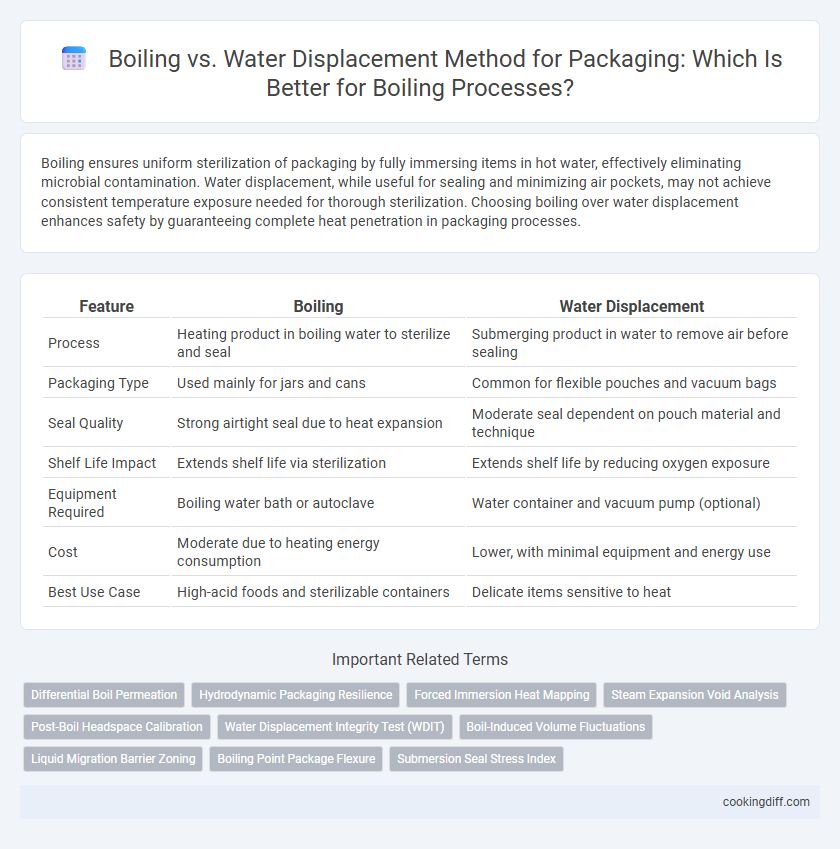

Boiling ensures uniform sterilization of packaging by fully immersing items in hot water, effectively eliminating microbial contamination. Water displacement, while useful for sealing and minimizing air pockets, may not achieve consistent temperature exposure needed for thorough sterilization. Choosing boiling over water displacement enhances safety by guaranteeing complete heat penetration in packaging processes.

Table of Comparison

| Feature | Boiling | Water Displacement |

|---|---|---|

| Process | Heating product in boiling water to sterilize and seal | Submerging product in water to remove air before sealing |

| Packaging Type | Used mainly for jars and cans | Common for flexible pouches and vacuum bags |

| Seal Quality | Strong airtight seal due to heat expansion | Moderate seal dependent on pouch material and technique |

| Shelf Life Impact | Extends shelf life via sterilization | Extends shelf life by reducing oxygen exposure |

| Equipment Required | Boiling water bath or autoclave | Water container and vacuum pump (optional) |

| Cost | Moderate due to heating energy consumption | Lower, with minimal equipment and energy use |

| Best Use Case | High-acid foods and sterilizable containers | Delicate items sensitive to heat |

Introduction to Boiling and Water Displacement in Food Packaging

Boiling and water displacement are common methods used in food packaging to eliminate air and ensure product preservation. Boiling involves immersing containers in boiling water to sterilize and seal food, while water displacement uses the liquid's pressure to remove air by submerging the container in water before sealing.

Boiling effectively kills bacteria and extends shelf life by applying high heat, ideal for canning fruits and vegetables. Water displacement reduces oxygen exposure without high heat, preserving delicate textures and flavors in products like pickles and fermented foods. Both methods enhance food safety and quality, but selecting the appropriate technique depends on the food type and packaging requirements.

How Boiling Affects Food Packaging Integrity

Boiling can compromise food packaging integrity by causing heat-induced material deformation or seal failure, leading to potential contamination risks. In contrast, water displacement maintains package structure by gently removing air without subjecting packaging to high temperatures.

- Heat Exposure Impact - Boiling subjects packaging materials to temperatures above 100degC, risking warping or melting of plastic components.

- Seal Strength Reduction - Prolonged boiling can weaken adhesive seals, increasing the likelihood of leaks and spoilage.

- Water Displacement Advantage - Using water displacement avoids direct heat, preserving the physical and functional integrity of flexible packaging.

Understanding Water Displacement Techniques

Water displacement techniques measure the volume of irregular objects by submerging them in water and observing the change in water level, providing precise volume determination for packaging. This method is particularly effective when packaging materials require exact volume calculations to optimize space and reduce air pockets.

Boiling, while primarily a cooking process, is sometimes compared to water displacement in packaging for its role in temperature and volume changes during sterilization. Understanding water displacement ensures accurate packaging specifications, whereas boiling affects material properties that may impact packaging integrity.

Advantages of Boiling for Package Sealing

Boiling offers precise temperature control essential for effective package sealing, ensuring consistent sterilization and reducing the risk of contamination. This method enhances seal integrity by evenly heating the packaging material, preventing leaks and preserving product freshness. Unlike water displacement, boiling provides a reliable and straightforward approach without the need for specialized equipment or complex procedures.

Benefits of Water Displacement for Air Removal

Water displacement effectively removes air from packaging, reducing oxidation and spoilage compared to boiling methods. This technique enhances product shelf life by creating a vacuum-like environment without the risks associated with heat exposure.

- Enhanced air removal - Water displacement displaces trapped air more thoroughly than boiling, minimizing oxygen contact.

- Improved product quality - Lower oxygen exposure reduces spoilage and preserves flavor and texture.

- Energy efficiency - Water displacement requires less energy than boiling, promoting sustainable packaging processes.

Comparing Food Safety: Boiling vs Water Displacement

Which method offers better food safety: boiling or water displacement for packaging? Boiling effectively eliminates harmful bacteria and pathogens due to consistent high temperatures, ensuring sterile food packaging. Water displacement reduces air exposure but may not reach temperatures necessary for complete pathogen elimination, making it less reliable for food safety compared to boiling.

Impact on Shelf Life: Which Method Prevails?

| Boiling | Effectively eliminates pathogens, extending shelf life by reducing microbial load in packaging processes. |

| Water Displacement | Minimizes air exposure, reducing oxidation but may not fully eradicate microbes, potentially limiting shelf life extension. |

| Shelf Life Impact | Boiling generally prevails by providing superior microbial control, resulting in longer preservation compared to water displacement. |

Suitability for Different Food Types

Boiling is ideal for packaging foods that require uniform heat penetration, such as vegetables and pasta, ensuring even cooking and maintaining texture. It works well with products needing sterilization without altering shape or volume significantly.

Water displacement suits delicate and irregularly shaped foods like berries or leafy greens, minimizing air pockets and preserving visual appeal. This method reduces oxidation and helps maintain product freshness during packaging and storage.

Environmental Considerations: Water Use and Energy

Boiling consumes significantly more water and energy compared to water displacement methods used in packaging. Water displacement techniques minimize environmental impact by reducing resource consumption during the process.

- Water Consumption - Boiling requires large volumes of water to maintain temperature and volume, increasing water use.

- Energy Efficiency - Water displacement operates at ambient temperatures, thus lowering energy demands substantially.

- Environmental Footprint - Reduced water and energy consumption from water displacement lead to a smaller carbon footprint.

Choosing water displacement over boiling supports sustainable packaging practices by optimizing resource efficiency.

Related Important Terms

Differential Boil Permeation

Boiling leverages high-temperature vaporization to achieve uniform sterilization through Differential Boil Permeation, ensuring consistent microbial reduction across packaging layers. Water displacement methods often lack the precision of controlling permeation rates, resulting in less effective sterilization and potential packaging integrity compromise.

Hydrodynamic Packaging Resilience

Boiling enhances hydrodynamic packaging resilience by uniformly increasing water temperature, which minimizes thermal shocks and maintains package integrity under pressure. Water displacement methods may introduce air pockets that compromise packaging stability and reduce resistance to hydrodynamic stress during transport.

Forced Immersion Heat Mapping

Forced immersion heat mapping during boiling provides precise temperature distribution data critical for validating sterilization cycles, outperforming water displacement methods that often yield less accurate thermal profiles due to uneven heat transfer. This accuracy ensures packaging integrity by confirming consistent heat penetration, crucial for food safety and extending shelf life.

Steam Expansion Void Analysis

Steam expansion void analysis during boiling provides precise measurement of void volume created by steam pressure, offering superior accuracy over water displacement methods that may underestimate voids due to liquid adhesion or incomplete filling. Boiling leverages rapid phase change and volumetric expansion of steam to clearly reveal micro-voids in packaging, enhancing defect detection critical for quality control.

Post-Boil Headspace Calibration

Post-boil headspace calibration ensures accurate measurement of container volume by compensating for thermal expansion during boiling, unlike water displacement which can introduce errors due to water adhesion and surface tension effects. This method enhances packaging integrity by providing consistent headspace control critical for product safety and shelf life in thermal processing.

Water Displacement Integrity Test (WDIT)

The Water Displacement Integrity Test (WDIT) offers a precise method for detecting leaks in packaging by submerging packages under water and observing bubble formation, which directly indicates compromised seals. Unlike boiling tests that rely on temperature-induced changes, WDIT provides a non-destructive and highly sensitive way to ensure product sterility and packaging reliability.

Boil-Induced Volume Fluctuations

Boil-induced volume fluctuations occur due to the expansion and vaporization of liquids during boiling, causing significant changes in package volume that can compromise integrity. In contrast, water displacement methods maintain a stable volume measurement by submerging the package, minimizing errors from thermal expansion and gas release.

Liquid Migration Barrier Zoning

Boiling creates a more uniform Liquid Migration Barrier Zoning compared to Water Displacement by effectively sealing packaging materials through heat-induced molecular realignment, which reduces permeability and prevents liquid migration. This thermal sealing process enhances the barrier properties, ensuring improved protection against contamination and prolonging shelf life in packaged products.

Boiling Point Package Flexure

Boiling point package flexure impacts the integrity of sealed containers by causing deformation due to vapor pressure buildup during heating, which can compromise product safety and shelf life. Water displacement methods avoid excessive flexure by utilizing a more controlled environment, reducing the risk of package failure in temperature-sensitive applications.

Boiling vs Water displacement for packaging. Infographic

cookingdiff.com

cookingdiff.com