Toasting bread primarily involves the Maillard reaction, a chemical process where heat causes amino acids and reducing sugars to react, producing complex flavors and a browned crust. Unlike simple caramelization that only affects sugars, Maillardization enhances both taste and aroma by creating a range of flavor compounds essential for toasted bread's distinctive profile. The depth of browning and flavor intensity depends on factors like temperature and time, making precise control key to achieving the perfect toast.

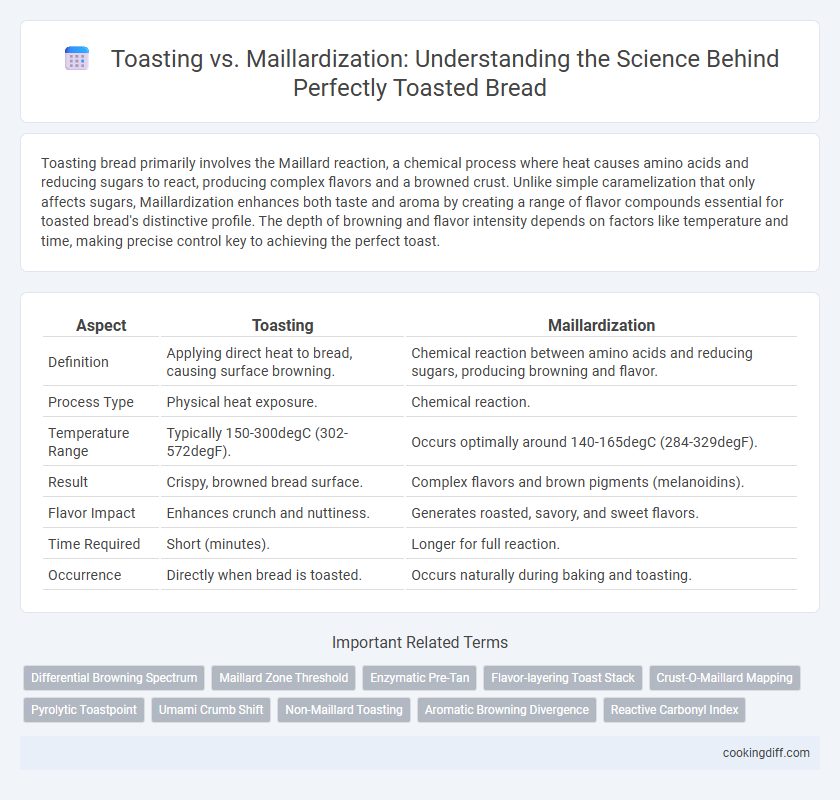

Table of Comparison

| Aspect | Toasting | Maillardization |

|---|---|---|

| Definition | Applying direct heat to bread, causing surface browning. | Chemical reaction between amino acids and reducing sugars, producing browning and flavor. |

| Process Type | Physical heat exposure. | Chemical reaction. |

| Temperature Range | Typically 150-300degC (302-572degF). | Occurs optimally around 140-165degC (284-329degF). |

| Result | Crispy, browned bread surface. | Complex flavors and brown pigments (melanoidins). |

| Flavor Impact | Enhances crunch and nuttiness. | Generates roasted, savory, and sweet flavors. |

| Time Required | Short (minutes). | Longer for full reaction. |

| Occurrence | Directly when bread is toasted. | Occurs naturally during baking and toasting. |

Understanding Toasting and Maillardization

Toasting bread involves applying dry heat that caramelizes sugars and enhances flavor, while Maillardization refers to the chemical reaction between amino acids and reducing sugars that create complex browning and aroma compounds. Understanding the distinction helps in optimizing bread texture and taste during preparation.

- Toasting - Uses direct heat to brown the surface and alter moisture content, producing crispness.

- Maillardization - A non-enzymatic browning reaction responsible for developing savory flavors and color.

- Bread Texture Impact - Toasting enhances crunchiness, while Maillardization contributes to flavor complexity without solely relying on caramelization.

The Science Behind Toasting Bread

Toasting bread primarily involves the Maillard reaction, a chemical process where amino acids and reducing sugars react under heat to develop complex flavors and brown coloration. This reaction enhances the aroma and taste, differentiating toasted bread from plain bread.

The Maillard reaction is temperature-dependent, typically occurring between 140degC and 165degC, causing the crust of the bread to become crispy while maintaining a soft interior. Caramelization also plays a minor role when sugars are heated beyond 160degC, contributing to browning and sweetness. Both processes together create the characteristic texture and flavor profile unique to toasted bread.

What is Maillardization?

Maillardization, or the Maillard reaction, is a chemical process between amino acids and reducing sugars that occurs when bread is heated, contributing to its flavor and browning. This reaction typically begins at temperatures above 140degC (284degF) and is responsible for the complex, savory notes in toasted bread. Unlike simple toasting, which primarily dries the bread, Maillardization enhances aroma, taste, and crust texture through this non-enzymatic browning mechanism.

Key Differences: Toasting vs. Maillardization

What are the key differences between toasting and Maillardization in bread preparation? Toasting is the process of browning bread through dry heat, primarily enhancing texture and flavor by evaporating moisture, while Maillardization is a complex chemical reaction between amino acids and reducing sugars that occurs during toasting, producing distinct brown color and rich flavor compounds. Maillardization specifically contributes to the savory and aromatic qualities in toasted bread, distinguishing it from simple heat-induced crisping.

How Toasting Affects Bread’s Texture and Flavor

Toasting bread causes moisture to evaporate, resulting in a crisp texture that contrasts with the soft interior. The heat triggers Maillardization, which develops complex flavors and rich browning on the crust.

- Texture Transformation - Toasting converts the bread's surface from soft to crunchy by driving off internal moisture.

- Flavor Development - Maillard reaction during toasting creates aromatic compounds responsible for toasted bread's distinctive, savory taste.

- Visual Appeal - The golden-brown coloration of toasted bread is a direct result of chemical reactions that enhance sensory experience.

Maillard Reaction: Impact on Bread Crust and Aroma

The Maillard reaction significantly influences bread crust development, producing complex flavors and a rich brown color through the interaction of amino acids and reducing sugars at high temperatures. This chemical process enhances the aroma by generating volatile compounds that contribute to the characteristic toasty and nutty scent of baked bread.

Toasting further intensifies these Maillard reaction effects by raising the surface temperature of the bread, accelerating browning and flavor formation. The resulting crust texture becomes crispier, while the aroma profile deepens, distinguishing toasted bread from simply baked varieties.

Health Implications: Toasting Compared to Maillardization

Toasting bread primarily triggers caramelization, which enhances flavor with fewer harmful compounds compared to Maillardization, a reaction that produces advanced glycation end products (AGEs) linked to inflammation. Maillardization occurs during baking and produces acrylamide, a potential carcinogen, especially when bread is overcooked or burnt. Choosing light toasting minimizes acrylamide formation while preserving nutrients and reducing health risks associated with Maillard reaction byproducts.

Best Breads for Toasting Versus Maillardization

Toasting and Maillardization both enhance bread flavors but affect texture and aroma differently. Toasting primarily dries and crisps bread, while Maillardization involves a chemical reaction creating complex flavors and browning.

- Sourdough - Ideal for toasting due to its chewy crumb and tangy flavor that crisps well without becoming too hard.

- White bread - Best for Maillardization because its higher sugar content promotes browning and rich flavor development.

- Whole grain bread - Great for both processes, offering a hearty texture that complements toasting and Maillard browning flavors.

Choosing the right bread enhances the toasting or Maillardization experience by balancing texture and flavor complexity.

Practical Tips for Achieving Perfect Toast and Maillardized Bread

Toasting bread involves applying direct heat to the surface, which quickly drives off moisture and develops a crisp texture, while Maillardization is a chemical reaction between amino acids and reducing sugars that creates complex flavors and browning. Achieving perfect toast requires consistent heat at medium-high temperature, ensuring even browning without burning the bread.

For Maillardized bread, maintaining a balanced temperature between 140degC and 165degC (284degF to 329degF) promotes optimal flavor development and golden crust formation. Using slightly drier bread and allowing proper resting time after toasting enhances the deep, savory notes unique to Maillard reactions.

Related Important Terms

Differential Browning Spectrum

Toasting primarily induces surface caramelization resulting in a distinct golden-brown crust, while Maillardization generates a complex spectrum of browning through amino acids and reducing sugars interaction, producing richer flavors and deeper coloration. The differential browning spectrum in toasting emphasizes thermal caramelization, whereas Maillardization showcases a multifaceted chemical reaction yielding diverse taste and aroma compounds.

Maillard Zone Threshold

The Maillard Zone Threshold defines the temperature range, typically between 140degC to 165degC, where Maillardization occurs, causing bread to develop complex flavors and browning beyond simple toasting. Toasting primarily involves dry heat application to reduce moisture, but only surpassing the Maillard Zone Threshold initiates the chemical reactions that create the rich, caramelized crust characteristic of perfectly toasted bread.

Enzymatic Pre-Tan

Toasting bread primarily relies on Maillardization, a non-enzymatic browning reaction between amino acids and reducing sugars, which develops flavor and color at high temperatures above 140degC. Before this, enzymatic pre-tan processes in raw dough involve enzymatic browning facilitated by polyphenol oxidase, affecting phenolic compounds and contributing subtle flavor precursors that are transformed during Maillard reactions upon toasting.

Flavor-layering Toast Stack

Toasting bread triggers Maillardization, creating complex flavor compounds through amino acid and sugar reactions, enhancing the bread's aroma and texture. Layering multiple toasted slices in a toast stack intensifies these flavor profiles by combining varied Maillardized surfaces, resulting in a richer, more nuanced taste experience.

Crust-O-Maillard Mapping

Crust-O-Maillard Mapping highlights the distinct chemical pathways involved in toasting and Maillardization of bread, where toasting primarily induces caramelization of surface sugars, while Maillardization involves a complex reaction between amino acids and reducing sugars forming the characteristic browned crust. This mapping allows precise control over flavor and texture development during baking, optimizing crust color and aroma by balancing temperature and time to favor Maillard reactions over simple caramelization.

Pyrolytic Toastpoint

Pyrolytic toastpoint refers to the temperature at which bread undergoes pyrolysis, causing the breakdown of organic compounds and resulting in a distinct toasted flavor and darker crust, differing from the Maillard reaction that primarily involves amino acids and reducing sugars forming complex flavor compounds and browning. While Maillardization contributes to the appealing aroma and taste during toasting, pyrolytic changes dominate at higher temperatures, producing deeper caramelization and smoky notes unique to the toastpoint threshold.

Umami Crumb Shift

Toasting bread induces Maillardization, a complex chemical reaction between amino acids and reducing sugars that enhances umami flavor by creating the Umami Crumb Shift, where the crumb's texture transforms to a savory, slightly caramelized profile. This shift increases the bread's depth of flavor compared to simple drying, emphasizing rich, savory notes characteristic of toasted crust.

Non-Maillard Toasting

Non-Maillard toasting of bread primarily involves caramelization, where sugars break down at higher temperatures without the involvement of amino acids, resulting in a distinct flavor profile and browning different from Maillardization. This process occurs above 160degC and emphasizes sugar chemistry rather than protein-sugar interaction, producing a crisp texture without the complex savory notes characteristic of Maillard reactions.

Aromatic Browning Divergence

Toasting triggers aromatic browning primarily through Maillard reactions and caramelization, producing a complex profile of flavor compounds distinct from the simpler Maillardization that occurs during baking. The divergence in aromatic profiles arises because toasting involves higher surface temperatures and direct heat exposure, intensifying caramelization and creating a richer, more pronounced aroma compared to the subtler Maillardization within the bread's crumb.

Toasting vs Maillardization for bread. Infographic

cookingdiff.com

cookingdiff.com