Toasting garlic enhances its flavor by gently caramelizing its natural sugars and releasing aromatic oils, resulting in a rich, nutty taste. Plasma toasting, however, uses ionized gas to achieve rapid, even heating without direct contact, preserving garlic's freshness while intensifying its flavor profile. Compared to traditional toasting, plasma toasting offers precise temperature control and reduced risk of burning, making it ideal for delicate garlic applications.

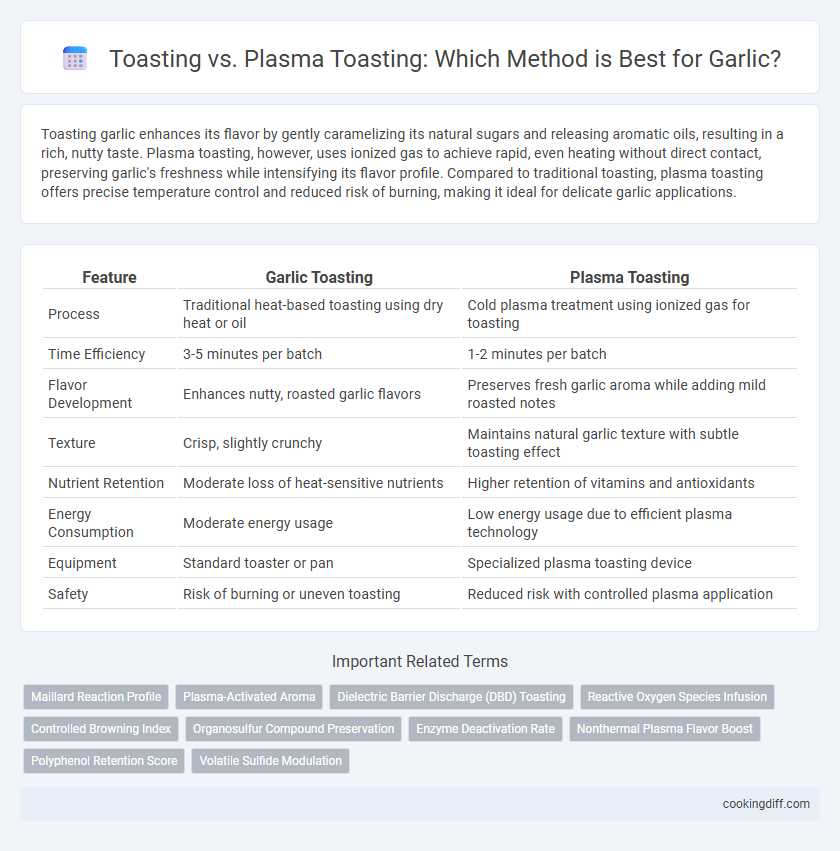

Table of Comparison

| Feature | Garlic Toasting | Plasma Toasting |

|---|---|---|

| Process | Traditional heat-based toasting using dry heat or oil | Cold plasma treatment using ionized gas for toasting |

| Time Efficiency | 3-5 minutes per batch | 1-2 minutes per batch |

| Flavor Development | Enhances nutty, roasted garlic flavors | Preserves fresh garlic aroma while adding mild roasted notes |

| Texture | Crisp, slightly crunchy | Maintains natural garlic texture with subtle toasting effect |

| Nutrient Retention | Moderate loss of heat-sensitive nutrients | Higher retention of vitamins and antioxidants |

| Energy Consumption | Moderate energy usage | Low energy usage due to efficient plasma technology |

| Equipment | Standard toaster or pan | Specialized plasma toasting device |

| Safety | Risk of burning or uneven toasting | Reduced risk with controlled plasma application |

Introduction: Understanding Traditional Toasting and Plasma Toasting

Traditional toasting involves applying dry heat to garlic, enhancing its flavor through Maillard reactions and caramelization. Plasma toasting, a cutting-edge technique, uses ionized gas to achieve a more uniform and rapid toasting process without direct contact. Understanding these methods reveals differences in flavor development, texture, and efficiency in garlic preparation.

What is Traditional Toasting for Garlic?

Traditional toasting for garlic involves gently heating sliced or minced garlic in a dry pan or with a small amount of oil until it turns golden brown and releases a nutty aroma. This method enhances the garlic's natural sweetness and adds depth to its flavor profile.

The process requires careful attention to prevent burning, as over-toasting can result in bitterness. Traditional toasting allows for even heat distribution, preserving the delicate texture and imparting a rich, toasted character. It remains a popular technique in cooking to maximize garlic's culinary impact without altering its essential qualities.

Plasma Toasting: A New Culinary Technique

Plasma toasting introduces a revolutionary approach to garlic preparation by using ionized gas to evenly toast cloves without burning. This method preserves garlic's natural flavors and enhances its aromatic compounds more effectively than traditional toasting.

- Energy Efficiency - Plasma toasting consumes less energy compared to conventional heat methods, making it eco-friendly.

- Flavor Enhancement - The technique maintains garlic's sweetness and reduces bitterness by controlling temperature precisely.

- Safety and Speed - Plasma toasting reduces the risk of overheating and significantly shortens toasting time for rapid culinary use.

Flavor Profiles: Traditional Toasting vs Plasma Toasting for Garlic

Traditional toasting of garlic enhances its natural sweetness and imparts a rich, caramelized flavor through Maillard reactions, while plasma toasting preserves more of the garlic's fresh, pungent characteristics by using ionized gases at lower temperatures. The difference in heat application results in distinct flavor profiles that appeal to various culinary styles.

- Traditional Toasting - Utilizes dry heat to develop deep, roasted notes and mellow sharpness in garlic.

- Plasma Toasting - Employs ionized plasma to infuse garlic with subtle smoky flavors without significant browning.

- Flavor Intensity - Traditional methods yield a bolder, sweeter flavor, whereas plasma toasting maintains a fresher, more aromatic profile.

Choosing between these toasting methods depends on the desired balance of roasted richness versus vibrant garlic pungency in culinary applications.

Texture Differences in Garlic: Toasting vs Plasma Toasting

Traditional toasting of garlic transforms its texture by creating a crispy, golden exterior while maintaining a slightly chewy center. This method relies on direct heat, leading to a more uneven texture that enhances the depth of roasted flavors.

Plasma toasting offers a novel approach by using ionized gas to uniformly heat garlic cloves, resulting in a consistently tender texture without the typical dryness of conventional toasting. The plasma method preserves moisture better, producing a smoother and less brittle garlic that intensifies natural sweetness.

Nutritional Impact: Plasma Toasting Compared to Conventional Toasting

How does plasma toasting affect the nutritional content of garlic compared to conventional toasting? Plasma toasting preserves higher levels of allicin, the key bioactive compound responsible for garlic's health benefits, by reducing heat exposure time. Conventional toasting often degrades sensitive nutrients, leading to diminished antioxidant properties and lower overall nutritional value.

Time and Efficiency: Which Toasting Method is Faster for Garlic?

Plasma toasting significantly reduces the time required to toast garlic compared to traditional toasting methods, often completing the process within seconds. This method enhances efficiency by providing uniform heat distribution, preventing burning and ensuring consistent flavor. Traditional toasting can take several minutes, making plasma toasting a faster and more precise option for garlic preparation.

Equipment and Accessibility: Traditional vs Plasma Toasting

Traditional toasting of garlic uses simple, widely available equipment like pans or ovens, making it accessible for home cooks and small kitchens. Plasma toasting requires advanced, specialized devices that generate ionized gas, limiting its use primarily to industrial or experimental settings.

- Equipment Simplicity - Traditional toasting relies on basic kitchen tools, making it easy to set up and operate.

- Technology Requirements - Plasma toasting depends on high-tech plasma generators, requiring technical knowledge and maintenance.

- Accessibility - Traditional methods are cost-effective and suitable for everyday use, while plasma toasting remains less accessible due to high costs and complexity.

Culinary Applications: When to Use Each Method for Garlic

Toasting garlic with traditional methods enhances its nutty flavor and crisp texture, making it ideal for dishes where a subtle roasted note is desired. Plasma toasting, utilizing ionized gas, delivers a more uniform heat distribution, preserving garlic's aromatic compounds and reducing bitterness.

Use traditional toasting for recipes that benefit from a crunchy, caramelized garlic flavor, such as in pasta or roasted vegetables. Plasma toasting is preferred for delicate culinary applications where maintaining garlic's fresh, complex aroma is essential, like in fine sauces or garnishes.

Related Important Terms

Maillard Reaction Profile

Toasting garlic using traditional methods enhances the Maillard reaction by gradually developing complex flavor compounds and a rich brown crust, while plasma toasting accelerates this reaction through ionized gas exposure, producing a more intense and uniform caramelization. The Maillard reaction profile in plasma toasting yields distinct aromatic notes and heightened umami compared to conventional toasting, optimizing garlic's savory depth.

Plasma-Activated Aroma

Plasma toasting enhances garlic's flavor by generating plasma-activated aroma compounds that intensify its natural sweetness and reduce bitterness compared to traditional toasting methods. This innovative technique promotes Maillard reactions at lower temperatures, preserving garlic's nutritional value while delivering a more complex and aromatic profile.

Dielectric Barrier Discharge (DBD) Toasting

Dielectric Barrier Discharge (DBD) toasting provides a uniform and energy-efficient method for garlic toasting compared to traditional plasma toasting, as it prevents overheating and preserves garlic's natural flavor by generating non-thermal plasma at low temperatures. The DBD technique also enhances the antioxidant properties and aroma profile of toasted garlic through controlled reactive species interaction without causing combustion.

Reactive Oxygen Species Infusion

Toasting garlic with traditional methods enhances its flavor through mild heat, whereas plasma toasting infuses Reactive Oxygen Species (ROS) that can alter the chemical profile, intensifying antioxidant properties and potentially improving health benefits. The ROS infusion in plasma toasting promotes unique molecular changes in garlic, making it a novel technique compared to conventional thermal toasting.

Controlled Browning Index

Controlled Browning Index (CBI) is crucial in toasting garlic, with traditional toasting methods offering less precision compared to plasma toasting, which enables more accurate regulation of browning levels. Plasma toasting minimizes over-browning and preserves garlic's flavor integrity by maintaining optimal CBI values through controlled heat application.

Organosulfur Compound Preservation

Toasting garlic with traditional methods often leads to significant loss of organosulfur compounds, which are crucial for its health benefits and flavor profile, whereas plasma toasting preserves these compounds more effectively through controlled, low-temperature processing. Plasma toasting maintains the integrity of allicin and other sulfur-containing molecules, enhancing both the nutritional value and aromatic quality of garlic compared to conventional toasting techniques.

Enzyme Deactivation Rate

Toasting garlic using traditional methods typically achieves an enzyme deactivation rate of around 70-80%, preserving some raw flavor compounds, whereas plasma toasting accelerates this process, reaching enzyme deactivation rates above 95%, resulting in a more uniform flavor and enhanced shelf stability. Plasma toasting utilizes ionized gases to effectively deactivate alliinase enzymes, preventing enzymatic browning and preserving the garlic's aroma compared to conventional thermal toasting.

Nonthermal Plasma Flavor Boost

Nonthermal plasma toasting enhances garlic's flavor by generating reactive species that intensify aroma without heat damage, unlike traditional toasting methods that rely on thermal processes. This advanced technique preserves garlic's freshness and boosts its savory notes, delivering a superior taste experience.

Polyphenol Retention Score

Garlic toasted using traditional methods retains a moderate Polyphenol Retention Score, while plasma toasting significantly enhances this score by preserving higher levels of polyphenols due to its low-temperature and controlled environment. This advanced plasma technique minimizes degradation of bioactive compounds, ensuring superior antioxidant properties in the final toasted garlic product.

Toasting vs Plasma toasting for garlic. Infographic

cookingdiff.com

cookingdiff.com