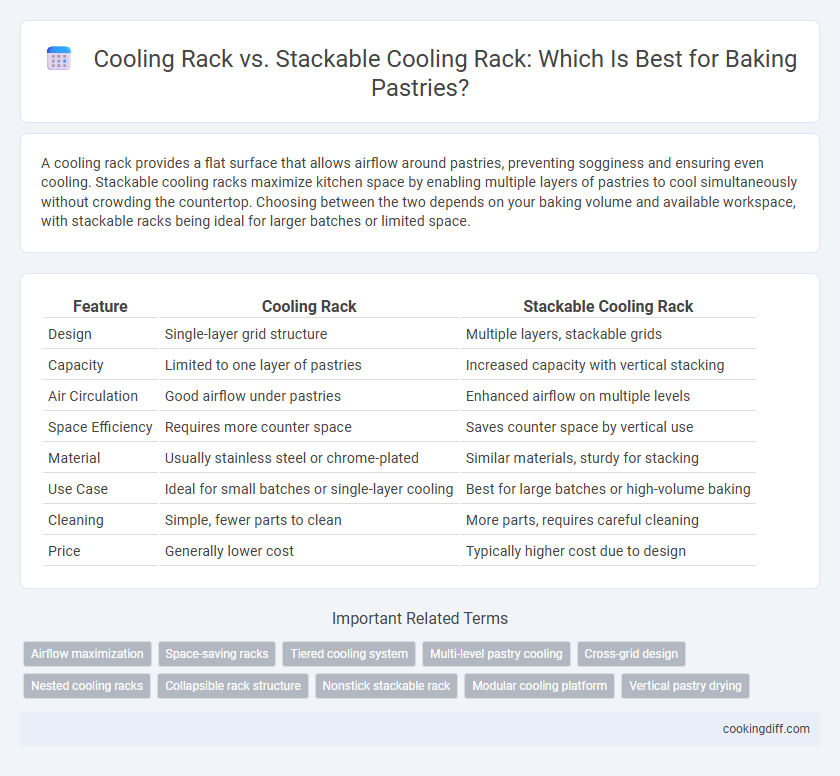

A cooling rack provides a flat surface that allows airflow around pastries, preventing sogginess and ensuring even cooling. Stackable cooling racks maximize kitchen space by enabling multiple layers of pastries to cool simultaneously without crowding the countertop. Choosing between the two depends on your baking volume and available workspace, with stackable racks being ideal for larger batches or limited space.

Table of Comparison

| Feature | Cooling Rack | Stackable Cooling Rack |

|---|---|---|

| Design | Single-layer grid structure | Multiple layers, stackable grids |

| Capacity | Limited to one layer of pastries | Increased capacity with vertical stacking |

| Air Circulation | Good airflow under pastries | Enhanced airflow on multiple levels |

| Space Efficiency | Requires more counter space | Saves counter space by vertical use |

| Material | Usually stainless steel or chrome-plated | Similar materials, sturdy for stacking |

| Use Case | Ideal for small batches or single-layer cooling | Best for large batches or high-volume baking |

| Cleaning | Simple, fewer parts to clean | More parts, requires careful cleaning |

| Price | Generally lower cost | Typically higher cost due to design |

Overview: Cooling Rack vs Stackable Cooling Rack

What are the key differences between a cooling rack and a stackable cooling rack for pastries? A cooling rack provides a single layer for air circulation to cool baked goods evenly, ideal for small batches. Stackable cooling racks maximize vertical space and allow multiple layers of pastries to cool simultaneously, enhancing kitchen efficiency during large baking sessions.

Space Efficiency: Standard vs Stackable Racks

Stackable cooling racks maximize kitchen space by allowing multiple pastry layers to cool vertically, reducing countertop clutter. Standard cooling racks offer single-layer cooling but require more horizontal space, which can limit efficiency in smaller kitchens.

- Stackable racks save space - They allow several trays of pastries to cool simultaneously without spreading out.

- Standard racks require more surface area - Cooling multiple batches requires clearing more counter space.

- Stackable racks enhance airflow - Their design facilitates better cooling in compact areas.

Material Durability and Construction

| Cooling Rack | Typically made from stainless steel or chrome-plated steel, offering excellent rust resistance and sturdy construction. Welded or spot-welded joints enhance durability, supporting even heat distribution to prevent soggy pastries. |

| Stackable Cooling Rack | Constructed from reinforced stainless steel with interlocking design for vertical stacking, maximizing space without compromising strength. Durable welds and heavy-gauge wire frames ensure stability under the weight of multiple layers of pastries. |

Airflow and Cooling Performance

Cooling racks enhance airflow around pastries, promoting even cooling and preventing sogginess. Stackable cooling racks optimize space without significantly compromising airflow due to their spaced design.

- Airflow Efficiency - Single cooling racks provide unobstructed air circulation on all sides of the pastries.

- Space Utilization - Stackable racks allow multiple layers of pastries to cool simultaneously, saving countertop space.

- Cooling Performance - Both rack types prevent steam buildup beneath pastries, preserving texture and freshness effectively.

Cleaning and Maintenance Comparison

Cooling racks typically feature a simple wire grid design that allows for easy access to all surfaces, making cleaning straightforward with minimal effort. Stackable cooling racks, while space-saving, have more complex structures with additional layers that can trap crumbs and grease, requiring more thorough scrubbing or dismantling during maintenance.

Stainless steel cooling racks often resist rust and stains, simplifying upkeep, whereas some budget stackable racks use coated metal that may chip or wear over time, complicating cleaning. Both types benefit from dishwasher-safe designs, but the smaller, individual grids of a single cooling rack facilitate faster drying and less residue buildup compared to stacked versions.

Storage Convenience and Solutions

Stackable cooling racks offer enhanced storage convenience by maximizing vertical space, ideal for small kitchens or bakeries with limited counter area. Unlike traditional single-layer cooling racks, stackable models allow multiple trays of pastries to cool simultaneously without cluttering surfaces. Their compact design provides efficient solutions for organizing and storing baked goods, reducing countertop mess and improving workflow efficiency.

Versatility for Different Pastry Types

A stackable cooling rack offers enhanced versatility for different pastry types by maximizing vertical space and allowing multiple layers of delicate items to cool simultaneously without overcrowding. Traditional cooling racks provide a single layer, suitable for larger pastries but less efficient when baking multiple small batches like cookies or eclairs. Choosing a stackable design can optimize air circulation and cooling time, crucial for maintaining pastry texture and preventing sogginess.

Stability and Safety Considerations

Cooling racks provide stable surfaces with wide, sturdy legs that prevent wobbling, ensuring pastries cool evenly and safely. Stackable cooling racks, while space-efficient, may compromise stability if overloaded or improperly stacked, increasing the risk of tipping.

For safety, single-layer cooling racks reduce the chance of accidents, especially when handling hot or delicate pastries. Stackable racks require careful weight distribution and secure stacking to maintain safety during the cooling process.

Price and Value Analysis

Cooling racks typically offer a lower price point compared to stackable cooling racks, making them a budget-friendly option for home bakers focused on basic pastry cooling needs. Standard cooling racks provide sufficient airflow but lack the vertical storage efficiency of stackable models.

Stackable cooling racks, though higher in cost, deliver enhanced value by maximizing counter space and allowing multiple trays of pastries to cool simultaneously, ideal for large batches or professional settings. Their durable construction and space-saving design contribute to long-term savings by reducing the need for additional racks. Investing in stackable cooling racks can improve kitchen workflow and justify the initial price premium for serious bakers.

Related Important Terms

Airflow maximization

Stackable cooling racks enhance airflow around pastries by allowing multiple layers of baked goods to cool simultaneously without restricting ventilation, unlike traditional single-tier racks that limit exposure to air only on the top and sides. This design significantly reduces cooling time and helps maintain pastry texture by preventing condensation and sogginess.

Space-saving racks

Stackable cooling racks maximize kitchen space by allowing multiple layers of pastries to cool simultaneously while maintaining proper air circulation for even cooling. Traditional single-tier cooling racks occupy more counter area and limit the number of baked goods that can be cooled at once, making stackable racks ideal for space-efficient baking environments.

Tiered cooling system

A tiered cooling system with stackable cooling racks maximizes kitchen space by allowing multiple layers of pastries to cool simultaneously, improving air circulation and reducing cooling time. Traditional single-layer cooling racks offer limited surface area, making stackable racks more efficient for handling large batches of baked goods.

Multi-level pastry cooling

Stackable cooling racks maximize space by allowing multi-level pastry cooling, promoting faster airflow around baked goods and preventing sogginess. Traditional single-layer cooling racks provide ample surface area but lack the vertical efficiency of stackable designs, which are ideal for handling large batches in limited kitchen space.

Cross-grid design

The cross-grid design in stackable cooling racks enhances airflow around pastries, promoting even cooling and preventing sogginess compared to traditional single-layer cooling racks. This structure allows multiple trays to be cooled simultaneously without compromising space or air circulation.

Nested cooling racks

Nested cooling racks maximize kitchen space by allowing multiple layers of pastries to cool simultaneously without crowding, improving air circulation and reducing cooling time. Unlike standard racks, stackable options enhance efficiency in busy bakeries by enabling organized storage and quick access to baked goods.

Collapsible rack structure

Collapsible stackable cooling racks optimize kitchen space by allowing multiple layers of pastries to cool simultaneously without overcrowding, enhancing airflow for faster, even cooling. Their foldable design simplifies storage compared to traditional cooling racks, making them ideal for both professional bakers and home enthusiasts seeking efficient countertop management.

Nonstick stackable rack

Nonstick stackable cooling racks maximize airflow around pastries, preventing sogginess and speeding up the cooling process compared to standard single-layer cooling racks. Their space-saving, tiered design is ideal for bakeries or home kitchens needing efficient cooling without compromising pastry texture or quality.

Modular cooling platform

A stackable cooling rack offers a modular cooling platform design, maximizing kitchen space by allowing multiple layers of pastries to cool simultaneously while maintaining optimal air circulation. Traditional single-tier cooling racks provide ample airflow but lack the vertical scalability needed for high-volume baking tasks.

Cooling rack vs stackable cooling rack for pastries Infographic

cookingdiff.com

cookingdiff.com