Toasting sandwiches using traditional methods relies on direct heat, creating a crispy, evenly browned exterior while preserving the soft interior. Infrared toasting, by contrast, uses radiant energy to heat the sandwich quickly and efficiently, resulting in faster cooking times and enhanced flavor retention without drying out the bread. Infrared toasting also provides more precise temperature control, reducing the risk of burning and ensuring consistent results every time.

Table of Comparison

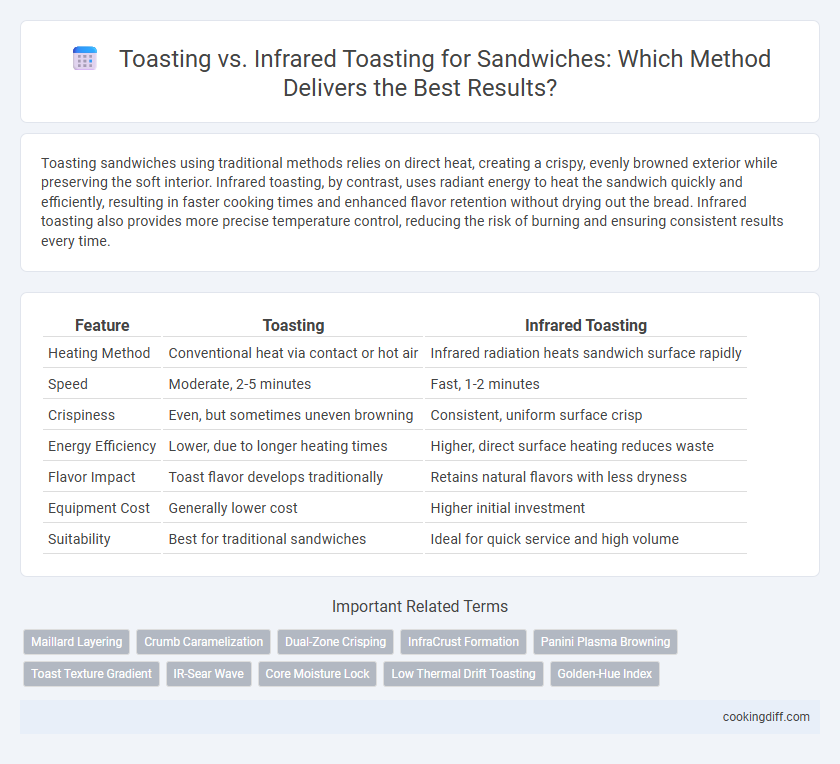

| Feature | Toasting | Infrared Toasting |

|---|---|---|

| Heating Method | Conventional heat via contact or hot air | Infrared radiation heats sandwich surface rapidly |

| Speed | Moderate, 2-5 minutes | Fast, 1-2 minutes |

| Crispiness | Even, but sometimes uneven browning | Consistent, uniform surface crisp |

| Energy Efficiency | Lower, due to longer heating times | Higher, direct surface heating reduces waste |

| Flavor Impact | Toast flavor develops traditionally | Retains natural flavors with less dryness |

| Equipment Cost | Generally lower cost | Higher initial investment |

| Suitability | Best for traditional sandwiches | Ideal for quick service and high volume |

Introduction to Toasting Methods for Sandwiches

Toasting sandwiches enhances flavor and texture by applying heat to bread and fillings. Traditional toasting uses direct heat, often via a toaster or pan, while infrared toasting employs infrared radiation for faster, more even heating.

Infrared toasting penetrates food more efficiently, reducing toasting time and preserving moisture within sandwich fillings. This method minimizes surface burning and provides consistent browning, ideal for delicate ingredients. Choosing between traditional and infrared toasting depends on desired texture, speed, and flavor retention for sandwiches.

What is Traditional Toasting?

Traditional toasting uses direct heat from electric or gas elements to brown the bread's surface, creating a crisp texture through Maillard reaction. This method typically involves placing the sandwich in a toaster or oven until the desired toast level is achieved.

Heat transfer occurs via conduction and convection, ensuring even toasting on both sides of the sandwich. It enhances flavor and texture but can sometimes dry out the sandwich filling if over-toasted.

Understanding Infrared Toasting Technology

Infrared toasting technology uses radiant heat to cook sandwiches evenly without direct contact, resulting in a crisp exterior and warm interior. Unlike traditional toasting methods that rely on convection or conduction, infrared toasters emit specific wavelengths that penetrate the sandwich surface quickly. This technique enhances flavor retention and reduces toasting time, making it an efficient alternative for sandwich preparation.

Heat Distribution: Conventional vs Infrared

| Heat Distribution | Conventional Toasting | Infrared Toasting |

|---|---|---|

| Heat Source | Uses electric or gas elements that heat the air surrounding the sandwich | Employs infrared radiation directly targeting the sandwich surface for quicker heating |

| Heat Penetration | Relies on convection and conduction for gradual heat penetration throughout the sandwich layers | Delivers intense surface heat that quickly cooks the sandwich exterior while maintaining moisture inside |

| Temperature Consistency | Heat distribution can be uneven, often requiring flipping or repositioning for uniform toasting | Provides more consistent heat distribution with minimal hot spots, resulting in even browning |

Speed and Efficiency: Which Toasts Faster?

Which method toasts sandwiches faster: traditional toasting or infrared toasting? Infrared toasting uses radiant heat to penetrate the sandwich quickly, significantly reducing toasting time compared to conventional methods. This technology enhances efficiency by delivering consistent heat without the need for prolonged exposure, making it ideal for busy kitchens.

Texture and Flavor Differences in Sandwiches

Traditional toasting uses direct heat to create a crispy, browned exterior with a warm, soft interior, enhancing the sandwich's toasted flavor. Infrared toasting employs radiant heat for rapid, even cooking that preserves moisture, resulting in a tender texture and intensified flavors.

- Traditional Toasting Texture - Produces a crunchy crust while maintaining a soft inside due to slower, conduction-based heating.

- Infrared Toasting Flavor - Enhances the natural flavors by sealing in juices quickly through radiant heat.

- Texture Contrast - Infrared toasting yields a more uniform texture, whereas traditional toasting creates distinct crispy and soft layers.

Energy Consumption and Cost Comparison

Infrared toasting technology consumes significantly less energy than traditional toasting methods by directly heating the sandwich's surface, resulting in faster toasting times and lower electricity usage. Studies show infrared toasters can reduce energy consumption by up to 30%, translating into notable cost savings over time.

Traditional toasters often have longer heating cycles, leading to increased power consumption and higher operational costs compared to infrared units. The initial investment in infrared toasting equipment may be higher, but the reduced energy bills and improved efficiency provide a better return on investment.

Versatility: Types of Sandwiches Each Method Supports

Traditional toasting methods accommodate a wide variety of sandwich types, from paninis to grilled cheese, offering control over browning and texture. Infrared toasting excels in evenly heating sandwiches with delicate or diverse ingredients, preserving moisture while achieving a crisp exterior.

- Grilled Cheese and Paninis - Traditional toasting supports thick, layered sandwiches by allowing gradual heat penetration and customizable browning.

- Delicate Ingredients - Infrared toasting is ideal for delicate fillings like fresh vegetables and soft cheeses, preventing overcooking and dryness.

- Mixed Textures - Infrared toasting evenly crisps bread while gently warming fillings, enhancing sandwiches with varied textures.

Choosing between methods depends on the sandwich type and desired texture for optimal versatility.

Maintenance and Durability of Toasting Appliances

Traditional toasting appliances generally require more frequent cleaning and maintenance due to crumbs and residue buildup, potentially impacting their longevity. Infrared toasting devices offer enhanced durability with fewer moving parts and easier maintenance, prolonging appliance lifespan.

- Maintenance frequency - Traditional toasters need regular crumb removal and surface cleaning to prevent malfunction.

- Durability - Infrared toasters often use robust components that resist wear and require less upkeep.

- Ease of cleaning - Infrared toasting surfaces tend to be smoother and less prone to residue accumulation, simplifying maintenance.

Related Important Terms

Maillard Layering

Toasting sandwiches develops the Maillard reaction, creating a rich, flavorful crust through direct heat that caramelizes surface sugars and proteins. Infrared toasting enhances Maillard layering by delivering intense, penetrating heat that accelerates this browning process without drying the bread, producing a crisp exterior while preserving interior moisture.

Crumb Caramelization

Toasting sandwiches using traditional methods promotes even crumb caramelization through direct heat contact, enhancing flavor by Maillard reaction development on the bread's surface. Infrared toasting, powered by radiant heat, offers rapid caramelization with precise temperature control but may result in uneven crumb texture due to localized heating variations.

Dual-Zone Crisping

Dual-zone crisping technology in toasting sandwiches ensures even heat distribution by separately controlling top and bottom heating elements, preventing soggy interiors and burnt exteriors. Infrared toasting uses radiant heat for rapid surface browning but may lack the precise temperature control necessary for consistent dual-zone crisping results.

InfraCrust Formation

Infrared toasting enhances infrared crust (InfraCrust) formation by using targeted radiant heat, creating a crispier, evenly browned sandwich surface compared to traditional toasting methods that rely on convection or contact heat. This InfraCrust results from rapid Maillard reactions triggered at higher surface temperatures, improving texture and flavor without overcooking the interior.

Panini Plasma Browning

Panini plasma browning uses a focused plasma arc to achieve rapid, uniform toasting with deeper Maillard reaction effects compared to traditional infrared toasting, resulting in enhanced flavor and crisp texture. Infrared toasting relies on radiant heat that can lead to uneven browning and less pronounced crust development on sandwiches.

Toast Texture Gradient

Toasting creates a uniform golden-brown crust with a consistent warmth gradient, enhancing the sandwich's overall texture by producing a slightly crisp exterior and soft interior. Infrared toasting, by contrast, generates a sharper texture gradient with more intense surface browning and rapid heat penetration, resulting in a crunchier crust while preserving moistness inside.

IR-Sear Wave

Infrared toasting using IR-Sear Wave technology provides faster, more even heat distribution compared to traditional toasting, enhancing sandwich crispiness without drying out fillings. This method penetrates food surfaces efficiently, resulting in superior browning and energy savings during sandwich preparation.

Core Moisture Lock

Infrared toasting technology excels in preserving core moisture within sandwiches by evenly distributing heat, preventing dryness and maintaining optimal texture. Traditional toasting methods often cause uneven heating, leading to moisture loss and a less satisfying bite.

Low Thermal Drift Toasting

Low thermal drift toasting ensures consistent heat distribution, preventing uneven cooking and preserving sandwich texture and flavor. Infrared toasting, while fast, often struggles with thermal drift, leading to hotspots that can overcook or underheat sandwich components.

Toasting vs Infrared Toasting for sandwiches. Infographic

cookingdiff.com

cookingdiff.com