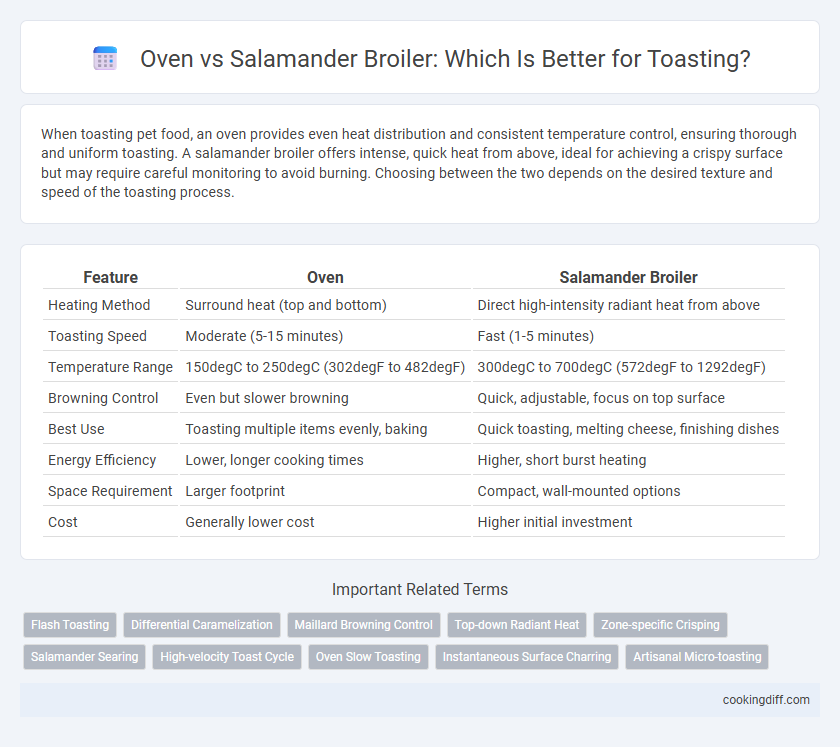

When toasting pet food, an oven provides even heat distribution and consistent temperature control, ensuring thorough and uniform toasting. A salamander broiler offers intense, quick heat from above, ideal for achieving a crispy surface but may require careful monitoring to avoid burning. Choosing between the two depends on the desired texture and speed of the toasting process.

Table of Comparison

| Feature | Oven | Salamander Broiler |

|---|---|---|

| Heating Method | Surround heat (top and bottom) | Direct high-intensity radiant heat from above |

| Toasting Speed | Moderate (5-15 minutes) | Fast (1-5 minutes) |

| Temperature Range | 150degC to 250degC (302degF to 482degF) | 300degC to 700degC (572degF to 1292degF) |

| Browning Control | Even but slower browning | Quick, adjustable, focus on top surface |

| Best Use | Toasting multiple items evenly, baking | Quick toasting, melting cheese, finishing dishes |

| Energy Efficiency | Lower, longer cooking times | Higher, short burst heating |

| Space Requirement | Larger footprint | Compact, wall-mounted options |

| Cost | Generally lower cost | Higher initial investment |

Introduction to Toasting: Oven vs Salamander Broiler

What are the key differences between using an oven and a salamander broiler for toasting? Ovens provide even, consistent heat ideal for larger batches and slower browning, while salamander broilers deliver intense, direct heat for rapid toasting and crisping. Choosing between them depends on the desired texture and speed of toasting.

Key Differences Between Oven and Salamander Broiler

The oven toasts food through surrounding heat, ensuring even cooking with adjustable temperature controls, ideal for baking and broader cooking tasks. It takes longer to brown surfaces due to indirect heat distribution compared to a salamander broiler.

The salamander broiler uses intense direct radiant heat from above, enabling rapid browning and crisping, perfect for finishing dishes like gratins or melting cheese. Its high-temperature broiling makes it less versatile but faster for precise toasting tasks.

Toasting Efficiency: Speed and Consistency

Salamander broilers offer superior toasting efficiency with rapid, intense heat allowing for faster browning and crisping compared to traditional ovens. Ovens provide more consistent heat distribution but typically require longer to achieve the desired toast level.

- Salamander rapid heating - Delivers intense top-down heat for quick, uniform toasting in seconds.

- Oven consistency - Circulates heat evenly around food, ensuring steady browning but at slower speeds.

- Energy efficiency - Salamanders consume less energy per toasting cycle due to shorter operation times.

Choosing a salamander broiler maximizes speed and crispness, ideal for high-volume toasting scenarios.

Heat Distribution: Infrared vs Conventional

Salamander broilers use infrared heat for rapid, intense toasting with precise heat distribution focused on the surface. Conventional ovens provide indirect, ambient heat that surrounds the food, enabling more even cooking but slower toasting.

- Infrared Heat - Delivers concentrated energy that quickly browns and crisps the top layer without penetrating deeply.

- Conventional Heat - Circulates warm air evenly around the food for uniform heat penetration and consistent texture.

- Heat Distribution - Infrared targets the surface efficiently, whereas conventional ovens rely on ambient heat flow to toast thoroughly.

Versatility in Toasting Applications

The oven offers versatility in toasting by providing consistent, even heat suitable for both quick browning and slower, gentler toasting processes. It accommodates a wide variety of bread types and thicknesses, making it ideal for diverse toasting applications.

The salamander broiler excels in high-temperature, rapid toasting with precise control, perfect for finishing dishes and achieving a crispy surface. It allows chefs to monitor the toasting process closely due to its open design, enhancing the quality of toasted items such as open-faced sandwiches and artisan bread. Its compact size also makes it a space-efficient choice for kitchens focused on specialized toasting tasks.

Energy Consumption and Cost Comparison

| Appliance | Energy Consumption (kWh per hour) | Average Energy Cost (USD per hour) |

|---|---|---|

| Oven | 2.5 - 3.0 | 0.30 - 0.36 |

| Salamander Broiler | 1.2 - 1.5 | 0.14 - 0.18 |

The salamander broiler uses significantly less energy than a conventional oven, leading to lower operational costs during toasting tasks. Energy-efficient heating elements and rapid heat-up times make salamander broilers ideal for fast, cost-effective toasting in commercial kitchens. Ovens consume nearly twice the energy, increasing utility expenses for prolonged toasting or baking processes.

Space Requirements and Kitchen Compatibility

Ovens require significantly more space compared to salamander broilers, often needing a dedicated area due to their larger size. Salamander broilers are compact and wall-mountable, making them ideal for kitchens with limited space.

Ovens integrate well in kitchens designed for multi-use, accommodating large batches of toasting alongside other cooking activities. Salamander broilers offer superior kitchen compatibility for quick, high-heat toasting without occupying valuable countertop or floor space.

User Control and Precision in Toasting

Oven toasting offers consistent heat distribution, allowing users to toast multiple items evenly with adjustable temperature settings for precise control. Salamander broilers provide intense, direct heat ideal for quick toasting and browning, giving users immediate visual feedback to customize the process. The choice between them hinges on desired control over heat intensity and speed, with ovens favoring gradual, uniform toasting and salamanders enabling rapid, high-precision results.

Maintenance and Cleaning Considerations

Oven toasters require regular cleaning of crumb trays and interior surfaces to prevent buildup and ensure consistent heat distribution. Salamander broilers, designed for intense direct heat, need frequent cleaning of broiler elements and grease traps to avoid flare-ups and maintain optimal performance. Proper maintenance for both appliances extends their lifespan and improves food safety by minimizing residue and bacteria accumulation.

Related Important Terms

Flash Toasting

Flash toasting with a salamander broiler delivers intense, direct radiant heat that crisps surfaces rapidly without drying interiors, making it ideal for finishing dishes or toasting bread with precision. Ovens provide more even, slower heat distribution suitable for thorough toasting but lack the immediate high-temperature burst essential for flash toasting techniques.

Differential Caramelization

Oven toasting provides gradual, even heat ideal for consistent caramelization across bread surfaces, enhancing Maillard reactions uniformly. Salamander broilers emit intense, direct heat, creating rapid differential caramelization that intensifies texture contrast with crisp edges and a softer interior.

Maillard Browning Control

Oven toasting provides even heat distribution, allowing gradual Maillard browning for consistent color and flavor development, while salamander broilers deliver intense, direct heat that accelerates surface browning but requires careful timing to avoid burning. Controlling temperature and exposure time in ovens enables precise Maillard reaction optimization, whereas salamanders offer rapid toasting ideal for crisp crusts but less uniform browning.

Top-down Radiant Heat

Oven toasting relies on indirect, even radiant heat that surrounds the food, providing consistent browning but with slower top-down heat intensity compared to a salamander broiler. Salamander broilers deliver intense top-down radiant heat from above, enabling rapid surface crisping and caramelization ideal for precise toasting and finishing dishes quickly.

Zone-specific Crisping

Ovens provide even, zone-specific heat ideal for thorough toasting and uniform browning across multiple items simultaneously, while salamander broilers deliver intense, localized heat perfect for rapid, top-down crisping and finishing touches. For precise control over crust texture and color, combining oven baking with salamander broiling optimizes both internal warmth and external crispiness.

Salamander Searing

Salamander broilers provide intense, radiant heat ideal for rapid searing and toasting, achieving a perfectly caramelized crust without drying the interior. Unlike conventional ovens, salamanders allow precise control over high temperatures, making them essential for professional kitchens focused on superior toast texture and flavor.

High-velocity Toast Cycle

Oven toasting relies on ambient heat, often producing slower, less even results compared to the high-velocity toast cycle of a salamander broiler, which uses intense, direct infrared heat for rapid, uniform browning. The salamander's concentrated heat accelerates the Maillard reaction, achieving crisp textures and golden finishes in a fraction of the time an oven requires.

Oven Slow Toasting

Oven slow toasting ensures even heat distribution, preserving bread's moisture while achieving a consistent golden crust, unlike the intense direct heat of a salamander broiler that toasts quickly but risks uneven browning. Slow toasting in an oven enhances flavor development through gradual caramelization, making it ideal for delicate breads and artisan toasts.

Instantaneous Surface Charring

Oven toasting offers even heat distribution but lacks the rapid, intense heat required for instantaneous surface charring, resulting in slower browning. Salamander broilers deliver immediate high-temperature exposure, creating quick, crisp surface charring ideal for precise toasting results.

Oven vs Salamander broiler for toasting. Infographic

cookingdiff.com

cookingdiff.com