Toasting grains enhances flavor by applying dry heat that causes Maillard reactions, creating a rich, nutty taste without breaking down the grain's structure. Pyrolysis involves higher temperatures that decompose organic material, resulting in charred flavors and loss of nutritional content. Choosing toasting over pyrolysis preserves the grain's integrity while developing desirable aromas and textures.

Table of Comparison

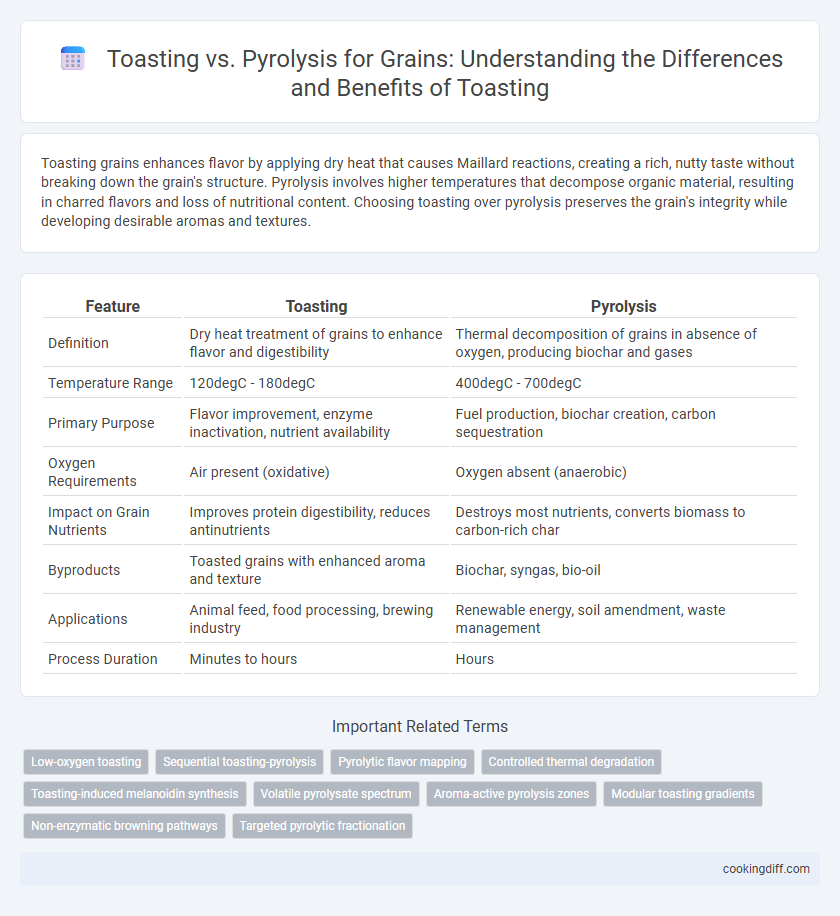

| Feature | Toasting | Pyrolysis |

|---|---|---|

| Definition | Dry heat treatment of grains to enhance flavor and digestibility | Thermal decomposition of grains in absence of oxygen, producing biochar and gases |

| Temperature Range | 120degC - 180degC | 400degC - 700degC |

| Primary Purpose | Flavor improvement, enzyme inactivation, nutrient availability | Fuel production, biochar creation, carbon sequestration |

| Oxygen Requirements | Air present (oxidative) | Oxygen absent (anaerobic) |

| Impact on Grain Nutrients | Improves protein digestibility, reduces antinutrients | Destroys most nutrients, converts biomass to carbon-rich char |

| Byproducts | Toasted grains with enhanced aroma and texture | Biochar, syngas, bio-oil |

| Applications | Animal feed, food processing, brewing industry | Renewable energy, soil amendment, waste management |

| Process Duration | Minutes to hours | Hours |

Understanding Toasting and Pyrolysis: Key Differences

Toasting and pyrolysis are thermal processing methods used for grains, each affecting flavor and chemical composition differently. Toasting involves heating grains at moderate temperatures to develop flavor and aroma without significant chemical breakdown, while pyrolysis requires higher temperatures leading to decomposition and the creation of char and volatiles.

- Toasting - Heat is applied at temperatures typically between 120-200degC to enhance flavor and preserve nutritional value.

- Pyrolysis - Grains are subjected to temperatures above 300degC causing thermal decomposition and the formation of biochar and gases.

- Flavor Impact - Toasting produces nutty, toasted notes whereas pyrolysis generates smoky, burnt characteristics due to chemical transformation.

How Toasting Impacts Grain Flavor Profiles

Toasting grains enhances their flavor profiles by promoting Maillard reactions, which develop complex, nutty, and caramelized notes. This process also reduces moisture content, intensifying the grain's natural taste and creating a crisp texture.

Unlike pyrolysis, which involves thermal decomposition at higher temperatures and can introduce smoky or burnt flavors, toasting preserves the grain's inherent characteristics while adding depth. The controlled heat application during toasting ensures a balance of flavor development without compromising the grain's nutritional quality.

Pyrolysis: The Science Behind Grain Transformation

Pyrolysis involves the thermal decomposition of grains in an oxygen-limited environment, causing chemical changes that produce smoky flavors and enhance aroma complexity. This process alters the grain's molecular structure more deeply than traditional toasting, resulting in distinct taste profiles for brewing and food applications.

- Thermal Breakdown - Pyrolysis breaks down carbohydrates and proteins into simpler compounds, intensifying flavor development.

- Oxygen-Limited Environment - The absence of oxygen prevents combustion, allowing controlled chemical reactions that create unique flavor compounds.

- Flavor Complexity - Pyrolysis generates diverse volatile compounds like phenols and aldehydes, contributing to rich, smoky notes.

Understanding pyrolysis offers insight into optimizing grain processing for enhanced sensory characteristics beyond conventional toasting methods.

Comparing Nutritional Effects: Toasting vs Pyrolysis

Toasting grains enhances flavor while preserving essential nutrients such as vitamins and antioxidants. In contrast, pyrolysis involves higher temperatures that can degrade nutritional quality but increase bioavailability of some compounds.

- Toasting - Retains more vitamins and antioxidants compared to pyrolysis due to milder heating.

- Pyrolysis - Breaks down complex molecules, improving digestibility but potentially reducing nutrient content.

- Nutritional Impact - Toasting offers better preservation of heat-sensitive nutrients, whereas pyrolysis may produce beneficial bioactive compounds.

Equipment and Methods for Toasting and Pyrolysis

Toasting equipment typically includes rotary drum roasters and fluidized bed roasters designed for controlled heat application and even browning of grains. Pyrolysis systems use high-temperature reactors that decompose organic material in the absence of oxygen, producing biochar and volatile byproducts. Toasting methods emphasize precise temperature control (usually 100-200degC) to develop flavor, while pyrolysis occurs at much higher temperatures (above 400degC) for chemical transformation.

Flavor Development: Toasted Grains vs Pyrolyzed Grains

Toasting grains enhances flavor development by applying dry heat that promotes Maillard reactions, resulting in nutty, caramel-like notes without burning. Pyrolysis involves thermal decomposition at higher temperatures in the absence of oxygen, often producing bitter and smoky flavors due to charring and chemical breakdown. The controlled heat in toasting preserves desirable aromatic compounds, making it superior for flavor refinement compared to the harsher, more intense taste created by pyrolysis.

Safety Considerations in Toasting and Pyrolysis

Toasting grains is generally safer than pyrolysis due to lower temperatures, reducing the risk of combustion and harmful emissions. Pyrolysis involves high heat in oxygen-limited conditions, increasing the potential hazards such as toxic gas release and fire risk.

Safety protocols in toasting primarily focus on temperature control and ventilation to prevent overheating and smoke buildup. Pyrolysis requires stringent monitoring of oxygen levels, temperature, and gas management to avoid explosive atmospheres and toxic byproducts. Proper equipment design and regular maintenance are critical for minimizing risks in both processes.

Industrial Applications: Which Process Suits Your Needs?

Toasting involves applying dry heat to grains, enhancing flavor and aroma through Maillard reactions without significant chemical alteration, making it ideal for food industries focused on taste and texture improvement. Pyrolysis, on the other hand, thermally decomposes grains in the absence of oxygen, producing biochar, bio-oil, and syngas, which suits energy and soil amendment applications in agriculture and biofuel sectors.

Industrially, toasting is preferred for cereal, snack, and coffee production due to its ability to preserve nutritional content and enhance sensory appeal. Pyrolysis fits better with waste management and renewable energy strategies, enabling grain residue valorization but with less emphasis on edible quality.

Environmental Impact: Toasting Compared to Pyrolysis

| Process | Environmental Impact |

|---|---|

| Toasting | Produces lower emissions of greenhouse gases and volatile organic compounds (VOCs) due to controlled heating at moderate temperatures, minimizing energy consumption and reducing atmospheric pollutants. |

| Pyrolysis | Generates significant amounts of particulate matter, methane, and carbon monoxide from high-temperature decomposition of grains, increasing environmental pollution and energy demand despite potential biochar benefits. |

Related Important Terms

Low-oxygen toasting

Low-oxygen toasting preserves essential nutrients and enhances flavor complexity in grains by minimizing oxidative damage compared to pyrolysis, which involves higher temperatures that can degrade nutrient profiles. This controlled environment allows for gentle Maillard reactions without producing harmful byproducts, making low-oxygen toasting a superior method for maintaining grain quality and nutritional value.

Sequential toasting-pyrolysis

Sequential toasting-pyrolysis enhances flavor development and nutrient retention in grains by combining toasting's Maillard reaction-driven browning with pyrolysis's thermal decomposition process. This method optimizes grain texture and aroma while maintaining high energy efficiency and reducing harmful byproducts compared to standalone toasting or pyrolysis techniques.

Pyrolytic flavor mapping

Pyrolysis generates complex Maillard reaction products and volatile compounds that create intense, smoky, and roasted flavor profiles in grains, distinct from the milder, nutty notes produced by traditional toasting. Detailed pyrolytic flavor mapping reveals specific aromatic compounds such as furans, phenols, and aldehydes that contribute to the depth and richness of flavors not achievable through simple thermal toasting.

Controlled thermal degradation

Controlled thermal degradation in toasting involves precise temperature regulation to enhance flavor and color in grains without breaking down nutritional components, whereas pyrolysis subjects grains to higher temperatures causing extensive chemical decomposition and producing char and volatile compounds. Toasting preserves the structural integrity and desirable sensory attributes, making it suitable for food processing, while pyrolysis is typically used for biofuel production and chemical extraction from biomass.

Toasting-induced melanoidin synthesis

Toasting grains activates the Maillard reaction, leading to the synthesis of melanoidins that enhance flavor, color, and antioxidant properties, unlike pyrolysis which primarily causes thermal decomposition without forming these complex compounds. This controlled heat exposure during toasting preserves grain integrity while promoting beneficial melanoidin formation, crucial for improving sensory and nutritional quality.

Volatile pyrolysate spectrum

Toasting of grains produces a narrower volatile pyrolysate spectrum dominated by Maillard reaction products such as pyrazines and furans, enhancing flavor complexity and aroma. Pyrolysis generates a broader range of volatile compounds including phenols, aldehydes, and organic acids, which can contribute to off-flavors and increased bitterness in grain-based products.

Aroma-active pyrolysis zones

Toasting enhances grains by gently heating them to develop complex aroma-active compounds in the Maillard reaction zone, which imparts nutty and caramelized notes without degrading nutritional value. Pyrolysis exceeds these temperatures, creating distinct aroma-active pyrolysis zones rich in smoky and roasted flavors but risks producing undesirable bitter or burnt notes.

Modular toasting gradients

Modular toasting gradients enable precise control over temperature and time, optimizing flavor development in grains while minimizing undesirable compounds formed in pyrolysis. Unlike pyrolysis, which involves thermal decomposition without oxygen leading to charring, toasting uses controlled heat exposure promoting Maillard reactions and enhancing aroma profiles in grains.

Non-enzymatic browning pathways

Toasting of grains primarily induces Maillard reactions, a non-enzymatic browning pathway involving amino acids and reducing sugars, enhancing flavor and color without significant protein degradation. Pyrolysis, in contrast, occurs at higher temperatures causing thermal decomposition and caramelization, producing more complex volatile compounds but also potential nutrient loss.

Toasting vs Pyrolysis for grains. Infographic

cookingdiff.com

cookingdiff.com