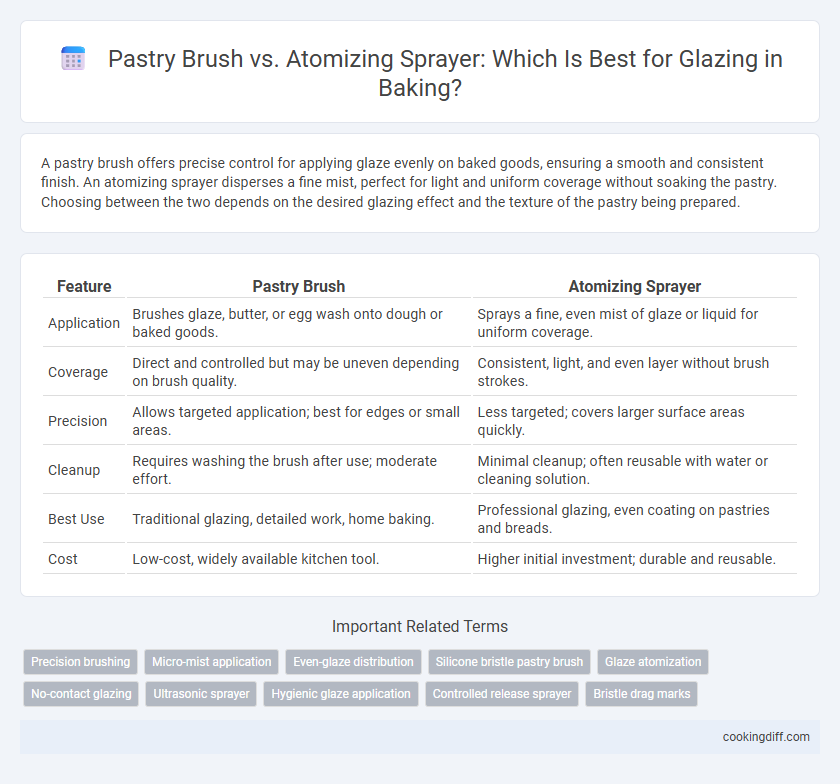

A pastry brush offers precise control for applying glaze evenly on baked goods, ensuring a smooth and consistent finish. An atomizing sprayer disperses a fine mist, perfect for light and uniform coverage without soaking the pastry. Choosing between the two depends on the desired glazing effect and the texture of the pastry being prepared.

Table of Comparison

| Feature | Pastry Brush | Atomizing Sprayer |

|---|---|---|

| Application | Brushes glaze, butter, or egg wash onto dough or baked goods. | Sprays a fine, even mist of glaze or liquid for uniform coverage. |

| Coverage | Direct and controlled but may be uneven depending on brush quality. | Consistent, light, and even layer without brush strokes. |

| Precision | Allows targeted application; best for edges or small areas. | Less targeted; covers larger surface areas quickly. |

| Cleanup | Requires washing the brush after use; moderate effort. | Minimal cleanup; often reusable with water or cleaning solution. |

| Best Use | Traditional glazing, detailed work, home baking. | Professional glazing, even coating on pastries and breads. |

| Cost | Low-cost, widely available kitchen tool. | Higher initial investment; durable and reusable. |

Overview: Pastry Brush vs Atomizing Sprayer for Glazing

Which tool provides a smoother, more even glaze: a pastry brush or an atomizing sprayer? Pastry brushes offer precise control and are ideal for thicker glazes, allowing for targeted application. Atomizing sprayers create a fine mist that ensures an even, delicate coating, perfect for lighter glazes or achieving a glossy finish without brush marks.

Key Differences in Application Techniques

Pastry brushes apply glaze by direct contact, allowing for controlled and even spreading over surfaces, ideal for thick or sticky coatings. Atomizing sprayers disperse a fine mist of glaze, creating a light, uniform layer without disturbing delicate textures.

- Contact Precision - Pastry brushes provide tactile control, perfect for detailed glazing on pastries and bread.

- Coverage Uniformity - Atomizing sprayers distribute glaze evenly over larger areas with minimal effort.

- Impact on Texture - Brushes may alter surface texture due to bristle contact, whereas sprayers preserve the original finish.

Precision and Control During Glazing

Pastry brushes offer precise control when glazing, allowing for targeted application on specific areas of pastries and ensuring an even coat. The bristles conform to the surface, making it easier to manage thickness and avoid over-glazing.

Atomizing sprayers distribute glaze in a fine mist, providing a uniform layer over larger surfaces but less accuracy for intricate designs. This tool excels for quick coverage, though it may lack the precision needed for detailed pastry decoration.

Impact on Glazing Evenness and Coverage

Pastry brushes provide controlled application of glaze, allowing for precise coverage but can sometimes result in uneven layers due to bristle marks or inconsistent pressure. Atomizing sprayers create a fine mist that ensures uniform glazing, minimizing streaks and promoting even coverage over delicate baked goods.

The use of atomizing sprayers enhances glazing evenness by distributing liquid glaze in a consistent layer, especially useful for smooth finishes on pastries and cakes. Pastry brushes, while offering tactile control, require skill to avoid pooling or patchy application, which can affect the visual appeal and texture. Choosing between these tools depends on the desired finish and the type of pastry being glazed, with atomizers excelling in even, light coverage and brushes suited for thicker, targeted application.

Material Compatibility: Types of Glazes

| Tool | Material Compatibility | Types of Glazes |

|---|---|---|

| Pastry Brush | Bristles made of natural fibers, silicone, or nylon provide varying absorbency and heat resistance. Ideal for thick or viscous glazes like butter, egg wash, and syrup-based coatings. | Works best with heavy, textured glazes including egg wash, melted butter, honey, and sugar syrups that require precise, controlled application. |

| Atomizing Sprayer | Typically made of glass or plastic, compatible with liquid glazes of low viscosity to prevent clogging. Suitable for water-based or alcohol-based glazes that need an even, fine mist. | Optimized for light, thin glazes such as simple syrup, flavored extracts, or water-glazed finishes that benefit from an even, delicate coating without excess liquid pooling. |

Speed and Efficiency in the Baking Process

Pastry brushes offer precise control for glazing small or detailed areas but can be slower due to manual application. Atomizing sprayers deliver an even, fine mist quickly, covering large surfaces efficiently and reducing baking preparation time. Choosing an atomizing sprayer enhances speed and consistency in glazing, especially for professional or high-volume baking environments.

Hygiene and Cleaning Considerations

Pastry brushes require thorough cleaning after each use to prevent the buildup of food particles and bacteria, which can compromise hygiene during glazing. Atomizing sprayers offer a more hygienic alternative by minimizing direct contact with the glaze and reducing cross-contamination risks. Regular disassembly and cleaning of sprayer components are essential to maintain optimal sanitation standards in baking environments.

Suitability for Home Bakers vs Professionals

Pastry brushes provide precise control and allow home bakers to apply glazes evenly with minimal waste, making them ideal for small-scale baking projects. Their affordability and ease of use suit beginners and casual bakers who prioritize simplicity and effectiveness.

Atomizing sprayers distribute fine, uniform mists of glaze, offering professionals a faster, more consistent finish suitable for high-volume baking environments. These sprayers enhance efficiency and glazing quality in commercial kitchens but require investment and maintenance that may be excessive for home use.

Cost Comparison and Long-term Value

Pastry brushes typically have a lower initial cost compared to atomizing sprayers, making them more accessible for home bakers. Over time, atomizing sprayers provide more uniform glazing and use less product, potentially offering better long-term value despite their higher upfront price.

- Lower Initial Cost - Pastry brushes are inexpensive and widely available for immediate use.

- Durability and Maintenance - Atomizing sprayers require occasional cleaning but can last longer if properly maintained.

- Efficiency in Usage - Atomizing sprayers apply a fine mist, reducing glaze waste compared to brushes.

Choosing between a pastry brush and an atomizing sprayer depends on balancing upfront cost against consistent performance and product savings over time.

Related Important Terms

Precision brushing

Pastry brushes offer superior control for precision glazing, allowing bakers to evenly apply thin layers of egg wash or butter to pastries without oversaturating. Atomizing sprayers distribute glaze more diffusely, making them less ideal for detailed brushing where exact coverage and thickness are crucial for achieving a perfectly golden, crisp finish.

Micro-mist application

The pastry brush provides direct, controlled application of glazes but can result in uneven layering and absorbed moisture, whereas the atomizing sprayer delivers a fine micro-mist that ensures an even, delicate coating ideal for achieving smooth, glossy finishes. Micro-mist application from an atomizing sprayer enhances glaze distribution, minimizes waste, and reduces the risk of altering dough texture during glazing.

Even-glaze distribution

A pastry brush allows precise control for even glaze application, ensuring thorough coverage without pooling or streaking on the pastry surface. An atomizing sprayer disperses a fine mist, creating a smooth, uniform glaze layer that reduces the risk of oversaturation and achieves consistent sheen across delicate baked goods.

Silicone bristle pastry brush

A silicone bristle pastry brush offers precise control and even application of glazes, ensuring a smooth, consistent finish without shedding bristles into the baked goods. Unlike atomizing sprayers that deliver a fine mist, silicone brushes enable targeted, thicker glaze coverage, essential for achieving a glossy, appetizing appearance on pastries.

Glaze atomization

Glaze atomization with an atomizing sprayer ensures an even, fine mist that uniformly coats pastries without saturating the dough, enhancing texture and appearance. In contrast, a pastry brush delivers a heavier, less consistent layer, which can lead to uneven glazing and potential sogginess.

No-contact glazing

Pastry brushes apply glaze directly, potentially disturbing delicate pastries, while atomizing sprayers enable even, no-contact glazing that preserves texture and detail. Using an atomizing sprayer reduces contamination risk and ensures a smooth, consistent finish on cakes, tarts, and croissants.

Ultrasonic sprayer

Ultrasonic sprayers offer precise, even glazing by producing a fine mist that enhances the sheen and texture of baked goods without oversaturating the surface. Compared to pastry brushes, these atomizing sprayers reduce glaze waste and ensure uniform coverage, improving both appearance and flavor retention in delicate pastries.

Hygienic glaze application

Pastry brushes offer direct control for glaze application but can harbor bacteria if not properly cleaned, posing hygienic risks. Atomizing sprayers provide a more sanitary, even misting of glaze, minimizing contact and contamination while ensuring consistent coverage.

Controlled release sprayer

A pastry brush allows precise application of glaze but may cause uneven distribution and soaking, while a controlled release atomizing sprayer delivers a fine mist for an even, light coating, enhancing texture and appearance without soaking the pastry. The atomizing sprayer's adjustable nozzle provides consistent coverage and reduces waste, making it ideal for delicate glazing tasks.

Pastry brush vs atomizing sprayer for glazing Infographic

cookingdiff.com

cookingdiff.com