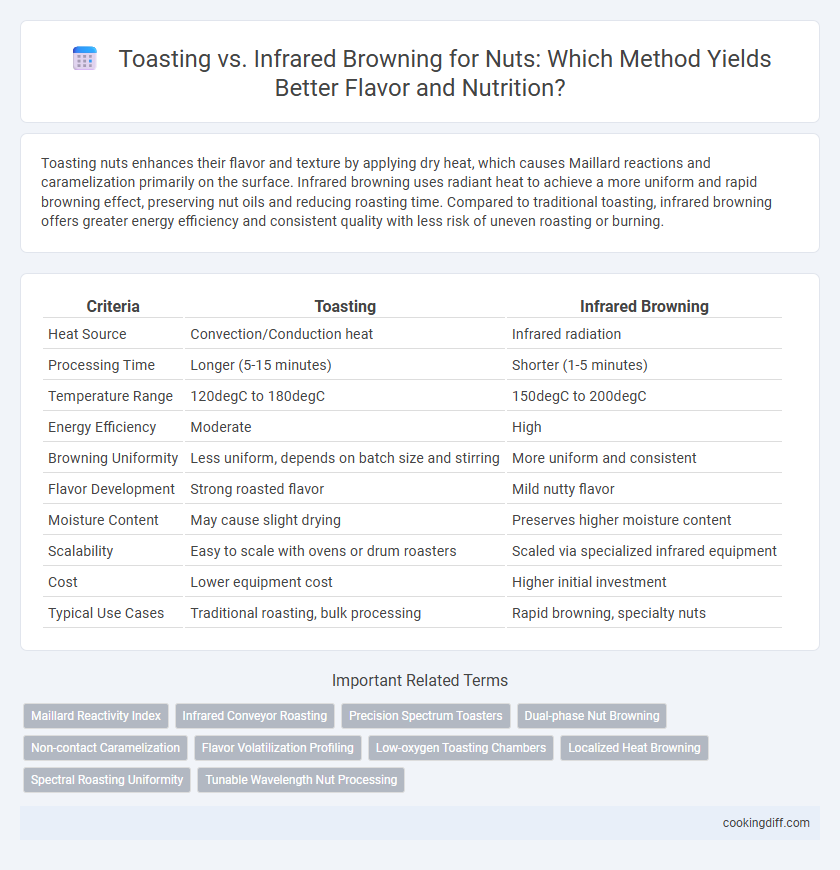

Toasting nuts enhances their flavor and texture by applying dry heat, which causes Maillard reactions and caramelization primarily on the surface. Infrared browning uses radiant heat to achieve a more uniform and rapid browning effect, preserving nut oils and reducing roasting time. Compared to traditional toasting, infrared browning offers greater energy efficiency and consistent quality with less risk of uneven roasting or burning.

Table of Comparison

| Criteria | Toasting | Infrared Browning |

|---|---|---|

| Heat Source | Convection/Conduction heat | Infrared radiation |

| Processing Time | Longer (5-15 minutes) | Shorter (1-5 minutes) |

| Temperature Range | 120degC to 180degC | 150degC to 200degC |

| Energy Efficiency | Moderate | High |

| Browning Uniformity | Less uniform, depends on batch size and stirring | More uniform and consistent |

| Flavor Development | Strong roasted flavor | Mild nutty flavor |

| Moisture Content | May cause slight drying | Preserves higher moisture content |

| Scalability | Easy to scale with ovens or drum roasters | Scaled via specialized infrared equipment |

| Cost | Lower equipment cost | Higher initial investment |

| Typical Use Cases | Traditional roasting, bulk processing | Rapid browning, specialty nuts |

Introduction to Nut Browning Techniques

Nut browning enhances flavor and aroma through Maillard reactions and caramelization processes. Toasting and infrared browning are two primary techniques used to achieve desirable nut coloration and taste.

- Toasting - Uses dry heat with hot air circulation to evenly brown nuts over a longer period, enhancing flavor complexity.

- Infrared browning - Employs shortwave radiation to rapidly heat nut surfaces, creating a distinct, intense browning effect.

- Technique selection - Depends on desired flavor profile, processing time, and energy efficiency requirements.

What is Toasting?

Toasting is a dry heat cooking method that enhances the flavor and texture of nuts by applying direct heat usually through a pan or oven. This process triggers the Maillard reaction, resulting in a rich, nutty aroma and a golden-brown color.

- Heat Application - Toasting uses conventional heat sources like ovens or stovetops to evenly brown nuts.

- Flavor Development - It promotes the Maillard reaction, intensifying the nutty, roasted flavor profiles.

- Texture Changes - Toasting improves crispness and reduces moisture content in nuts.

Understanding Infrared Browning

How does infrared browning differ from traditional toasting when processing nuts? Infrared browning uses radiant heat to penetrate nuts rapidly, causing Maillard reactions that enhance flavor without excessive drying. This method preserves natural oils and nutrients better than conventional toasting, resulting in a crisper texture and richer aroma.

Flavor Profiles: Toasted vs Infrared-Browned Nuts

Toasted nuts develop complex, rich flavor profiles through Maillard reactions and caramelization, enhancing their natural sweetness and producing deep, nutty aromas. This traditional method yields a crunchy texture and a golden-brown color that intensifies the overall sensory experience.

Infrared browning uses radiant heat to quickly brown nuts, preserving more of their original moisture and subtle flavors while creating a lighter, less intense aroma. This technique offers precise control over browning levels, resulting in a more uniform appearance and a milder, roasted taste compared to conventional toasting.

Texture Differences in Nut Preparation

Toasting nuts enhances their texture by creating a crisp outer layer while maintaining a slightly softer interior, contributing to a balanced crunch. Infrared browning, however, tends to produce a more uniform texture with less depth in crunch, as the heat penetrates quickly and evenly. This difference affects the sensory experience, with toasting offering a more complex and desirable texture profile for gourmet nut preparations.

Nutritional Impact of Each Method

| Toasting | Preserves more antioxidants due to gradual heat application; may cause slight nutrient degradation but enhances flavor while maintaining healthy fats. |

| Infrared Browning | Uses intense heat leading to a faster Maillard reaction, potentially reducing nutrient levels like vitamin E and polyunsaturated fats more significantly than toasting. |

| Nutritional Impact Comparison | Toasting maintains higher overall nutrient retention and antioxidant capacity, whereas infrared browning accelerates browning but can diminish heat-sensitive nutrients in nuts. |

Equipment Needed for Toasting and Infrared Browning

Toasting nuts typically requires a conventional oven or a stovetop skillet to evenly apply dry heat, enhancing flavor and texture through Maillard reactions. Infrared browning uses specialized infrared lamps or emitters that provide rapid, focused heat for surface caramelization without significantly increasing the internal temperature. While toasting equipment is more common and versatile in home kitchens, infrared browning devices are primarily found in industrial settings for precise, controlled browning processes.

Time and Efficiency Comparison

Toasting nuts typically requires 10-15 minutes at 350degF, providing even heat distribution but consuming more time and energy. Infrared browning significantly reduces processing time to 3-5 minutes due to rapid surface heating, enhancing overall efficiency.

While toasting offers consistent flavor development, infrared browning maximizes throughput in commercial settings by decreasing cycle times and energy use. This efficiency makes infrared browning a preferred choice for large-scale nut roasting operations aiming to optimize productivity.

Suitability for Different Types of Nuts

Toasting is ideal for nuts like almonds and walnuts that benefit from slow, even heat to develop flavor and crunch without burning. Infrared browning suits harder nuts such as macadamias, providing rapid surface caramelization while preserving interior freshness.

Different nuts require distinct heat applications due to varying oil content and shell thickness. Toasting offers controlled heat penetration, making it better for delicate nuts prone to bitterness when overheated. Infrared browning delivers fast, high-intensity heat, perfect for achieving a uniform tan on tougher nuts with thicker skins.

Related Important Terms

Maillard Reactivity Index

Toasting nuts significantly enhances their Maillard Reactivity Index compared to infrared browning, resulting in richer flavor and deeper color due to prolonged heat exposure and Maillard reaction development. Infrared browning offers rapid surface heating but often limits internal Maillard reactivity, producing less complex flavor profiles and incomplete nut browning.

Infrared Conveyor Roasting

Infrared conveyor roasting offers precise temperature control and uniform heat distribution, resulting in consistent browning and enhanced flavor development of nuts compared to traditional toasting methods. This technology reduces roasting time and minimizes nutrient loss while improving energy efficiency in commercial nut processing.

Precision Spectrum Toasters

Precision Spectrum Toasters offer superior control over the toasting process by utilizing advanced infrared browning technology that ensures even heat distribution and optimal Maillard reaction for nuts, enhancing flavor and texture without burning. Compared to traditional toasting methods, infrared browning enables precise temperature regulation and reduced toasting times, resulting in consistently roasted nuts with improved color uniformity and preserved nutritional value.

Dual-phase Nut Browning

Dual-phase nut browning combines traditional toasting with infrared browning, enhancing flavor development and achieving uniform coloration. Infrared browning penetrates nut surfaces for even heat distribution, while toasting imparts deep, caramelized notes, optimizing texture and aroma in nut processing.

Non-contact Caramelization

Non-contact caramelization in toasting achieves uniform browning of nuts by using hot air circulation, reducing the risk of burning compared to infrared browning, which relies on direct radiant heat and can cause uneven spots. This method enhances flavor development through Maillard reactions while maintaining nut texture and minimizing nutrient loss.

Flavor Volatilization Profiling

Toasting nuts enhances flavor volatilization by promoting Maillard reactions and lipid oxidation, generating complex aromatic compounds that intensify nutty and caramel notes. Infrared browning offers precise heat control, minimizing over-roasting and preserving delicate volatiles, resulting in a more balanced and nuanced flavor profile.

Low-oxygen Toasting Chambers

Low-oxygen toasting chambers enable precise temperature control and reduced oxidation, preserving the natural oils and enhancing the flavor profile of nuts compared to traditional infrared browning, which can cause uneven heating and potential bitterness. This method extends shelf life and maintains nutritional quality by minimizing exposure to oxygen during the roasting process.

Localized Heat Browning

Toasting provides localized heat browning by directly exposing nuts to dry heat, enhancing flavor through Maillard reactions while maintaining a crunchy texture. Infrared browning uses electromagnetic wavelengths to penetrate and evenly heat the nuts, offering uniform browning but sometimes resulting in less distinct surface caramelization compared to traditional toasting.

Spectral Roasting Uniformity

Toasting nuts provides more uniform spectral roasting by allowing consistent heat distribution through convection and conduction, enhancing flavor development and texture. Infrared browning, while faster, often results in uneven roasting due to localized heat spots, compromising the uniformity and overall quality of the nuts.

Toasting vs Infrared browning for nuts. Infographic

cookingdiff.com

cookingdiff.com