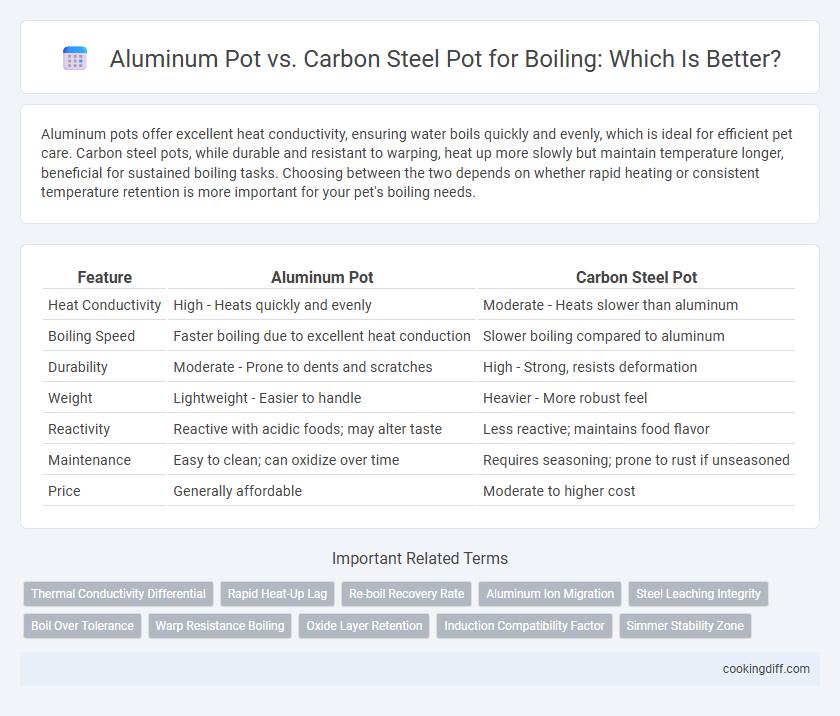

Aluminum pots offer excellent heat conductivity, ensuring water boils quickly and evenly, which is ideal for efficient pet care. Carbon steel pots, while durable and resistant to warping, heat up more slowly but maintain temperature longer, beneficial for sustained boiling tasks. Choosing between the two depends on whether rapid heating or consistent temperature retention is more important for your pet's boiling needs.

Table of Comparison

| Feature | Aluminum Pot | Carbon Steel Pot |

|---|---|---|

| Heat Conductivity | High - Heats quickly and evenly | Moderate - Heats slower than aluminum |

| Boiling Speed | Faster boiling due to excellent heat conduction | Slower boiling compared to aluminum |

| Durability | Moderate - Prone to dents and scratches | High - Strong, resists deformation |

| Weight | Lightweight - Easier to handle | Heavier - More robust feel |

| Reactivity | Reactive with acidic foods; may alter taste | Less reactive; maintains food flavor |

| Maintenance | Easy to clean; can oxidize over time | Requires seasoning; prone to rust if unseasoned |

| Price | Generally affordable | Moderate to higher cost |

Introduction to Boiling: Aluminum vs Carbon Steel Pots

Which pot material performs better for boiling, aluminum or carbon steel? Aluminum pots offer excellent heat conductivity, ensuring water reaches boiling point quickly and evenly. Carbon steel pots, while slower to heat, provide superior durability and retain heat longer, making them ideal for sustained boiling tasks.

Material Composition: Aluminum and Carbon Steel Explained

Aluminum pots are made from a lightweight metal known for excellent thermal conductivity, allowing water to reach boiling point quickly and evenly. The metal's natural oxide layer provides moderate corrosion resistance but can react with acidic foods.

Carbon steel pots consist primarily of iron with a small carbon content, offering high durability and heat retention suitable for sustained boiling. They develop a protective patina through seasoning, enhancing rust resistance and non-stick properties over time.

Thermal Conductivity: Boiling Efficiency Compared

Aluminum pots offer superior thermal conductivity, approximately 205 W/m*K, enabling faster and more even boiling compared to carbon steel pots, which have a thermal conductivity around 50 W/m*K. This high thermal conductivity of aluminum reduces boiling time and improves energy efficiency.

Carbon steel pots, while less thermally conductive, retain heat longer once heated, which can provide more consistent boiling temperatures over time. Aluminum pots, due to rapid heat transfer, are ideal for quick boiling but may require more precise heat control to avoid hotspots. Choosing between aluminum and carbon steel pots depends on balancing the need for quick boiling and heat retention during cooking.

Heat Distribution and Retention Analysis

Aluminum pots offer superior heat distribution due to their high thermal conductivity, enabling even boiling and reducing hotspots that can cause food to burn. However, aluminum retains heat less effectively, causing the temperature to drop quickly once removed from the heat source.

Carbon steel pots exhibit moderate heat distribution but excel in heat retention, maintaining a consistent, stable boiling temperature for longer periods. Their thickness and density allow them to hold heat efficiently, making them ideal for prolonged boiling tasks where temperature consistency is crucial.

Durability and Longevity in Boiling Applications

Carbon steel pots exhibit superior durability and maintain structural integrity better under prolonged boiling compared to aluminum pots. Aluminum pots are prone to warping and corrosion when frequently exposed to high heat and water.

- Carbon Steel Strength - Carbon steel withstands repeated boiling cycles without significant degradation.

- Aluminum Vulnerability - Aluminum is softer and more reactive, leading to faster surface wear and potential pitting.

- Longevity in Use - Carbon steel's robust composition enhances its lifespan in boiling applications.

For extended boiling tasks, carbon steel pots offer greater durability and longevity than aluminum ones.

Reaction with Food During Boiling

| Material | Reaction with Food During Boiling |

|---|---|

| Aluminum Pot | Aluminum reacts with acidic foods, potentially imparting a metallic taste and causing slight discoloration; anodized versions reduce this effect by creating a non-reactive surface. |

| Carbon Steel Pot | Carbon steel may react with acidic ingredients, causing minor flavor alterations and possible rust if not properly seasoned or maintained, but it generally remains stable during boiling with neutral foods. |

Weight and Handling Comfort in Everyday Use

Aluminum pots are significantly lighter than carbon steel, making them easier to maneuver during everyday boiling tasks. The lighter weight reduces strain on wrists and enhances handling comfort, especially when filled with water.

- Weight Advantage - Aluminum pots typically weigh 30-50% less than carbon steel ones of the same size.

- Handling Comfort - The reduced weight of aluminum ensures effortless lifting and pouring during cooking.

- Ease of Use - Aluminum handles remain cooler and are often ergonomically designed for better grip comfort.

Maintenance and Cleaning Requirements

Aluminum pots require frequent polishing to prevent oxidation and maintain their appearance, while carbon steel pots develop a natural non-stick patina with proper seasoning. Cleaning aluminum pots demands gentle detergents to avoid surface damage, whereas carbon steel pots should be cleaned without soap to preserve the seasoning layer. Both materials benefit from thorough drying after boiling to prevent corrosion and extend cookware lifespan.

Cost Comparison: Affordability for Home Cooks

Aluminum pots are generally more affordable than carbon steel pots, making them a popular choice for budget-conscious home cooks. However, carbon steel offers greater durability, which may justify its higher initial cost over time.

- Initial Cost Advantage - Aluminum pots typically cost 20-30% less than carbon steel alternatives, lowering upfront expenses.

- Long-Term Investment - Carbon steel pots withstand frequent boiling and high heat without warping, reducing replacement frequency.

- Value for Money - While aluminum is cheaper initially, carbon steel's longevity can provide better overall value for boiling tasks.

Related Important Terms

Thermal Conductivity Differential

Aluminum pots, with a thermal conductivity of approximately 237 W/m*K, heat water faster and more evenly during boiling compared to carbon steel pots, which have a lower thermal conductivity around 50 W/m*K. This significant difference means aluminum pots require less energy and time to reach boiling point, enhancing cooking efficiency and heat distribution.

Rapid Heat-Up Lag

Carbon steel pots exhibit a shorter rapid heat-up lag compared to aluminum pots due to their higher thermal conductivity, enabling faster boiling times. This efficiency in heat transfer reduces energy consumption and accelerates cooking processes, making carbon steel ideal for tasks requiring quick heat adjustments.

Re-boil Recovery Rate

Carbon steel pots exhibit a higher re-boil recovery rate compared to aluminum pots due to their superior heat retention and thermal conductivity, allowing water to reach boiling temperature faster after heat application is reintroduced. Aluminum pots, although lightweight and corrosion-resistant, tend to lose heat more quickly, resulting in slower re-boil recovery and less efficient heat utilization during the boiling process.

Aluminum Ion Migration

Aluminum pots tend to release aluminum ions into boiling water, which may raise health concerns compared to carbon steel pots that exhibit minimal ion migration due to their stable iron composition. Boiling in carbon steel pots reduces the risk of aluminum ingestion and provides better durability under high temperatures.

Steel Leaching Integrity

Carbon steel pots demonstrate superior steel leaching integrity compared to aluminum pots during boiling, as they are less prone to releasing metal ions into the water. Aluminum pots, while lightweight and conductive, may leach aluminum ions, especially when boiling acidic or alkaline substances, potentially affecting both taste and health.

Boil Over Tolerance

Carbon steel pots exhibit higher boil over tolerance compared to aluminum pots due to their superior thermal conductivity and sturdier structure, effectively managing rapid temperature changes without spilling. Aluminum pots, while lightweight and quick to heat, often have lower boil over tolerance, making them more prone to spills during vigorous boiling.

Warp Resistance Boiling

Carbon steel pots offer superior warp resistance during boiling due to their higher structural rigidity and better thermal conductivity, maintaining shape even under rapid temperature changes. Aluminum pots, while excellent in heat distribution, are more prone to warping from prolonged exposure to boiling temperatures and sudden thermal shocks.

Oxide Layer Retention

Aluminum pots form a stable oxide layer that enhances corrosion resistance but can degrade under high heat, potentially impacting longevity when boiling acidic or salty liquids. Carbon steel pots develop a protective iron oxide layer that strengthens with use and high temperature, maintaining durability and non-stick properties during prolonged boiling.

Induction Compatibility Factor

Aluminum pots generally exhibit poor induction compatibility due to their non-ferromagnetic nature, requiring a magnetic base or disk for induction cooktops, whereas carbon steel pots are inherently ferromagnetic, providing excellent induction compatibility and efficient heat transfer. This makes carbon steel pots preferable for induction boiling applications, ensuring quicker heating times and energy efficiency.

Aluminum pot vs Carbon steel pot for boiling. Infographic

cookingdiff.com

cookingdiff.com