Toasting coffee beans involves evenly heating them to develop flavor and aroma, often using traditional drum or hot air roasters that provide consistent and controlled temperature exposure. Sonic toasting, a newer technique, utilizes high-frequency sound waves to agitate the beans, enhancing heat transfer and potentially reducing roasting time while preserving delicate flavor compounds. Comparing both methods highlights sonic toasting's potential for improved efficiency and flavor retention against the reliability and established quality of conventional toasting.

Table of Comparison

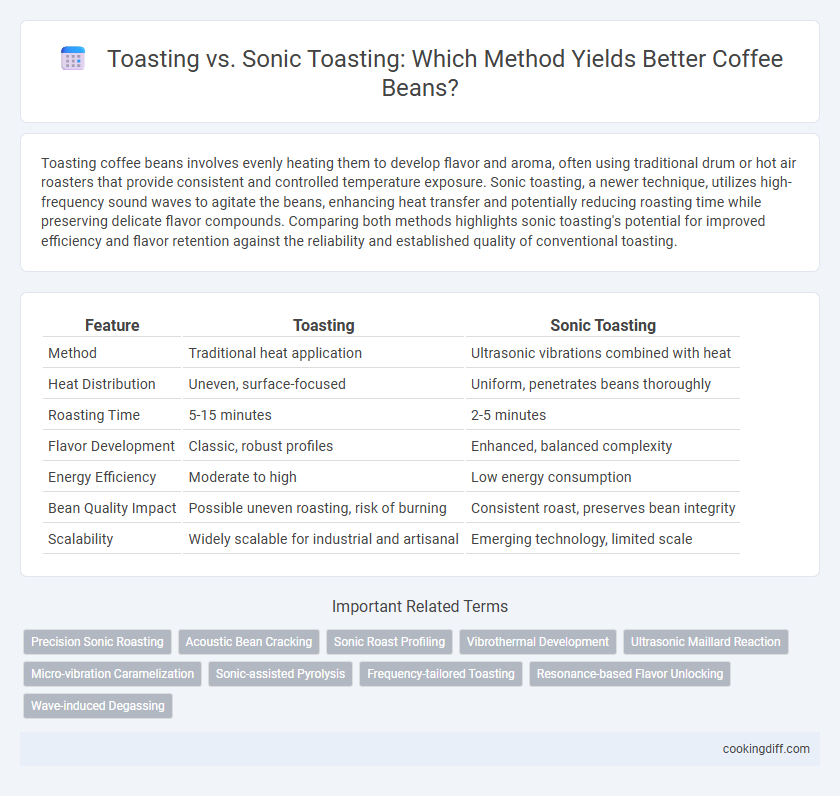

| Feature | Toasting | Sonic Toasting |

|---|---|---|

| Method | Traditional heat application | Ultrasonic vibrations combined with heat |

| Heat Distribution | Uneven, surface-focused | Uniform, penetrates beans thoroughly |

| Roasting Time | 5-15 minutes | 2-5 minutes |

| Flavor Development | Classic, robust profiles | Enhanced, balanced complexity |

| Energy Efficiency | Moderate to high | Low energy consumption |

| Bean Quality Impact | Possible uneven roasting, risk of burning | Consistent roast, preserves bean integrity |

| Scalability | Widely scalable for industrial and artisanal | Emerging technology, limited scale |

Introduction to Coffee Bean Toasting Methods

| Traditional toasting | uses direct heat sources like gas or electric roasters to gradually roast coffee beans, enhancing flavor profiles through Maillard reactions and caramelization. |

| Sonic toasting | employs ultrasonic waves to vibrate beans at high frequencies, aiming to evenly heat and roast beans more quickly while preserving aromatic compounds. |

| Comparison | traditional methods provide nuanced flavor development with slower roasting times, whereas sonic toasting offers efficiency and potential enhancement of coffee bean quality through uniform heat distribution. |

What is Traditional Toasting?

Traditional toasting involves heating coffee beans using direct contact with hot air or a drum roaster, allowing even heat distribution and gradual caramelization of sugars. This process enhances the beans' flavor profile by developing complex aromas and reducing acidity.

Unlike sonic toasting, traditional toasting relies on controlled temperature and time to achieve optimal roast levels, typically ranging from light to dark roast. It remains the preferred method for craft roasters seeking consistency and rich, balanced coffee flavors.

Sonic Toasting: An Innovative Approach

Sonic toasting utilizes high-frequency sound waves to gently heat coffee beans, preserving their natural flavors and aromatic compounds better than traditional toasting methods. This innovative approach reduces roasting times and minimizes the risk of burning, resulting in a smoother and more consistent coffee profile.

Unlike conventional toasting that relies on direct heat and often causes uneven roasting, sonic toasting evenly distributes energy at a microscopic level within the beans. The process enhances chemical reactions responsible for flavor development while maintaining bean integrity. Coffee producers adopting sonic technology report improved cup quality and greater control over roast profiles, leading to a superior sensory experience.

Key Differences Between Toasting and Sonic Toasting

What are the key differences between toasting and sonic toasting for coffee beans? Toasting uses traditional heat methods to develop flavor, while sonic toasting employs ultrasonic waves to evenly roast beans without high temperatures. Sonic toasting improves flavor retention and reduces roasting time compared to conventional toasting techniques.

Flavor Profiles: Toasted vs. Sonically Toasted Coffee Beans

Traditional toasting imparts a rich, caramelized flavor with deeper roasted notes, while sonic toasting preserves more of the coffee bean's original complexity and fruity undertones. Sonic toasting achieves a cleaner, more nuanced flavor profile by using sound waves to uniformly heat beans without over-roasting.

- Traditional Toasting - Produces strong, bold flavors with pronounced caramel and smoky characteristics.

- Sonic Toasting - Maintains delicate fruity and floral notes by minimizing heat-induced damage.

- Flavor Retention - Sonic methods reduce flavor degradation, enhancing aromatic clarity and balance.

Impact on Coffee Aroma and Acidity

Traditional toasting enhances coffee beans' aroma by developing complex Maillard reaction compounds, resulting in a rich, robust fragrance, while sonic toasting preserves more of the bean's natural volatile oils, offering a fresher, brighter aroma profile. Acidity tends to be more balanced and pronounced in sonic toasted beans due to gentler heat application, whereas traditional toasting can mellow acidity, producing a smoother, fuller body.

- Traditional toasting aroma development - Uses high heat to create deep, roasted notes through extensive Maillard reactions.

- Sonic toasting aroma preservation - Employs ultrasonic waves to maintain delicate volatile compounds for a fresher aroma.

- Acidity impact - Sonic toasting retains higher acidity levels, enhancing brightness compared to the mellow acidity from traditional toasting.

Equipment and Technology: Tools for Each Method

Traditional toasting of coffee beans utilizes drum roasters or fluid bed roasters that rely on direct heat and mechanical agitation to ensure even roasting. Sonic toasting employs ultrasonic waves to agitate and heat beans, enabling faster and more uniform roasting by penetrating the bean's interior at a microscopic level. Equipment for sonic toasting typically includes ultrasonic transducers and specialized chambers designed to optimize wave frequency and energy absorption for enhanced flavor development.

Efficiency and Consistency in Toasting Processes

Traditional toasting relies on direct heat transfer to roast coffee beans, often resulting in uneven heat distribution, which can affect the consistency of the roast profile. Sonic toasting uses ultrasonic waves to agitate the beans, promoting more uniform heat exposure and enhancing the efficiency of the roasting process.

Sonic toasting reduces roasting time and energy consumption by accelerating heat penetration, leading to lower operational costs and improved throughput. The precision of sonic toasting technology ensures consistent bean quality, minimizing batch variability and optimizing flavor profiles for specialty coffee production.

Sustainability and Energy Consumption Comparison

Traditional toasting methods for coffee beans often consume more energy due to prolonged heating cycles, while sonic toasting leverages high-frequency vibrations to reduce roasting time and energy use. Sonic toasting shows potential for lower carbon footprint and improved sustainability by minimizing fuel consumption and waste during the coffee roasting process.

- Energy efficiency - Sonic toasting reduces roasting duration by up to 30%, significantly lowering electricity consumption.

- Carbon emissions - Conventional roasting emits higher CO2 levels compared to the cleaner sonic process.

- Resource use - Sonic toasting uses less fuel and produces fewer byproducts, enhancing overall sustainability.

Switching to sonic toasting technology can contribute to eco-friendly coffee production with measurable reductions in energy consumption and environmental impact.

Related Important Terms

Precision Sonic Roasting

Precision Sonic Roasting uses high-frequency sound waves to uniformly heat coffee beans, resulting in more precise control over roast profiles compared to traditional toasting methods. This technique enhances flavor development and consistency by minimizing uneven heating and preserving the beans' aromatic compounds.

Acoustic Bean Cracking

Acoustic bean cracking in traditional toasting produces distinct sound patterns that indicate optimal roast levels for coffee beans, enhancing control over flavor development. Sonic toasting utilizes high-frequency sound waves to uniformly agitate beans, improving roast consistency by minimizing over-cracking and preserving aromatic compounds.

Sonic Roast Profiling

Sonic roast profiling uses high-frequency sound waves to achieve precise, uniform heat distribution during coffee bean toasting, resulting in enhanced aroma and flavor complexity compared to traditional toasting methods. This technique allows for better control of roast levels, preserving the beans' intrinsic qualities while reducing the risk of scorching or uneven roasting.

Vibrothermal Development

Vibrothermal development in toasting enhances coffee bean flavor by combining precise vibration with controlled thermal energy, ensuring uniform heat distribution and preventing scorching. Unlike sonic toasting, which relies on ultrasonic waves without heat control, vibrothermal methods optimize aroma and taste through consistent agitation and temperature management.

Ultrasonic Maillard Reaction

Ultrasonic Maillard reaction during sonic toasting enhances flavor development in coffee beans by accelerating amino acid and sugar interactions, resulting in richer aroma profiles compared to traditional toasting. This method promotes uniform heat distribution and shorter roasting times, preserving bean quality and maximizing antioxidant retention.

Micro-vibration Caramelization

Micro-vibration caramelization in sonic toasting uses high-frequency vibrations to evenly heat coffee beans, enhancing complex flavor development and preserving aroma better than traditional toasting methods. This technique promotes uniform caramelization at a molecular level, resulting in a richer, more nuanced coffee profile with improved sweetness and reduced bitterness.

Sonic-assisted Pyrolysis

Sonic-assisted pyrolysis enhances the toasting process of coffee beans by utilizing ultrasonic waves to promote uniform heat distribution and accelerate the breakdown of organic compounds, resulting in more consistent flavor profiles and reduced roasting times. Unlike traditional toasting, sonic toasting improves the extraction of aromatic compounds and minimizes thermal degradation, optimizing the quality and sensory characteristics of the final coffee product.

Frequency-tailored Toasting

Frequency-tailored toasting leverages precise acoustic frequencies to uniformly heat coffee beans, enhancing flavor development by targeting the beans' unique thermal properties. This method contrasts with conventional sonic toasting by optimizing vibration frequency for consistent heat distribution, resulting in a more balanced roast and improved aroma complexity.

Resonance-based Flavor Unlocking

Resonance-based flavor unlocking in sonic toasting enhances coffee beans by using precise acoustic vibrations to evenly heat and open cellular structures, preserving aromatic compounds and intensifying flavor complexity compared to traditional toasting methods. This technology enables consistent bean transformation through controlled resonance frequencies, resulting in richer, more nuanced coffee profiles and reduced risk of scorching.

Toasting vs Sonic toasting for coffee beans. Infographic

cookingdiff.com

cookingdiff.com