Aluminum pots heat up quickly and offer excellent heat conductivity, making them ideal for boiling water efficiently while being lightweight and affordable. Copper core pots provide superior heat distribution and precise temperature control, reducing hot spots and ensuring even boiling. Choosing between aluminum and copper core depends on prioritizing fast heating and cost or enhanced durability and cooking performance.

Table of Comparison

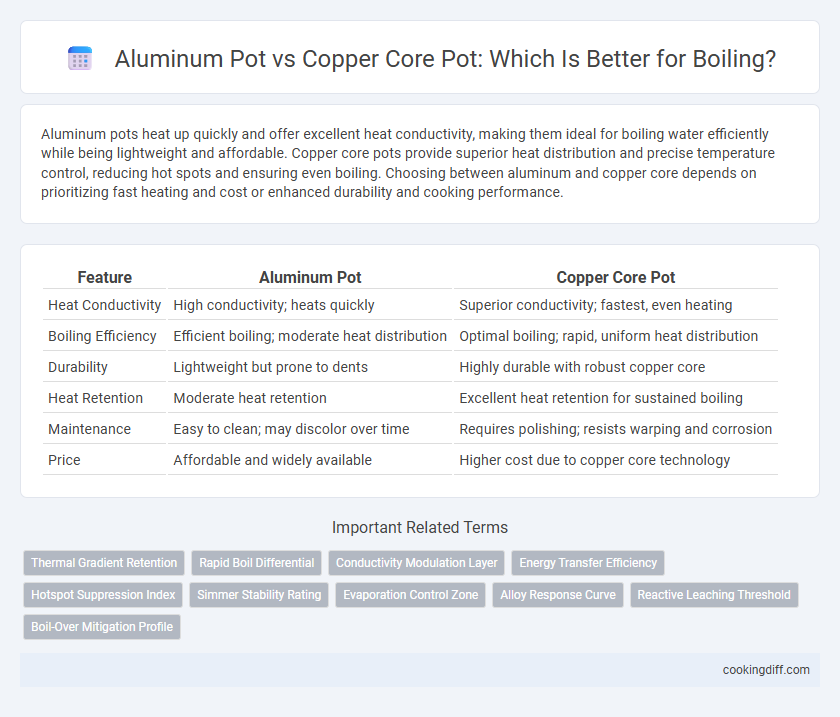

| Feature | Aluminum Pot | Copper Core Pot |

|---|---|---|

| Heat Conductivity | High conductivity; heats quickly | Superior conductivity; fastest, even heating |

| Boiling Efficiency | Efficient boiling; moderate heat distribution | Optimal boiling; rapid, uniform heat distribution |

| Durability | Lightweight but prone to dents | Highly durable with robust copper core |

| Heat Retention | Moderate heat retention | Excellent heat retention for sustained boiling |

| Maintenance | Easy to clean; may discolor over time | Requires polishing; resists warping and corrosion |

| Price | Affordable and widely available | Higher cost due to copper core technology |

Introduction to Boiling with Different Pots

Boiling efficiency varies significantly between aluminum pots and copper core pots due to their distinct thermal conductivity properties. Understanding how each material responds to heat can optimize cooking performance and energy usage.

- Aluminum Pot - Offers rapid heat distribution, making it ideal for quick boiling tasks.

- Copper Core Pot - Provides superior thermal conductivity, ensuring even heat and temperature control.

- Boiling Performance - Copper core pots generally maintain consistent boil, while aluminum pots heat faster but may create hot spots.

Material Composition: Aluminum vs Copper Core

Aluminum pots offer excellent heat conduction due to their lightweight and high thermal conductivity, allowing water to reach boiling temperatures quickly and evenly. This material also resists corrosion, making it a durable and cost-effective option for everyday boiling tasks.

Copper core pots feature a layer of copper sandwiched between stainless steel or aluminum, maximizing heat distribution and precise temperature control during boiling. The copper core efficiently spreads heat across the pot's surface, reducing hotspots and ensuring consistent boiling performance.

Heat Conductivity and Boiling Efficiency

Which pot offers better boiling efficiency, an aluminum pot or a copper core pot? Copper core pots provide superior heat conductivity, allowing water to reach boiling point faster and ensuring even heat distribution. Aluminum pots heat up quickly but often result in uneven boiling due to lower thermal conductivity compared to copper cores.

Durability and Longevity in Boiling Applications

| Aluminum Pot | Aluminum pots offer excellent heat conductivity but are prone to warping and pitting under prolonged boiling conditions, reducing durability over time. They often require anodization or coating to enhance resistance to corrosion and wear during continuous exposure to boiling water. Regular maintenance extends lifespan, but uncoated aluminum can degrade faster in high-temperature boiling applications. |

| Copper Core Pot | Copper core pots provide superior heat distribution and maintain structural integrity longer under frequent boiling due to copper's high thermal conductivity and stability. They resist deformation and corrosion better than aluminum, contributing to greater durability and prolonged effective use. The copper core, combined with protective layers, ensures longevity despite continuous exposure to boiling temperatures. |

Weight and Handling During Boiling

Aluminum pots are lightweight, making them easier to handle during boiling, especially when full of hot liquid. Copper core pots tend to be heavier due to the dense copper layer, impacting maneuverability on the stove.

The lighter weight of aluminum pots reduces strain on wrists when lifting or pouring, ideal for frequent boiling tasks. Copper core pots offer superior heat conductivity but require more careful handling to avoid spills due to their additional weight. For precise temperature control, copper pots often necessitate steadier grips during boiling.

Reactivity with Food While Boiling

Aluminum pots react more readily with acidic foods during boiling, potentially causing metallic flavors and discoloration of the food due to aluminum leaching. Copper core pots contain a stainless steel inner layer that prevents direct contact between copper and food, minimizing reactivity and preserving flavor integrity.

The non-reactive surface of copper core pots makes them ideal for boiling acidic ingredients like tomatoes or vinegar-based sauces without altering taste. Aluminum's higher reactivity requires careful use with acidic foods to avoid nutrient loss and undesirable color changes during cooking.

Maintenance and Cleaning Requirements

Aluminum pots require careful cleaning to avoid discoloration and maintain their non-stick properties, while copper core pots need regular polishing to prevent tarnish and retain their heat conductivity. Both materials demand specific maintenance routines to ensure longevity and optimal boiling performance.

- Aluminum Reactivity - Aluminum is reactive with acidic foods and cleansers, requiring gentle washing to avoid damage.

- Copper Tarnish - Copper cores develop patina over time and need consistent polishing to maintain shine and effectiveness.

- Durability Concerns - Aluminum pots can warp under high heat if not properly maintained, whereas copper core pots resist deformation but require more effort in upkeep.

Choosing between aluminum and copper core pots depends on your willingness to follow specific maintenance and cleaning routines for boiling efficiency.

Cost Comparison: Aluminum vs Copper Core Pots

Aluminum pots offer a budget-friendly option with decent heat conduction, ideal for everyday boiling needs. Copper core pots, while more expensive, provide superior heat distribution and durability that justifies the higher investment.

- Cost Efficiency - Aluminum pots are significantly cheaper, making them accessible for cost-conscious buyers.

- Heat Performance - Copper core pots enhance boiling efficiency due to better thermal conductivity.

- Longevity - Copper core pots tend to last longer, offering better value over time despite the upfront cost.

Boiling Performance in Everyday Cooking

Aluminum pots offer rapid heat conduction, ensuring water reaches boiling point quickly, which enhances energy efficiency in everyday cooking. Copper core pots provide superior temperature control and even heat distribution, reducing hotspots and preventing uneven boiling. For consistent boiling performance, copper core pots maintain stable temperatures, making them ideal for delicate recipes requiring precise heat management.

Related Important Terms

Thermal Gradient Retention

Copper core pots excel in thermal gradient retention due to copper's superior thermal conductivity of approximately 401 W/m*K, enabling faster and more even heat distribution compared to aluminum pots, which have a conductivity of around 237 W/m*K. This efficient heat retention minimizes hotspots and maintains consistent boiling temperatures, making copper core pots ideal for precision cooking and energy efficiency.

Rapid Boil Differential

Copper core pots achieve rapid boil times significantly faster than aluminum pots due to copper's superior thermal conductivity, which enables heat to distribute evenly and swiftly across the cooking surface. Aluminum pots, while lightweight and cost-effective, generally take longer to reach boiling point because their lower thermal conductivity results in slower heat transfer.

Conductivity Modulation Layer

Copper core pots feature a superior conductivity modulation layer that enhances rapid and even heat distribution during boiling, minimizing hotspots and reducing energy consumption. Aluminum pots, while lightweight and corrosion-resistant, lack this advanced layer, resulting in slower heat transfer and less consistent boiling performance.

Energy Transfer Efficiency

Copper core pots exhibit superior energy transfer efficiency compared to aluminum pots due to copper's higher thermal conductivity of approximately 401 W/m*K, enabling faster and more even heat distribution during boiling. Aluminum pots, with a thermal conductivity around 237 W/m*K, heat quickly but tend to have less uniform heat transfer, often resulting in energy loss and uneven cooking.

Hotspot Suppression Index

Copper core pots outperform aluminum pots in boiling due to a higher Hotspot Suppression Index, which ensures more even heat distribution and prevents localized overheating. This efficient thermal conductivity minimizes scorching and promotes consistent boiling temperatures across the pot's surface.

Simmer Stability Rating

Copper core pots offer superior simmer stability ratings compared to aluminum pots due to copper's excellent thermal conductivity and responsiveness to heat adjustments. This results in more precise temperature control during boiling, reducing the risk of scorching or uneven cooking.

Evaporation Control Zone

Copper core pots provide superior heat conductivity and precise temperature control within the evaporation control zone, allowing for consistent simmering without excessive steam loss. Aluminum pots heat quickly but tend to create uneven temperature distribution, making it harder to maintain stable evaporation rates during boiling.

Alloy Response Curve

Aluminum pots heat quickly and provide efficient boiling due to their high thermal conductivity, but their performance follows a steeper alloy response curve, meaning minor alloy variations significantly impact heat distribution. Copper core pots exhibit more stable boiling temperatures with a flatter alloy response curve, ensuring consistent heat transfer and precise temperature control during boiling.

Reactive Leaching Threshold

Aluminum pots have a lower reactive leaching threshold compared to copper core pots, making them more prone to releasing aluminum ions into food during boiling, especially with acidic ingredients. Copper core pots maintain structural integrity with minimal leaching due to their stable copper-aluminum interface, providing safer and more durable cookware for high-temperature boiling.

Aluminum Pot vs Copper Core Pot for boiling. Infographic

cookingdiff.com

cookingdiff.com