Toasting sandwiches uses direct heat to create a browned, crispy exterior while evenly warming the inside, enhancing flavors and texture. Infrared crisping, by contrast, relies on radiant heat to quickly sear the surface, often producing a crunchier crust without thoroughly heating the sandwich interior. Choosing between toasting and infrared crisping depends on whether a more uniform warmth or a sharper, faster crisp is desired for the perfect sandwich experience.

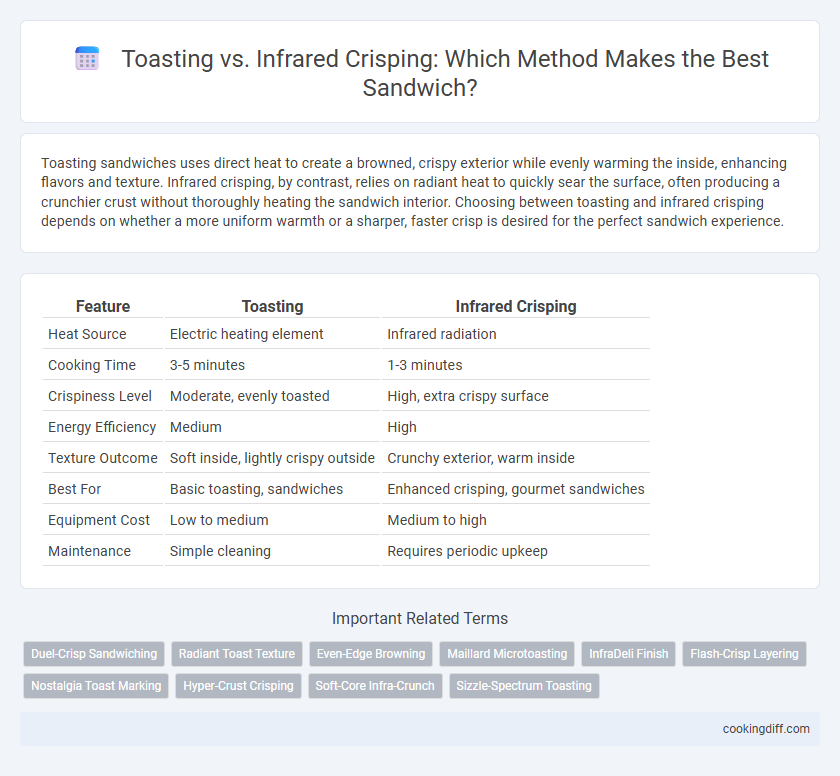

Table of Comparison

| Feature | Toasting | Infrared Crisping |

|---|---|---|

| Heat Source | Electric heating element | Infrared radiation |

| Cooking Time | 3-5 minutes | 1-3 minutes |

| Crispiness Level | Moderate, evenly toasted | High, extra crispy surface |

| Energy Efficiency | Medium | High |

| Texture Outcome | Soft inside, lightly crispy outside | Crunchy exterior, warm inside |

| Best For | Basic toasting, sandwiches | Enhanced crisping, gourmet sandwiches |

| Equipment Cost | Low to medium | Medium to high |

| Maintenance | Simple cleaning | Requires periodic upkeep |

Introduction: Toasting vs. Infrared Crisping

Toasting sandwiches uses direct heat to brown and crisp bread, enhancing flavor through the Maillard reaction. Infrared crisping employs radiant heat to quickly achieve a crispy texture without drying out the filling. Both methods optimize sandwich texture but differ in heat distribution and cooking speed.

What Is Traditional Toasting?

Traditional toasting uses direct heat from elements or a heated surface to brown the bread and warm the sandwich filling. This method relies on conduction and convection to achieve a crispy exterior while melting the interior ingredients.

Infrared crisping, by contrast, employs infrared radiation to heat the sandwich rapidly, creating a distinct texture and enhanced browning. Understanding the mechanics of traditional toasting helps in comparing its benefits against infrared techniques for sandwich preparation.

Understanding Infrared Crisping Technology

Infrared crisping technology uses radiant heat to quickly brown and crisp sandwich surfaces without compressing the ingredients, preserving texture and flavors more effectively than traditional toasting. Unlike convection toasting, infrared heaters target the sandwich's exterior, creating a uniform, golden crust while maintaining a moist interior. This method enhances sandwich quality by reducing cooking time and avoiding sogginess typically associated with standard toasters.

Heating Methods Compared

Toasting uses direct heat contact to brown bread surfaces evenly, while infrared crisping employs radiant energy to heat the sandwich quickly and intensely. The difference in heat transfer results in varied texture and flavor development in sandwiches.

- Heat Transfer Method - Toasting relies on conduction through heated plates, whereas infrared crisping uses electromagnetic radiation to penetrate and cook the sandwich.

- Texture Outcome - Toasting creates a uniform, golden-brown crust, while infrared crisping produces a faster, crisper outer layer with potential for slight charring.

- Energy Efficiency - Infrared crisping typically consumes less energy due to rapid heat delivery compared to the longer duration required for traditional toasting.

Texture and Taste Differences

How do toasting and infrared crisping compare in texture and taste for sandwiches? Toasting typically produces a crunchy, evenly browned surface that enhances the sandwich's flavor through Maillard reactions. Infrared crisping, on the other hand, creates a crisp exterior with a slightly lighter texture and can preserve more of the sandwich's moist interior taste.

Speed and Efficiency: Which Wins?

Toasting sandwiches generally offers faster preparation times due to direct heat application, making it ideal for quick service. Infrared crisping, while slightly slower, provides more even heating and superior crust texture, enhancing overall sandwich quality.

- Toasting Speed - Traditional toasters can heat sandwiches in under 5 minutes, optimizing fast-paced environments.

- Infrared Efficiency - Infrared systems use radiant heat to evenly crisp sandwiches, reducing the need for flipping or repositioning.

- Energy Consumption - Infrared crisping tends to use less energy by focusing heat precisely, lowering operational costs.

Choosing between toasting and infrared crisping depends on whether speed or texture quality has higher priority in your sandwich preparation process.

Nutritional Impact of Each Method

Toasting sandwiches typically involves dry heat that can reduce moisture content and slightly degrade heat-sensitive vitamins like vitamin C and some B vitamins. Infrared crisping uses high-energy waves that cook food quickly, preserving more nutrients due to shorter exposure times and less heat penetration.

Both methods minimize added fats compared to frying, but infrared crisping may better maintain protein integrity and antioxidant levels. Nutritional differences are subtle, yet infrared crisping often supports a higher retention of heat-sensitive nutrients while achieving desirable texture.

Best Sandwich Types for Each Technique

Toasting suits sandwiches with thicker, sturdier breads like ciabatta or sourdough, as the direct heat ensures a crunchy exterior and melted interior. Infrared crisping excels with delicate, thin breads such as baguettes or white sandwich bread, offering even browning without drying the crumb.

For hearty sandwiches filled with robust ingredients like grilled vegetables, cheese, and meats, toasting provides the ideal texture and temperature contrast. Infrared crisping enhances lighter sandwiches such as paninis or toasted wraps, preserving moisture while creating a crisp surface. Each method tailors the sandwich experience to the bread type and filling density, maximizing flavor and texture.

Equipment and Cost Considerations

| Toasting Equipment | Traditional toasters and panini presses are widely available, generally affordable, and require minimal maintenance. They use electrical heating elements to brown bread and melt fillings efficiently. |

| Infrared Crisping Equipment | Infrared crispers utilize infrared radiation to heat sandwiches faster and provide a crisp texture without excessive drying. These units tend to have higher upfront costs and may require specialized installation and calibration. |

| Cost Considerations | Toasting equipment typically involves lower initial investment and operational costs; however, infrared crisping offers energy efficiency and faster cooking times that can reduce long-term expenses in high-volume settings. |

Related Important Terms

Duel-Crisp Sandwiching

Dual-crisp sandwiching combines traditional toasting and infrared crisping to achieve a perfectly balanced texture, delivering a golden, crunchy exterior while retaining a moist, flavorful interior. Infrared crisping targets precise heat distribution, enhancing cheese melt and bread crunchiness faster than conventional toasting methods alone.

Radiant Toast Texture

Radiant toast texture achieved through toasting delivers a uniform golden-brown crispness by evenly exposing the bread to direct radiant heat, enhancing flavor and crunch. Infrared crisping, while faster, often results in uneven browning and a less consistent crust, affecting the overall sensory experience of sandwiches.

Even-Edge Browning

Toasting ensures even-edge browning by applying consistent heat and pressure across the entire surface of the sandwich, resulting in a uniformly crisp texture. Infrared crisping often produces uneven browning, with hotter central areas and less cooked edges, reducing overall sandwich quality.

Maillard Microtoasting

Maillard microtoasting enhances sandwiches by creating complex flavor compounds through precise heat control, unlike infrared crisping which primarily focuses on surface browning without deep flavor development. This technique achieves superior crust texture and rich aroma by promoting gradual protein-sugar reactions at the sandwich's surface.

InfraDeli Finish

InfraDeli Finish leverages advanced infrared crisping technology to deliver evenly toasted sandwiches with a perfectly crisp exterior and warm, flavorful interior. Unlike traditional toasting, InfraDeli Finish uses focused infrared heat to reduce cooking time while enhancing texture and preserving moisture.

Flash-Crisp Layering

Flash-crisp layering in toasting creates a golden-brown, evenly textured surface by applying intense, direct heat that quickly vaporizes moisture and crisps the sandwich exterior. Infrared crisping uses radiant heat to penetrate deeper, resulting in faster browning but often lacks the layered crunch and distinct texture achieved through traditional toasting methods.

Nostalgia Toast Marking

Toasting sandwiches creates nostalgic toast marks that enhance visual appeal and evoke traditional comfort, while infrared crisping provides even browning without distinct grill patterns. These iconic grill lines deliver sensory satisfaction and reinforce a classic toasted sandwich experience unmatched by infrared methods.

Hyper-Crust Crisping

Hyper-Crust Crisping offers a superior toasting method for sandwiches by utilizing focused infrared heat that penetrates quickly and evenly, creating a perfectly crispy and golden exterior without over-drying the interior. Unlike traditional toasting, this technology enhances flavor retention and texture by precisely controlling surface browning and moisture evaporation.

Soft-Core Infra-Crunch

Soft-Core Infra-Crunch technology combines infrared crisping with toasting to deliver sandwiches that maintain a warm, soft interior while achieving a perfectly crisp outer layer; this method enhances flavor and texture by targeting moisture retention and Maillard reaction efficiency. Compared to traditional toasting, infrared crisping in Soft-Core Infra-Crunch reduces cooking time and prevents sogginess, optimizing sandwich quality with a balanced crunch and tender core.

Toasting vs Infrared crisping for sandwiches. Infographic

cookingdiff.com

cookingdiff.com