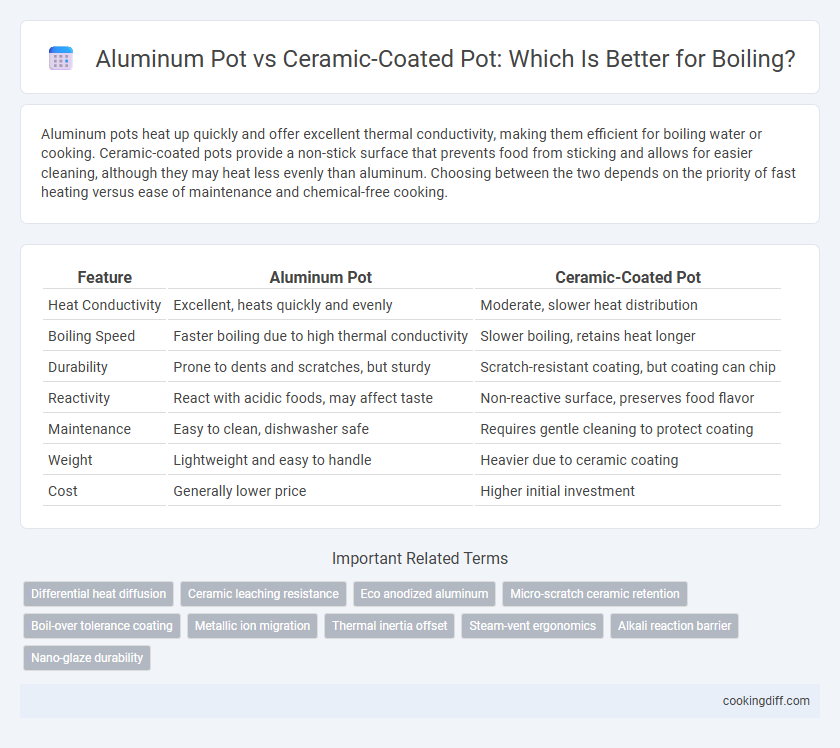

Aluminum pots heat up quickly and offer excellent thermal conductivity, making them efficient for boiling water or cooking. Ceramic-coated pots provide a non-stick surface that prevents food from sticking and allows for easier cleaning, although they may heat less evenly than aluminum. Choosing between the two depends on the priority of fast heating versus ease of maintenance and chemical-free cooking.

Table of Comparison

| Feature | Aluminum Pot | Ceramic-Coated Pot |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, slower heat distribution |

| Boiling Speed | Faster boiling due to high thermal conductivity | Slower boiling, retains heat longer |

| Durability | Prone to dents and scratches, but sturdy | Scratch-resistant coating, but coating can chip |

| Reactivity | React with acidic foods, may affect taste | Non-reactive surface, preserves food flavor |

| Maintenance | Easy to clean, dishwasher safe | Requires gentle cleaning to protect coating |

| Weight | Lightweight and easy to handle | Heavier due to ceramic coating |

| Cost | Generally lower price | Higher initial investment |

Introduction: Aluminum vs Ceramic-Coated Pots for Boiling

Aluminum pots heat up quickly and provide excellent thermal conductivity, making them efficient for boiling water. Ceramic-coated pots offer a non-reactive surface, preventing any metallic taste from leaching into food during boiling. While aluminum pots are lightweight and affordable, ceramic-coated options tend to be more durable and easier to clean after boiling tasks.

Heat Conductivity: Which Pot Boils Faster?

Aluminum pots have superior heat conductivity compared to ceramic-coated pots, allowing them to boil water faster due to rapid heat transfer. Ceramic-coated pots tend to heat more slowly as the coating acts as an insulating layer, reducing thermal efficiency.

- Aluminum's Heat Conductivity - Aluminum conducts heat at approximately 237 W/m*K, enabling quick temperature rises.

- Ceramic Coating Insulation - The ceramic layer has lower thermal conductivity, slowing heat transfer to the pot's contents.

- Boiling Time Impact - The higher thermal conductivity of aluminum results in significantly reduced boiling times compared to ceramic-coated pots.

Choosing an aluminum pot ensures faster boiling due to its efficient heat conduction properties.

Durability and Longevity in Boiling Applications

Aluminum pots offer excellent heat conductivity, making them efficient for boiling, but they may degrade over time due to oxidation and warping with frequent high-temperature use. In contrast, ceramic-coated pots provide a durable non-reactive surface that resists scratches and chemical breakdown, extending their longevity in boiling applications.

While aluminum pots are lightweight and affordable, their durability decreases significantly if not properly maintained or if used with acidic foods. Ceramic-coated pots maintain consistent performance and structural integrity longer, making them a preferred choice for users prioritizing long-term use in boiling tasks.

Safety Concerns: Leaching and Toxicity Risks

Aluminum pots can pose safety concerns due to potential leaching of aluminum ions into food during boiling, especially with acidic or salty ingredients, which may contribute to health risks over prolonged exposure. Ceramic-coated pots offer a non-reactive surface that minimizes the risk of metal leaching, making them safer for boiling various foods.

However, the durability of ceramic coatings is crucial; if the coating is damaged or scratched, underlying metals could leach into food, raising toxicity concerns. Proper maintenance and inspection of ceramic-coated cookware ensure safety and reduce the risk of harmful substance exposure during boiling.

Maintenance and Cleaning After Boiling

Aluminum pots often require thorough scrubbing to remove mineral deposits and discoloration after boiling, while ceramic-coated pots typically clean easily with mild detergents and avoid staining. Proper maintenance ensures the aluminum does not oxidize, whereas ceramic coatings need gentle care to prevent chipping and maintain their non-stick surface.

- Aluminum pots develop oxide layers - Regular cleaning with non-abrasive scrubbers helps maintain surface integrity and prevent corrosion.

- Ceramic-coated pots resist staining - Washing with soft sponges preserves the coating's smooth texture and prolongs durability.

- Boiling minerals accumulate differently - Aluminum reacts to hard water deposits requiring more frequent descaling compared to ceramic coatings.

Cost Comparison: Aluminum Pot vs Ceramic-Coated Pot

Which option is more cost-effective for boiling: an aluminum pot or a ceramic-coated pot? Aluminum pots are generally more affordable, with prices starting as low as $10, making them a budget-friendly choice. Ceramic-coated pots tend to be pricier, often ranging from $30 to $70, but they offer a non-stick surface that may reduce cooking oil use and extend the pot's lifespan.

Flavor Impact: Do Pots Affect the Taste of Boiled Foods?

Aluminum pots may slightly affect the taste of boiled foods due to potential metal leaching, especially with acidic ingredients. Ceramic-coated pots provide a neutral surface that preserves the original flavors without imparting any metallic taste.

- Aluminum Reactivity - Aluminum can react with acidic foods, causing a metallic flavor to develop during boiling.

- Ceramic Coating Neutrality - Ceramic coatings create a non-reactive barrier that prevents flavor alteration in boiled dishes.

- Flavor Preservation - Using ceramic-coated pots ensures that boiled foods retain their intended taste profile without contamination.

Suitability for Different Types of Boiling

Aluminum pots heat up quickly and are ideal for rapid boiling tasks like pasta or vegetables due to their excellent thermal conductivity. Ceramic-coated pots provide a non-reactive surface, making them suitable for boiling acidic foods such as tomato-based sauces without metallic taste transfer.

For prolonged boiling, ceramic-coated pots retain heat evenly and reduce the risk of hot spots, preventing food from burning or sticking. Aluminum pots, while efficient for quick boiling, may warp under extended high heat and can react with acidic ingredients. Choosing between the two depends on the specific boiling requirement and the type of food being prepared.

Energy Efficiency in Boiling Tasks

Aluminum pots offer superior thermal conductivity, allowing water to reach boiling point faster and reducing overall energy consumption during boiling. Ceramic-coated pots, while providing a non-stick surface, have thicker walls that retain heat but require more time and energy to achieve boiling temperatures. Choosing aluminum cookware can enhance energy efficiency in boiling tasks by minimizing heat loss and cooking duration.

Related Important Terms

Differential heat diffusion

Aluminum pots exhibit rapid and even heat diffusion due to aluminum's high thermal conductivity of approximately 237 W/m*K, enabling quicker boiling times and uniform temperature distribution. Ceramic-coated pots, while offering non-stick benefits and corrosion resistance, have lower thermal conductivity around 1.5 W/m*K, resulting in slower heat diffusion and less efficient boiling compared to aluminum cookware.

Ceramic leaching resistance

Ceramic-coated pots exhibit superior resistance to leaching harmful substances compared to aluminum pots, making them safer for boiling acidic or mineral-rich liquids. Their inert ceramic layer prevents metal ions from contaminating food, ensuring cleaner and healthier boiling outcomes.

Eco anodized aluminum

Eco anodized aluminum pots offer superior heat conductivity and durability compared to ceramic-coated pots, enabling faster boiling times and improved energy efficiency. Their non-toxic, scratch-resistant surfaces avoid chemical leaching, making them a safer and more sustainable option for boiling water and cooking.

Micro-scratch ceramic retention

Aluminum pots heat quickly due to high thermal conductivity but often lack durability when it comes to surface integrity, causing faster micro-scratch accumulation. Ceramic-coated pots excel in retaining their micro-scratch resistance, preserving the non-stick and hygienic qualities essential for consistent and safe boiling performance.

Boil-over tolerance coating

Aluminum pots typically offer superior heat conductivity but lack a specialized boil-over tolerance coating, making them more prone to spills and residue buildup during rapid boiling. Ceramic-coated pots provide enhanced boil-over tolerance with their non-porous surface, preventing overflow messes and facilitating easier cleanup while maintaining consistent heat distribution.

Metallic ion migration

Aluminum pots are prone to metallic ion migration during boiling, which can leach aluminum ions into food, potentially raising health concerns. Ceramic-coated pots minimize metallic ion transfer due to their non-reactive surface, offering a safer alternative for boiling acidic or alkaline liquids.

Thermal inertia offset

Aluminum pots offer low thermal inertia, enabling rapid temperature changes and efficient boiling with minimal heat retention, while ceramic-coated pots have higher thermal inertia, causing slower heat response but maintaining heat longer. This thermal inertia offset affects boiling precision and energy consumption, with aluminum pots providing quicker temperature control and ceramic-coated pots ensuring more even, sustained heat distribution.

Steam-vent ergonomics

Aluminum pots heat rapidly and provide consistent steam release through well-designed vents, enhancing ergonomic handling during boiling tasks. Ceramic-coated pots offer slower heat conduction but feature built-in steam vents that reduce pressure build-up, improving safety and user comfort.

Alkali reaction barrier

Aluminum pots often react with alkaline substances during boiling, potentially altering the taste and leaching metals into the liquid, whereas ceramic-coated pots provide a robust alkali reaction barrier that prevents such interactions and ensures safer cooking. This non-reactive ceramic coating enhances durability and maintains the purity of boiled water or food, making it an optimal choice for acidic or alkaline cooking environments.

Aluminum pot vs ceramic-coated pot for boiling. Infographic

cookingdiff.com

cookingdiff.com