Toasting sandwiches uses radiant heat to create a crispy, golden exterior while maintaining a warm, soft interior, enhancing flavor and texture through Maillard reactions. Infrared heating provides faster, more even heat distribution by directly transferring energy to the sandwich surface, reducing cooking times and energy consumption. Unlike traditional toasting, infrared technology minimizes moisture loss, resulting in a juicier, more evenly heated sandwich with a consistent crust.

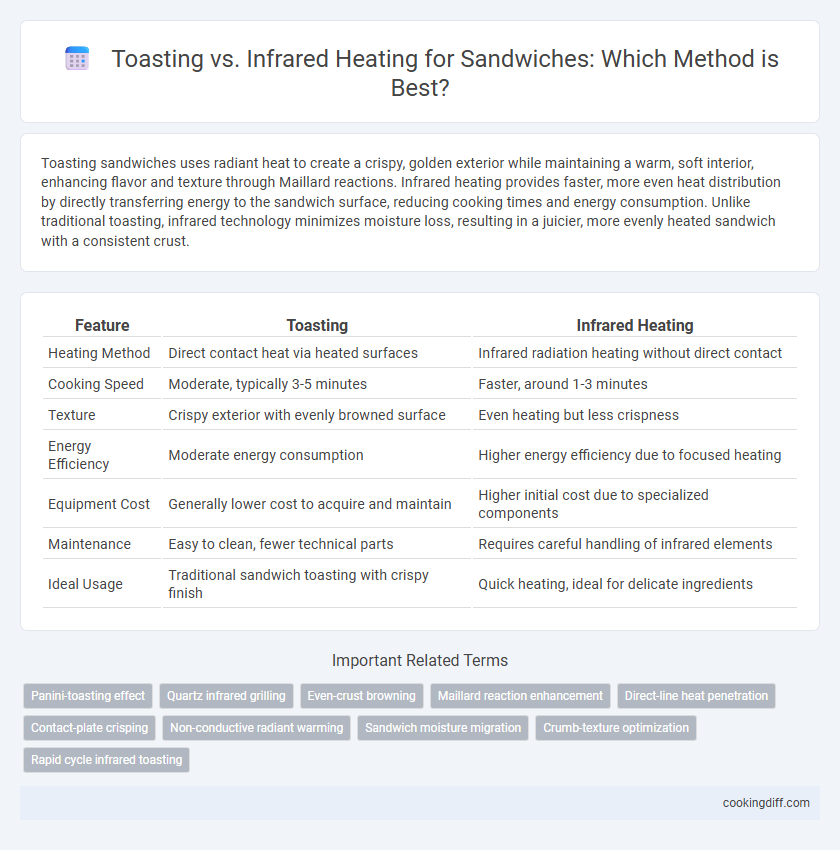

Table of Comparison

| Feature | Toasting | Infrared Heating |

|---|---|---|

| Heating Method | Direct contact heat via heated surfaces | Infrared radiation heating without direct contact |

| Cooking Speed | Moderate, typically 3-5 minutes | Faster, around 1-3 minutes |

| Texture | Crispy exterior with evenly browned surface | Even heating but less crispness |

| Energy Efficiency | Moderate energy consumption | Higher energy efficiency due to focused heating |

| Equipment Cost | Generally lower cost to acquire and maintain | Higher initial cost due to specialized components |

| Maintenance | Easy to clean, fewer technical parts | Requires careful handling of infrared elements |

| Ideal Usage | Traditional sandwich toasting with crispy finish | Quick heating, ideal for delicate ingredients |

Understanding Toasting and Infrared Heating Methods

| Toasting | Toasting uses direct contact heat from heated plates or coils to brown bread surfaces, creating a crisp texture and enhanced flavor through Maillard reactions. |

| Infrared Heating | Infrared heating employs radiant energy to penetrate sandwiches, heating ingredients evenly without direct contact, which preserves moisture and reduces toasting time. |

| Comparison | While toasting excels at producing a crunchy exterior, infrared heating offers faster energy transfer and uniform warming, making it ideal for sandwiches with multiple layers and fillings. |

Fundamental Differences Between Toasting and Infrared Heating

Toasting uses direct contact with heated surfaces to brown and crisp sandwich bread, relying on conduction and convection heat transfer. Infrared heating emits electromagnetic waves that penetrate surface layers, providing even heating without direct contact.

Toasting results in a distinct toasted texture and flavor by caramelizing sugars on the bread's surface, while infrared heating rapidly warms sandwiches without extensive browning. These fundamental differences affect cooking time, texture, and energy efficiency in sandwich preparation.

How Toasting Affects Sandwich Texture and Flavor

Toasting sandwiches creates a crispy, golden crust that enhances both texture and flavor through the Maillard reaction, developing rich, savory notes. Infrared heating, while efficient, often produces a softer texture without the same depth of roasted aroma.

- Crisp Texture Formation - Toasting dries the bread surface, forming a crunchy exterior that contrasts with the softer interior.

- Enhanced Flavor Development - The Maillard reaction during toasting generates complex flavors not typically achieved with infrared heating.

- Moisture Retention - Toasting allows controlled moisture evaporation, balancing firmness and juiciness in the sandwich.

Infrared Heating: Technology and Benefits for Sandwiches

Infrared heating uses electromagnetic waves to directly transfer heat to sandwich surfaces, ensuring even cooking and a crispy texture without drying out the bread. This technology offers rapid heating, reducing preparation time while preserving the sandwich's moisture and flavors. Infrared heating also provides energy efficiency by targeting only the sandwich, minimizing heat loss compared to traditional toasting methods.

Speed and Efficiency: Comparing Toasting and Infrared Heating

Which method heats sandwiches faster and more efficiently: toasting or infrared heating? Infrared heating penetrates sandwiches quickly, reducing cook times and preserving moisture better than traditional toasting. This leads to higher energy efficiency and faster service in commercial sandwich preparation.

Energy Consumption: Toasting vs Infrared Heating

Toasting typically consumes more energy due to longer heating times required to evenly cook sandwiches, averaging around 800-1200 watts per use. Infrared heating uses focused radiation to heat sandwiches quickly, reducing energy consumption by up to 30% compared to traditional toasters.

Infrared heating's efficiency stems from direct heat transfer, minimizing energy loss to the surrounding environment. This energy-saving method makes infrared technology a more sustainable choice for frequent sandwich preparation in both household and commercial settings.

Crispness and Moisture Retention in Sandwiches

Toasting sandwiches using traditional methods provides a crispy exterior while preserving moisture within the bread. Infrared heating, however, can deliver faster crispness but may risk drying out the sandwich if not carefully controlled.

Infrared heating emits intense radiant energy that quickly browns the surface, enhancing crispness without prolonged exposure to heat. This method can better retain the sandwich's internal moisture by reducing overall cooking time. Properly calibrated infrared equipment thus achieves an optimal balance between a crunchy crust and a juicy interior, surpassing conventional toasting in texture quality.

Suitability for Different Bread and Filling Types

Toasting provides a consistent, even heat that crisps various bread types like sourdough and whole grain, enhancing texture without drying out fillings such as cheese or vegetables. Infrared heating delivers rapid surface browning ideal for thin or pre-cooked fillings but may struggle with thicker breads or moisture-sensitive ingredients.

- Toasting excels with thick, dense breads - it evenly crisps the crust while gently warming fillings without overcooking.

- Infrared heating suits delicate, thin breads - it quickly browns the exterior but may cause uneven heating in thicker sandwiches.

- Fillings like cheese melt uniformly in toasting - infrared heating risks overheating or drying out moist fillings due to focused surface heat.

Choosing between toasting and infrared heating depends on the bread's thickness and the moisture content of sandwich fillings for optimal texture and flavor.

Safety and Maintenance Considerations

Toasting uses direct contact heat, which generally poses fewer burn risks compared to the higher surface temperatures of infrared heating that can cause accidental contact burns. Maintenance for toasters is typically simpler, involving regular crumb tray cleaning, whereas infrared appliances require careful handling to avoid lens damage and more frequent calibration. Both methods demand adherence to safety guidelines, but infrared systems often necessitate more specialized knowledge to maintain optimal performance and prevent hazards.

Related Important Terms

Panini-toasting effect

Panini toasting uses direct heat and pressure to create a crispy, golden crust with perfectly melted fillings, enhancing flavor and texture more effectively than infrared heating, which relies on radiant heat that may result in uneven warming. The mechanical pressing in panini toasting ensures consistent grilling marks and a compact sandwich structure, offering a superior sensory experience compared to the gentler, slower heat distribution of infrared methods.

Quartz infrared grilling

Quartz infrared grilling provides rapid and even heat penetration, ensuring sandwiches are toasted quickly with a crispy exterior and perfectly melted interior. Compared to traditional toasting, quartz infrared heating offers superior energy efficiency and precise temperature control, reducing cooking time while enhancing flavor and texture.

Even-crust browning

Toasting achieves more even-crust browning on sandwiches by using direct contact heat that uniformly crisps the bread's surface. Infrared heating often results in uneven browning due to localized hotspots and less consistent heat distribution across the sandwich crust.

Maillard reaction enhancement

Toasting sandwiches enhances the Maillard reaction by providing direct, dry heat that promotes rapid browning and complex flavor development, while infrared heating offers more controlled, even heat distribution that can intensify surface caramelization without overcooking. Infrared technology often achieves a crispier crust and richer taste with greater energy efficiency compared to traditional toasting methods.

Direct-line heat penetration

Toasting delivers direct-line heat penetration by applying consistent, high-temperature contact, which crisps the sandwich exterior while evenly warming the inside. Infrared heating uses radiant energy that penetrates quickly but may cause uneven heating, resulting in less uniform texture compared to traditional toasting methods.

Contact-plate crisping

Contact-plate toasting uses direct heat transfer through heated plates, producing evenly crisped sandwich surfaces with reliable browning and minimal moisture loss. Infrared heating relies on radiant energy, often resulting in uneven crust formation and less effective crisping compared to the consistent pressure and conduction of contact plates.

Non-conductive radiant warming

Toasting uses conductive heat transfer by pressing the sandwich between hot surfaces, while infrared heating relies on non-conductive radiant warming that penetrates the food, ensuring even heat distribution without direct contact. Infrared toasting preserves moisture and texture better, making it ideal for precisely warming sandwiches without drying or burning the bread.

Sandwich moisture migration

Toasting sandwiches uses direct contact heat, causing moisture migration from the bread to the filling, often resulting in soggier textures. Infrared heating reduces this effect by evenly distributing heat without direct contact, preserving sandwich crispness and maintaining optimal moisture balance.

Crumb-texture optimization

Toasting enhances crumb texture by producing a golden-brown, crispy surface that contrasts with the soft interior of sandwiches, while infrared heating provides more uniform heat but may result in a less pronounced crust. Optimizing crumb texture favors toasting techniques that ensure even browning and moisture retention for a satisfying crunch and flavor complexity.

Toasting vs Infrared heating for sandwiches. Infographic

cookingdiff.com

cookingdiff.com