Toasting seeds using traditional methods involves direct heat that evenly browns and enhances their natural flavors, while infrared toasting employs radiant heat for faster, more energy-efficient processing with precise temperature control. Infrared toasting minimizes the risk of burning and preserves nutritional qualities by delivering consistent heat without prolonged exposure. This technique offers improved flavor development and texture retention, making it a superior choice for high-quality seed toasting applications.

Table of Comparison

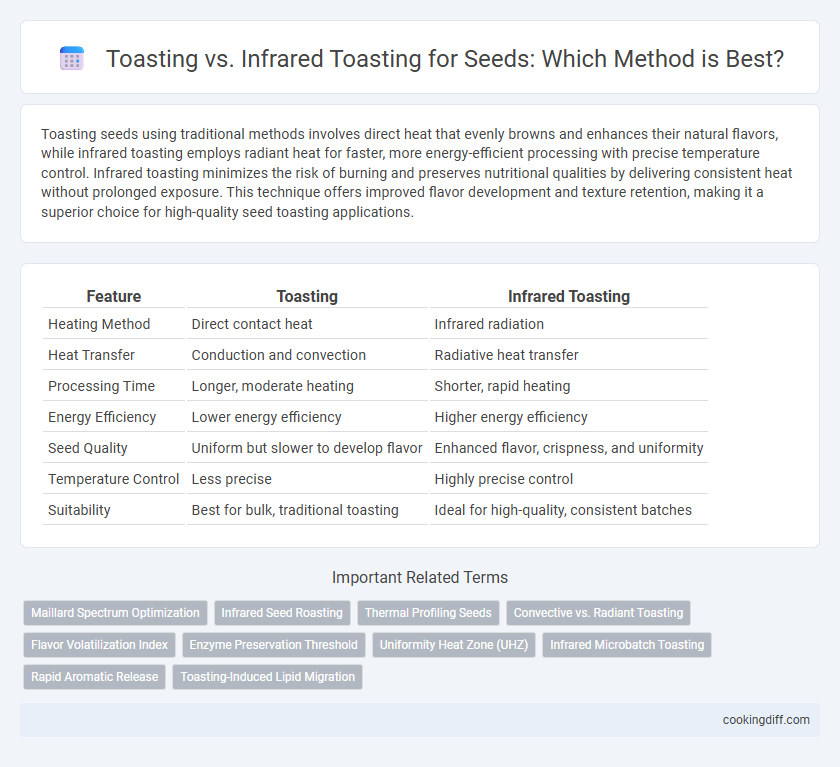

| Feature | Toasting | Infrared Toasting |

|---|---|---|

| Heating Method | Direct contact heat | Infrared radiation |

| Heat Transfer | Conduction and convection | Radiative heat transfer |

| Processing Time | Longer, moderate heating | Shorter, rapid heating |

| Energy Efficiency | Lower energy efficiency | Higher energy efficiency |

| Seed Quality | Uniform but slower to develop flavor | Enhanced flavor, crispness, and uniformity |

| Temperature Control | Less precise | Highly precise control |

| Suitability | Best for bulk, traditional toasting | Ideal for high-quality, consistent batches |

Introduction to Seed Toasting Methods

Toasting is a traditional method used to enhance the flavor and aroma of seeds by applying dry heat. Infrared toasting utilizes infrared radiation to deliver precise and uniform heat, improving efficiency and consistency in seed processing.

Seed toasting effectively reduces moisture content and activates essential oils, resulting in richer taste profiles for various culinary applications. Infrared toasting offers rapid heat transfer and energy savings while minimizing nutrient loss during the toasting process. Both methods play crucial roles in optimizing seed quality for food production and consumption.

What is Traditional Toasting?

What is traditional toasting in seed processing? Traditional toasting involves heating seeds using direct dry heat methods such as open flames or heated pans to enhance flavor and aroma. This process relies on conduction and convection, often resulting in uneven heat distribution compared to infrared toasting methods.

Understanding Infrared Toasting Technology

Infrared toasting technology uses radiant heat to evenly toast seeds, enhancing flavor without the risk of burning. This method offers precise temperature control and consistent results compared to traditional toasting.

- Infrared heating - penetrates seeds uniformly, ensuring even toasting throughout.

- Energy efficiency - Infrared toasters consume less power by targeting only the seed surface.

- Reduced oxidation - rapid heating minimizes seed exposure to oxygen, preserving nutritional quality.

Understanding infrared toasting technology helps optimize seed processing through improved flavor and quality control.

Heat Distribution: Traditional vs Infrared

| Aspect | Traditional Toasting | Infrared Toasting |

|---|---|---|

| Heat Distribution | Relies on convective and conductive heat, causing uneven temperature zones and potential hot spots on seeds. | Uses infrared radiation to deliver consistent and precise heat, promoting uniform toasting and enhanced seed flavor development. |

Flavor Development in Toasted Seeds

Toasting seeds enhances flavor development by promoting Maillard reactions and caramelization, which intensify nutty and complex aromatic profiles. Infrared toasting provides rapid, uniform heat that preserves volatile oils and elevates flavor precision without burning. Conventional toasting, while slower, allows gradual flavor layering but risks uneven roasting and bitterness if not carefully monitored.

Nutrient Retention: Comparing Both Methods

Toasting seeds using traditional methods often results in higher nutrient degradation, especially of heat-sensitive vitamins like vitamin E and certain antioxidants. Infrared toasting employs targeted heat radiation that penetrates seeds more evenly and rapidly, preserving more essential nutrients and maintaining seed quality. Studies indicate infrared toasting can retain up to 30% more antioxidants and essential fatty acids compared to conventional toasting techniques.

Speed and Efficiency of Seed Toasting

Infrared toasting significantly reduces the time required to toast seeds compared to traditional methods by providing rapid and uniform heat distribution. This efficiency helps in preserving seed quality and nutritional content while boosting production throughput.

- Faster Heat Penetration - Infrared technology penetrates seeds quickly, cutting down toasting time by up to 50% compared to conventional toasting methods.

- Even Heating - Infrared toasting ensures uniform temperature across all seeds, minimizing the risk of under- or over-toasting individual seeds.

- Energy Efficiency - Infrared toasting uses less energy by targeting heat directly to the seeds, reducing overall operational costs and environmental impact.

Equipment and Cost Considerations

Toasting equipment for seeds typically includes convection toasters that use hot air, offering uniform heat distribution but often requiring higher initial investment and maintenance costs. Infrared toasting machines use radiant heat technology, which generally reduces energy consumption and operational expenses due to faster heating times and focused energy delivery.

While conventional toasters may involve bulkier machinery with complex controls increasing space and cost requirements, infrared toasters tend to be more compact and energy-efficient, resulting in lower long-term costs. Cost considerations should also factor in the scale of production, as infrared systems can provide better precision and quicker results for small to medium seed processing setups.

Safety and Consistency Concerns

Traditional toasting of seeds often involves uneven heat distribution, creating safety risks like burning or smoke inhalation. Infrared toasting offers more consistent temperature control, reducing the likelihood of overheating and ensuring safer operation.

- Uneven Heating Risks - Conventional toasting can cause hotspots that increase fire hazards and product inconsistency.

- Temperature Precision - Infrared toasting maintains uniform heat levels, preventing seed charring and potential toxic fumes.

- Operator Safety - Controlled infrared systems minimize exposure to open flames and smoke, improving workplace safety.

Related Important Terms

Maillard Spectrum Optimization

Toasting seeds using traditional methods enhances flavor through the Maillard reaction, developing a rich spectrum of roasted notes, while infrared toasting offers precise control over temperature and duration, optimizing Maillard spectrum outcomes by minimizing burnt flavors and maximizing aroma complexity. Infrared toasting accelerates the browning process, producing consistent seed texture and superior flavor profiles by targeting specific wavelengths that promote efficient Maillard reactions.

Infrared Seed Roasting

Infrared seed roasting offers precise temperature control and uniform heat distribution, enhancing flavor development and preserving nutritional quality compared to traditional toasting methods. This technology reduces roasting time while minimizing the risk of seed scorching, resulting in a consistent, high-quality toasted seed product.

Thermal Profiling Seeds

Thermal profiling seeds during toasting ensures uniform heat distribution critical for flavor development and optimal nutrient retention, with conventional toasting offering gradual temperature rise while infrared toasting provides rapid, targeted heat application. Infrared toasting's precise thermal control reduces overheating risks and preserves seed integrity compared to traditional methods, making it ideal for delicate seed varieties requiring consistent thermal exposure.

Convective vs. Radiant Toasting

Convective toasting uses hot air circulation to evenly heat seeds, ensuring uniform moisture removal and enhanced flavor development, while radiant toasting employs infrared radiation to directly transfer heat, resulting in faster surface browning but potentially uneven internal heating. Choosing between convective and radiant methods depends on the desired balance between evenness and speed in seed toasting processes.

Flavor Volatilization Index

Toasting seeds using traditional methods enhances flavor through moderate heat exposure, while infrared toasting significantly boosts the Flavor Volatilization Index by rapidly intensifying the release of aromatic compounds. Infrared toasting's precise heat control preserves essential oils and maximizes flavor profiles, outperforming conventional toasting techniques in sensory quality and overall seed flavor enhancement.

Enzyme Preservation Threshold

Toasting seeds maintains enzyme preservation by carefully controlling temperatures below the critical enzyme denaturation threshold, typically around 60-70degC, whereas infrared toasting often exceeds this range, risking enzyme activity loss. Precise temperature regulation in traditional toasting ensures optimal nutrient retention and functional enzyme integrity compared to infrared methods.

Uniformity Heat Zone (UHZ)

Toasting seeds using traditional methods often results in uneven heat distribution across the Uniformity Heat Zone (UHZ), causing inconsistent roasting and flavor development. Infrared toasting technology enhances uniformity within the UHZ by delivering precise, consistent heat, improving seed quality and flavor uniformity.

Infrared Microbatch Toasting

Infrared Microbatch Toasting offers precise temperature control and rapid heat transfer, resulting in uniform seed toasting without burning or flavor degradation. Compared to conventional toasting methods, it enhances nutritional retention and intensifies flavor profiles by evenly toasting seeds in small, controlled batches.

Rapid Aromatic Release

Infrared toasting for seeds enables rapid aromatic release by penetrating deeply and evenly, enhancing flavor and aroma within seconds compared to conventional toasting methods. This technique preserves seed integrity and maximizes volatile compounds, resulting in a more intense and consistent sensory profile.

Toasting vs Infrared toasting for seeds. Infographic

cookingdiff.com

cookingdiff.com