Toasting achieves controlled browning through direct heat, producing a crisp texture and enhanced flavor via the Maillard reaction on the surface of foods. Sous-vide Maillard combines precise temperature control with subsequent searing, ensuring even browning while retaining moisture and tenderness inside. This method allows for consistent results and superior flavor development compared to traditional toasting alone.

Table of Comparison

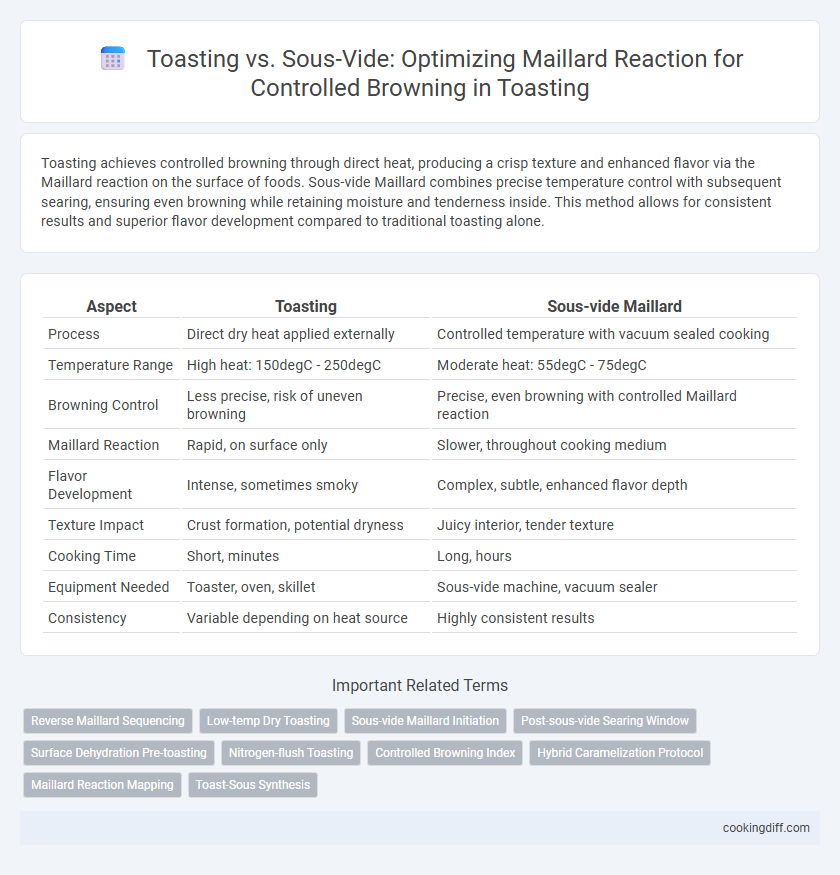

| Aspect | Toasting | Sous-vide Maillard |

|---|---|---|

| Process | Direct dry heat applied externally | Controlled temperature with vacuum sealed cooking |

| Temperature Range | High heat: 150degC - 250degC | Moderate heat: 55degC - 75degC |

| Browning Control | Less precise, risk of uneven browning | Precise, even browning with controlled Maillard reaction |

| Maillard Reaction | Rapid, on surface only | Slower, throughout cooking medium |

| Flavor Development | Intense, sometimes smoky | Complex, subtle, enhanced flavor depth |

| Texture Impact | Crust formation, potential dryness | Juicy interior, tender texture |

| Cooking Time | Short, minutes | Long, hours |

| Equipment Needed | Toaster, oven, skillet | Sous-vide machine, vacuum sealer |

| Consistency | Variable depending on heat source | Highly consistent results |

Introduction to Controlled Browning Techniques

Controlled browning techniques like toasting and sous-vide Maillard reaction enable precise flavor and texture development in cooking. These methods manipulate heat application to optimize the Maillard reaction, enhancing color and taste while preventing overcooking.

- Toasting - Applies direct dry heat to rapidly create a brown, crisp surface through high-temperature Maillard reactions.

- Sous-vide Maillard - Combines low-temperature cooking in a vacuum with a finishing sear for uniform browning and tender texture.

- Controlled Browning - Ensures consistent flavor profiles and reduces nutrient loss by regulating reaction time and temperature.

Understanding these techniques allows chefs to achieve desired sensory qualities with greater precision and repeatability.

Understanding the Maillard Reaction in Cooking

Toasting and sous-vide Maillard each manipulate the Maillard reaction to achieve controlled browning, affecting flavor and texture in distinct ways. Understanding the chemical complexity of this reaction helps optimize cooking techniques for desired sensory outcomes.

- Toasting promotes rapid surface browning - High direct heat accelerates Maillard compounds formation, enhancing crispiness and aroma.

- Sous-vide allows precise temperature control - Lower, steady heat activates Maillard reaction evenly without overcooking interior proteins.

- Maillard reaction is temperature-dependent - Critical threshold typically occurs between 140-165degC, influencing the rate and intensity of browning.

Toasting: Methodology and Browning Potential

Toasting involves dry heat application directly on the surface of food, promoting the Maillard reaction through high temperatures that induce rapid browning and flavor development. This method effectively controls browning intensity by adjusting time and heat, enhancing the sensory attributes of foods like bread, nuts, and coffee beans.

Precise temperature control during toasting ensures consistent browning without overcooking, creating complex flavor compounds and a desirable crispy texture. Unlike sous-vide Maillard, toasting requires no pre-soaking or vacuum sealing, expediting preparation and offering versatility for various food types. The dry heat environment in toasting maximizes surface caramelization, highlighting its superior browning potential in culinary applications.

Sous-Vide Maillard: Science Behind the Process

Sous-vide Maillard achieves controlled browning by precisely regulating temperature and time, allowing the Maillard reaction to develop complex flavors without overcooking the food. This method enhances texture and color uniformly by immersing vacuum-sealed food in a temperature-controlled water bath before finishing with a high-heat sear.

The science behind sous-vide Maillard involves maintaining temperatures just below the threshold where proteins denature too rapidly, optimizing the reaction between amino acids and reducing sugars. This controlled environment minimizes bitterness and burnt notes common in traditional toasting, resulting in a more nuanced caramelization and savory depth.

Key Equipment for Toasting vs Sous-Vide Browning

| Key Equipment | Toasting | Sous-Vide Maillard Browning |

|---|---|---|

| Temperature Control | Simple adjustable heat settings on toaster or pan | Precise immersion circulators maintaining exact temperatures (typically 130-160degC for Maillard reaction) |

| Heat Source | Direct dry heat from electric coils, gas flames, or infrared elements | Initial sous-vide bath uses water bath heat; final browning requires specialized searing devices such as blowtorches or cast iron pans |

| Process Control Tools | Timers and thermostat controls for consistent toasting duration | Combination of immersion circulator for cooking and separate equipment like blowtorches or salamander broilers for controlled Maillard browning |

Flavor Profiles: Toasted vs Sous-Vide Maillard

Toasting creates a complex flavor profile with pronounced nutty and caramelized notes due to direct dry heat exposure. Sous-vide Maillard browning offers controlled, even development of savory and umami flavors by slowly reaching Maillard reaction temperatures. Combining both methods can enhance depth by balancing the intense crispiness of toasted surfaces with the tender, flavor-infused interior from sous-vide cooking.

Texture Differences: Crunch vs Tenderness

Toasting produces a distinct crunchy texture from direct dry heat, while sous-vide Maillard browning maintains tenderness by cooking food gently at low temperatures before browning. The contrast in methods highlights how toasting emphasizes crispness, whereas sous-vide prioritizes a uniformly tender interior with subtle exterior browning.

- Crunch from Toasting - High heat quickly forms a crispy crust by evaporating surface moisture and caramelizing sugars.

- Tenderness from Sous-vide Maillard - Slow, controlled cooking retains juices and softens fibers before applying heat for browning.

- Texture Balance - Toasting excels for crunchy exteriors; sous-vide achieves tenderness with gentle browning, ideal for delicate proteins.

Precision and Control in Browning Outcomes

Toasting offers precise control over browning through adjustable heat levels and direct surface contact, enabling consistent Maillard reactions. This method allows for immediate sensory feedback, which is critical for achieving desired crust texture and color.

Sous-vide Maillard browning provides exceptional temperature regulation but requires a secondary searing step to develop surface color and flavor. Combining sous-vide with controlled toasting optimizes precision in both internal doneness and exterior browning outcomes.

Practical Applications in Home and Professional Kitchens

Toasting offers immediate surface browning through high heat, ideal for quick flavor development in both home and professional kitchens. Sous-vide Maillard allows precise temperature control, resulting in even browning and enhanced tenderness over extended cooking times. Combining toasting with sous-vide techniques optimizes texture and flavor, making it a practical approach for chefs aiming for consistent quality.

Related Important Terms

Reverse Maillard Sequencing

Reverse Maillard sequencing achieves controlled browning by applying sous-vide cooking to develop internal flavors before toasting surface reactions trigger Maillard browning, optimizing taste and texture. This method contrasts traditional toasting, where direct heat induces surface browning first, often risking uneven color and flavor development.

Low-temp Dry Toasting

Low-temp dry toasting enables precise control over Maillard browning by maintaining temperatures around 120-140degC, preserving flavor complexity without overcooking. Unlike sous-vide methods that rely on moisture retention, low-temp dry toasting enhances surface dryness, promoting optimal caramelization and uniform browning for superior taste and texture.

Sous-vide Maillard Initiation

Sous-vide Maillard initiation enables precise temperature control to achieve uniform browning by carefully managing the Maillard reaction kinetics during cooking, resulting in enhanced flavor and texture development. Unlike traditional toasting, sous-vide allows proteins and sugars to react gently before final searing, optimizing controlled browning without risk of burning or uneven color.

Post-sous-vide Searing Window

Post-sous-vide searing provides a narrow yet critical window to achieve optimal Maillard browning, where precise temperature control during toasting enhances flavor without overcooking. This method contrasts with traditional toasting by enabling uniform sear development while maintaining the internal sous-vide-cooked texture.

Surface Dehydration Pre-toasting

Surface dehydration pre-toasting enhances the Maillard reaction by reducing moisture content, enabling more controlled browning compared to sous-vide methods that retain higher surface moisture levels; this dehydration step promotes a crispier texture and deeper flavor development during toasting. Controlled browning through pre-toasting surface dehydration optimizes heat transfer and accelerates Maillard compounds formation, yielding superior crust quality versus the gentler, less dehydrating sous-vide approach.

Nitrogen-flush Toasting

Nitrogen-flush toasting enhances controlled browning by minimizing oxidation and preserving flavor compounds during the Maillard reaction, offering a consistent crust compared to traditional sous-vide methods. This technique ensures uniform heat distribution and maintains product quality by reducing moisture loss and extending shelf life in baked goods and roasted foods.

Controlled Browning Index

The Controlled Browning Index (CBI) quantifies the precise Maillard reaction levels achieved through toasting versus sous-vide methods, with toasting producing faster surface browning due to direct dry heat and sous-vide enabling uniform, gradual browning by controlling temperature and time. Optimizing CBI through sous-vide results in consistent doneness and enhanced flavor development without overcooking, unlike toasting which risks uneven browning and char.

Hybrid Caramelization Protocol

The Hybrid Caramelization Protocol integrates precise temperature control from sous-vide with the intense heat of toasting to optimize Maillard reactions and achieve uniform browning without overcooking. This method enhances flavor complexity and texture by balancing controlled heat exposure and moisture retention during the caramelization process.

Maillard Reaction Mapping

Toasting achieves rapid surface browning by applying direct heat, facilitating Maillard Reaction Mapping that precisely controls flavor and color development on food surfaces. Sous-vide combined with Maillard allows uniform internal cooking before targeted browning, optimizing sweetness and aroma through controlled Maillard reaction gradients.

Toasting vs Sous-vide Maillard for controlled browning Infographic

cookingdiff.com

cookingdiff.com