An aluminum pot heats up quickly and distributes heat evenly, making it ideal for efficient boiling. However, it is not induction-compatible due to its non-magnetic properties, which means it cannot be used on induction cooktops without a magnetic base. In contrast, induction-compatible pots, often made from stainless steel or with a magnetic layer, are specifically designed for induction cooktops, offering precise temperature control and energy-efficient boiling.

Table of Comparison

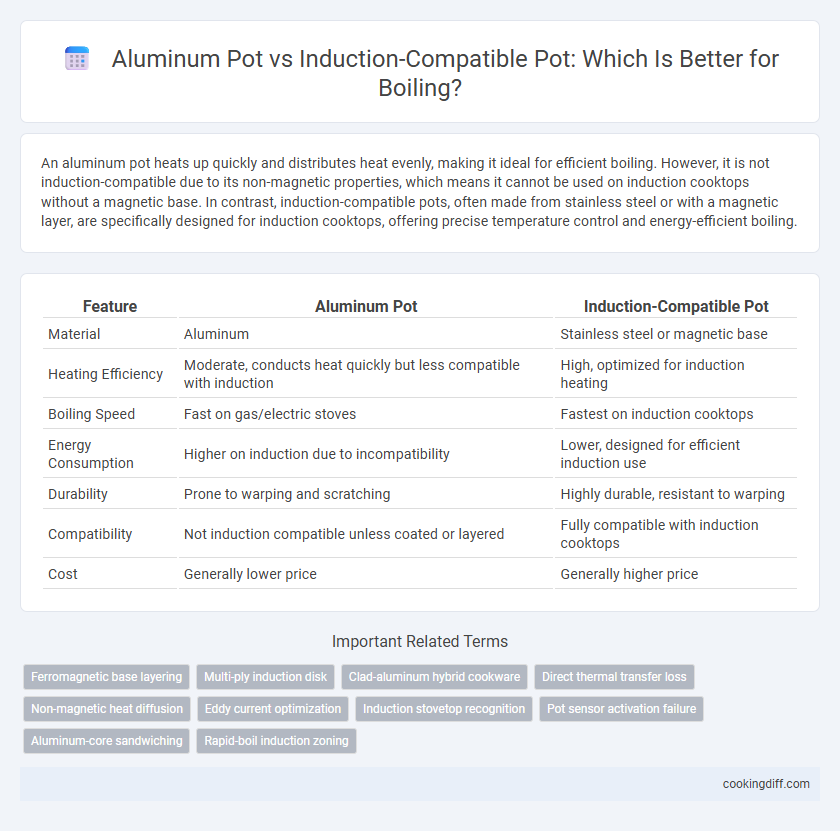

| Feature | Aluminum Pot | Induction-Compatible Pot |

|---|---|---|

| Material | Aluminum | Stainless steel or magnetic base |

| Heating Efficiency | Moderate, conducts heat quickly but less compatible with induction | High, optimized for induction heating |

| Boiling Speed | Fast on gas/electric stoves | Fastest on induction cooktops |

| Energy Consumption | Higher on induction due to incompatibility | Lower, designed for efficient induction use |

| Durability | Prone to warping and scratching | Highly durable, resistant to warping |

| Compatibility | Not induction compatible unless coated or layered | Fully compatible with induction cooktops |

| Cost | Generally lower price | Generally higher price |

Introduction: Understanding Boiling Pot Materials

Boiling efficiency depends significantly on the material of the pot used, with aluminum and induction-compatible pots offering distinct thermal properties. Aluminum pots provide excellent heat conductivity, reducing boiling time by distributing heat evenly across the surface.

Induction-compatible pots usually feature ferromagnetic stainless steel or have a magnetic base, enabling direct heat generation through induction for rapid boiling. While aluminum pots excel in traditional stovetop use with quick heat response, induction-compatible pots deliver precise temperature control and energy efficiency on induction cooktops. Understanding these material differences helps optimize boiling performance based on the cooking technology employed.

Aluminum Pots: Benefits and Drawbacks for Boiling

Aluminum pots offer excellent thermal conductivity, allowing water to boil quickly and evenly. However, they are not induction-compatible without a magnetic base, limiting their use on induction cooktops.

- Fast Heating - Aluminum distributes heat rapidly, reducing boiling times effectively.

- Non-Induction Compatible - Pure aluminum lacks magnetic properties, making it unusable on standard induction stoves.

- Lightweight - Aluminum pots are easy to handle due to their low weight, enhancing kitchen convenience.

Choosing aluminum pot for boiling depends on the type of stovetop and preference for quick heat conduction.

Induction-Compatible Pots: Key Features for Boiling

Induction-compatible pots feature a magnetic base made from ferrous materials like stainless steel or cast iron, ensuring efficient heat transfer on induction cooktops. These pots provide rapid boiling times due to uniform heat distribution and minimal energy loss.

They often include layered bottoms with aluminum cores to enhance conductivity while maintaining compatibility with induction technology. Their durability and resistance to warping under high temperatures make them ideal for consistent boiling tasks.

Heating Efficiency: Aluminum vs Induction-Compatible Pots

Aluminum pots offer excellent thermal conductivity, allowing water to reach boiling point quickly, making them energy-efficient for traditional stovetops. Induction-compatible pots, typically made from magnetic stainless steel or cast iron, heat up faster on induction ranges by directly transferring electromagnetic energy to the pot.

- Aluminum Thermal Conductivity - Aluminum's high thermal conductivity ensures rapid and even heat distribution, reducing boiling times on gas or electric stoves.

- Induction Heating Mechanism - Induction-compatible pots rely on electromagnetic fields that heat the pot directly, minimizing heat loss and increasing energy efficiency.

- Energy Efficiency Comparison - Induction pots generally offer superior energy efficiency by heating only the pot, while aluminum pots may lose heat to the surrounding environment on non-induction heat sources.

Boiling Speed Comparison: Which Pot is Faster?

Which pot boils water faster, an aluminum pot or an induction-compatible pot? Induction-compatible pots, typically made of magnetic stainless steel, heat water more quickly due to direct electromagnetic energy transfer, while aluminum pots rely on traditional conduction. This makes induction pots significantly faster in boiling compared to aluminum pots on induction cooktops.

Heat Distribution: Consistency in Aluminum and Induction Pots

Aluminum pots offer excellent heat distribution due to their high thermal conductivity, allowing water to boil evenly and quickly. This consistency reduces hot spots and prevents uneven cooking during boiling tasks.

Induction-compatible pots, typically made with a magnetic stainless steel base, provide precise heat control and maintain consistent temperature throughout boiling. Their construction ensures efficient energy transfer, resulting in reliable and uniform boiling performance.

Safety Considerations: Boiling on Different Cooktops

Boiling water in an aluminum pot on an induction cooktop is ineffective because aluminum is not naturally induction-compatible, leading to uneven heating and potential safety risks like overheating. Induction-compatible pots, usually made with magnetic stainless steel or cast iron, ensure rapid and precise temperature control, minimizing the risk of burns or accidents. Using the correct pot type enhances safety by preventing cookware damage and maintaining stable boiling temperatures on induction cooktops.

Durability and Maintenance: Aluminum vs Induction Pots

Aluminum pots offer excellent heat conductivity but tend to warp and discolor over time due to frequent exposure to high boiling temperatures. Induction-compatible pots, typically made from stainless steel or cast iron, provide superior durability and resist corrosion and warping under intense heat.

- Aluminum susceptibility - Aluminum pots can degrade faster when exposed to acidic foods and high temperatures during boiling.

- Induction pot resilience - Induction-compatible pots maintain structural integrity longer due to robust materials designed for high-heat cooking.

- Maintenance demands - Aluminum requires careful cleaning to prevent oxidation, while induction pots are generally easier to maintain with their non-reactive surfaces.

Cost Analysis: Price Differences for Boiling Pots

Aluminum pots generally cost less than induction-compatible pots, making them a budget-friendly option for boiling tasks. Induction-compatible pots, often made with stainless steel or a magnetic base, have a higher upfront price but offer greater energy efficiency and faster heating. Over time, the energy savings and durability of induction-compatible pots may offset their initial higher cost compared to aluminum options.

Related Important Terms

Ferromagnetic base layering

Aluminum pots lack a ferromagnetic base layer, making them incompatible with induction cooktops, which require magnetic materials for efficient heat transfer. Induction-compatible pots feature a ferromagnetic base, typically composed of stainless steel or iron layers, enabling rapid, even boiling by generating heat directly through electromagnetic induction.

Multi-ply induction disk

Multi-ply induction disks enhance heat distribution and retention in aluminum pots, significantly improving boiling efficiency compared to standard induction-compatible pots. The layered construction of these disks ensures rapid, even heating, reducing energy consumption and preventing hot spots during boiling.

Clad-aluminum hybrid cookware

Clad-aluminum hybrid cookware offers superior heat conductivity and rapid boiling times compared to traditional aluminum pots, while being fully compatible with induction cooktops due to their magnetic stainless steel layers. This combination ensures even heat distribution, energy efficiency, and durability, making them ideal for precise temperature control during boiling tasks.

Direct thermal transfer loss

Aluminum pots exhibit superior direct thermal transfer due to their high thermal conductivity of approximately 205 W/m*K, minimizing heat loss during boiling. Induction-compatible pots, often made with stainless steel layers, have lower conductivity around 16 W/m*K, resulting in slower heat transfer and greater direct thermal transfer loss.

Non-magnetic heat diffusion

Aluminum pots offer superior non-magnetic heat diffusion due to their excellent thermal conductivity, enabling rapid and even boiling without hotspots. Induction-compatible pots, generally made from magnetic stainless steel or cast iron, rely on magnetic fields but often provide slower, less uniform heat distribution compared to aluminum cookware.

Eddy current optimization

Aluminum pots exhibit lower eddy current losses due to their high electrical conductivity but lack magnetic properties, resulting in inefficient heating on induction cooktops. Induction-compatible pots, often made from ferromagnetic stainless steel or cast iron, optimize eddy current generation by maximizing magnetic flux coupling, thereby achieving faster and more energy-efficient boiling on induction surfaces.

Induction stovetop recognition

Induction-compatible pots feature a magnetic base essential for efficient heat transfer and accurate stovetop recognition, whereas standard aluminum pots lack this property, preventing them from activating induction burners. Choosing an induction-compatible pot ensures rapid boiling times and energy-efficient cooking on induction stovetops.

Pot sensor activation failure

Aluminum pots often fail to activate induction cooktop sensors due to their non-magnetic properties, resulting in inefficient heating or no heat generation. Induction-compatible pots with ferromagnetic bases ensure reliable sensor activation, leading to faster and more energy-efficient boiling performance.

Aluminum-core sandwiching

Aluminum-core sandwiching in pots enhances heat conductivity and distribution, making aluminum-core induction-compatible pots ideal for boiling as they heat faster and more evenly than pure aluminum pots. This design minimizes hot spots and energy wastage, providing efficient boiling performance on induction cooktops.

Aluminum pot vs Induction-compatible pot for boiling. Infographic

cookingdiff.com

cookingdiff.com