Blanching involves briefly exposing produce to hot water or steam to loosen skins, making peeling easier and reducing enzyme activity, while High-Pressure Processing (HPP) uses intense pressure to achieve similar effects without heat, preserving texture and nutrients. Blanching can cause slight nutrient loss and texture softening, whereas HPP maintains freshness and extends shelf life by inactivating microbes without thermal degradation. For peeling preparation, HPP is preferred when preserving sensory qualities and nutritional value is critical, but blanching remains a cost-effective and widely used method.

Table of Comparison

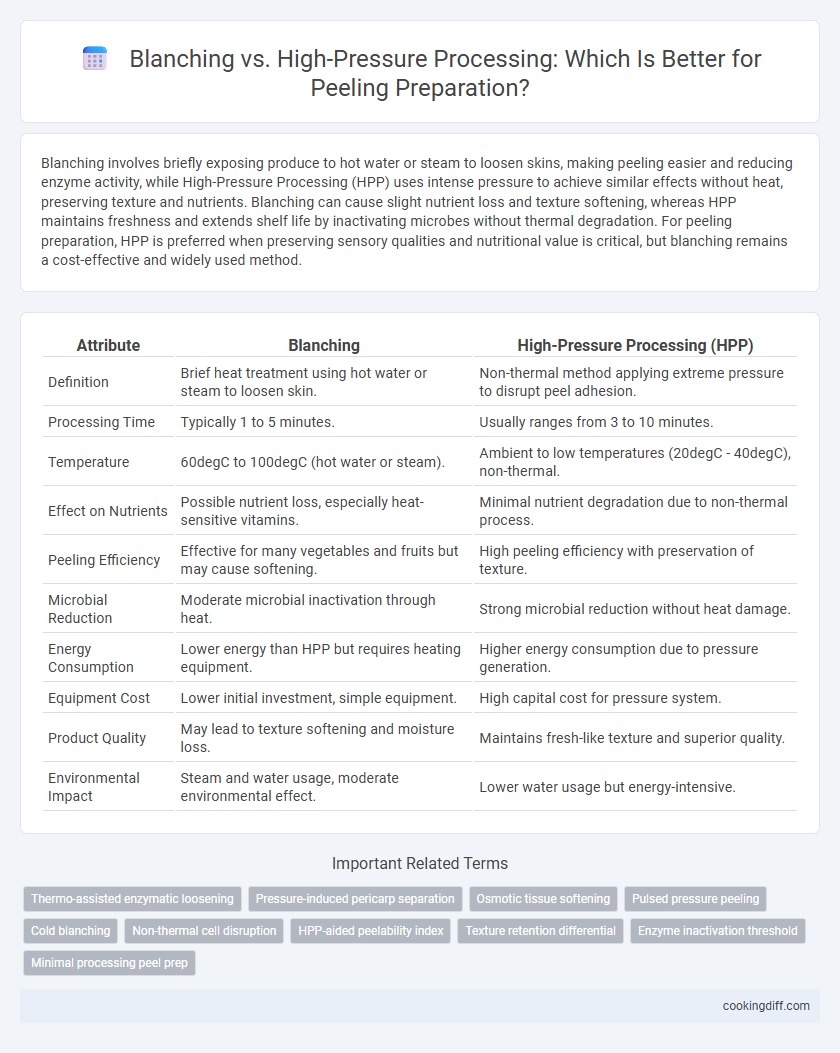

| Attribute | Blanching | High-Pressure Processing (HPP) |

|---|---|---|

| Definition | Brief heat treatment using hot water or steam to loosen skin. | Non-thermal method applying extreme pressure to disrupt peel adhesion. |

| Processing Time | Typically 1 to 5 minutes. | Usually ranges from 3 to 10 minutes. |

| Temperature | 60degC to 100degC (hot water or steam). | Ambient to low temperatures (20degC - 40degC), non-thermal. |

| Effect on Nutrients | Possible nutrient loss, especially heat-sensitive vitamins. | Minimal nutrient degradation due to non-thermal process. |

| Peeling Efficiency | Effective for many vegetables and fruits but may cause softening. | High peeling efficiency with preservation of texture. |

| Microbial Reduction | Moderate microbial inactivation through heat. | Strong microbial reduction without heat damage. |

| Energy Consumption | Lower energy than HPP but requires heating equipment. | Higher energy consumption due to pressure generation. |

| Equipment Cost | Lower initial investment, simple equipment. | High capital cost for pressure system. |

| Product Quality | May lead to texture softening and moisture loss. | Maintains fresh-like texture and superior quality. |

| Environmental Impact | Steam and water usage, moderate environmental effect. | Lower water usage but energy-intensive. |

Introduction to Blanching and High-Pressure Processing

| Blanching involves brief exposure to boiling water or steam to inactivate enzymes and loosen fruit or vegetable skins, facilitating efficient peeling. High-Pressure Processing (HPP) uses extreme pressure up to 600 MPa to disrupt cell structures without heat, preserving texture and nutrients during peeling preparation. Selecting between blanching and HPP depends on desired product quality, processing time, and equipment availability. |

Overview of Peeling Preparation in Food Processing

Peeling preparation in food processing involves methods that facilitate the removal of skins from fruits and vegetables, improving texture and quality. Blanching and High-Pressure Processing (HPP) are two key techniques with distinct impacts on peeling efficiency and product safety.

- Blanching - Uses heat treatment to soften skins and inactivate enzymes, making peeling easier and enhancing shelf life.

- High-Pressure Processing (HPP) - Applies intense pressure to disrupt tissue structure without heat, preserving nutrients while aiding in peeling.

- Comparison - Blanching is faster but may degrade heat-sensitive nutrients, whereas HPP preserves freshness but requires specialized equipment.

Choosing between blanching and HPP depends on desired product characteristics, cost considerations, and processing goals.

How Blanching Works in Peeling Applications

Blanching softens the surface of fruits and vegetables by briefly exposing them to hot water or steam, which helps loosen the skin for easier peeling. This thermal treatment inactivates enzymes and reduces microbial load, improving peeling efficiency and product quality. Blanching is widely used due to its simplicity, cost-effectiveness, and ability to preserve texture before high-pressure processing or other peeling methods.

High-Pressure Processing: Principles and Mechanisms

High-Pressure Processing (HPP) applies uniform pressure up to 600 MPa to disrupt cellular structures, facilitating easier peeling of fruits and vegetables. Unlike blanching, HPP preserves nutritional content and sensory qualities by operating at low temperatures, minimizing thermal degradation. The pressure-induced permeabilization of cell walls in HPP enhances peeling efficiency while maintaining product freshness and extending shelf life.

Effectiveness of Blanching for Peeling Different Foods

Blanching effectively loosens the skin of various fruits and vegetables, such as tomatoes and peaches, by softening the outer layers through brief exposure to boiling water or steam. This process facilitates peeling by weakening the cellular structure, making it easier to remove skins without damaging the flesh.

In comparison to high-pressure processing, blanching is generally faster and more cost-effective for peeling preparation, particularly for soft-skinned produce. However, it may cause minor nutrient loss and texture changes, which high-pressure processing can better preserve while still aiding in skin removal.

Efficiency of High-Pressure Processing in Peel Removal

High-Pressure Processing (HPP) significantly increases efficiency in peel removal compared to traditional blanching by disrupting cellular structures without heat damage. HPP enhances texture retention and reduces processing time, leading to higher quality peel-prepped produce.

- Non-Thermal Peel Disruption - HPP uses pressure to weaken cell adhesion and facilitate easy peel removal without compromising internal fruit or vegetable quality.

- Reduced Processing Time - Unlike blanching's prolonged heat exposure, HPP achieves peel loosening rapidly, improving throughput in industrial applications.

- Quality Retention - High-pressure treatment preserves color, flavor, and nutrients, avoiding the texture degradation often caused by blanching.

Nutritional Impact: Blanching vs High-Pressure Processing

Blanching involves brief exposure to boiling water or steam, which can cause some loss of water-soluble vitamins like vitamin C and B-complex vitamins during the peeling preparation process. High-Pressure Processing (HPP) preserves more nutritional content by applying intense pressure without heat, maintaining higher levels of vitamins and antioxidants in peeled produce.

Studies show that HPP-treated fruits and vegetables retain significantly greater amounts of phenolic compounds and enzymes compared to blanched counterparts, benefiting overall nutritional quality. This preservation makes HPP a superior method for maintaining nutrient density during peeling preparation in food processing.

Quality and Texture Comparison After Peeling

Blanching effectively softens fruit skins, facilitating easier peeling while maintaining firmness, but may cause slight nutrient loss due to heat exposure. High-pressure processing (HPP) preserves texture more intact and enhances product freshness without thermal degradation, offering superior quality retention.

- Texture Retention - HPP maintains a firmer texture post-peeling compared to blanching, which can soften tissues excessively.

- Color and Appearance - Blanching can cause mild browning, whereas HPP preserves natural color better due to non-thermal treatment.

- Nutrient Preservation - HPP retains higher levels of vitamins and antioxidants compared to blanching's heat-induced losses.

Environmental and Energy Considerations

How do blanching and high-pressure processing compare in terms of environmental and energy impacts for peeling preparation? Blanching consumes substantial water and energy due to heating requirements, leading to higher carbon emissions compared to high-pressure processing, which operates at lower temperatures without water usage. High-pressure processing offers a more sustainable alternative by reducing water consumption and energy demands while maintaining peeling efficiency.

Related Important Terms

Thermo-assisted enzymatic loosening

Thermo-assisted enzymatic loosening in blanching uses controlled heat to activate cell wall-degrading enzymes, facilitating easier peeling by softening the fruit or vegetable surface. In contrast, High-Pressure Processing (HPP) disrupts cellular structures through intense pressure without heat, preserving fresh sensory qualities but showing less efficiency in enzyme activation for peeling preparation.

Pressure-induced pericarp separation

Pressure-induced pericarp separation in high-pressure processing enables efficient peeling preparation by disrupting cell adhesion without the thermal degradation associated with blanching. This method preserves texture and nutritional quality while facilitating easier removal of the pericarp compared to traditional blanching techniques.

Osmotic tissue softening

Blanching uses heat to induce osmotic tissue softening, facilitating easier peeling by disrupting cell membranes and promoting moisture loss. In contrast, High-Pressure Processing (HPP) applies intense pressure, causing cellular deformation and enhanced enzyme inactivation without significant osmotic effects, resulting in a different texture modification during peeling preparation.

Pulsed pressure peeling

Pulsed pressure peeling, a method within high-pressure processing, enhances peeling efficiency by applying cyclical pressure variations that disrupt cellular adhesion in fruits and vegetables, outperforming traditional blanching which relies on heat to weaken skin attachment. This technique preserves nutritional quality and texture by minimizing thermal damage while facilitating easier skin removal during peeling preparation.

Cold blanching

Cold blanching offers a gentle method for peeling preparation by maintaining low temperatures that preserve texture and nutrient content, unlike high-pressure processing which can alter cell structure through intense pressure. This process reduces enzymatic activity while minimizing thermal damage, making it ideal for delicate fruits and vegetables requiring precise peeling.

Non-thermal cell disruption

Blanching uses high-temperature steam or boiling water to denature enzymes and soften fruit skins, often causing thermal damage and nutrient loss; in contrast, High-Pressure Processing (HPP) applies ultra-high hydrostatic pressure to disrupt cell structures non-thermally, preserving texture and enhancing peeling efficiency without compromising nutritional quality. HPP-induced cell wall weakening facilitates easier peeling with minimal thermal effects, making it a superior non-thermal alternative for preparing fruits and vegetables prior to peeling operations.

HPP-aided peelability index

High-Pressure Processing (HPP) significantly enhances the peelability index compared to traditional blanching by disrupting cellular structures without heat damage, facilitating easier peel removal. This improvement in peelability under HPP treatment results in higher product yield and preserves sensory qualities better than blanching methods.

Texture retention differential

Blanching softens food by denaturing enzymes and partially cooking, often leading to texture loss during peeling preparation, whereas high-pressure processing (HPP) preserves cellular integrity, resulting in superior texture retention. HPP maintains firmness and crispness in fruits and vegetables better than blanching, making it a preferred method for delicate produce requiring texture-sensitive peeling prep.

Enzyme inactivation threshold

Blanching typically inactivates enzymes at temperatures around 85-95degC for 1-3 minutes, ensuring the breakdown of enzymatic activity necessary for peeling preparation. High-Pressure Processing (HPP) achieves enzyme inactivation at lower temperatures, applying pressures of 400-600 MPa to disrupt enzyme structure without thermal damage, offering an alternative to heat-based blanching.

Blanching vs High-Pressure Processing for peeling prep. Infographic

cookingdiff.com

cookingdiff.com