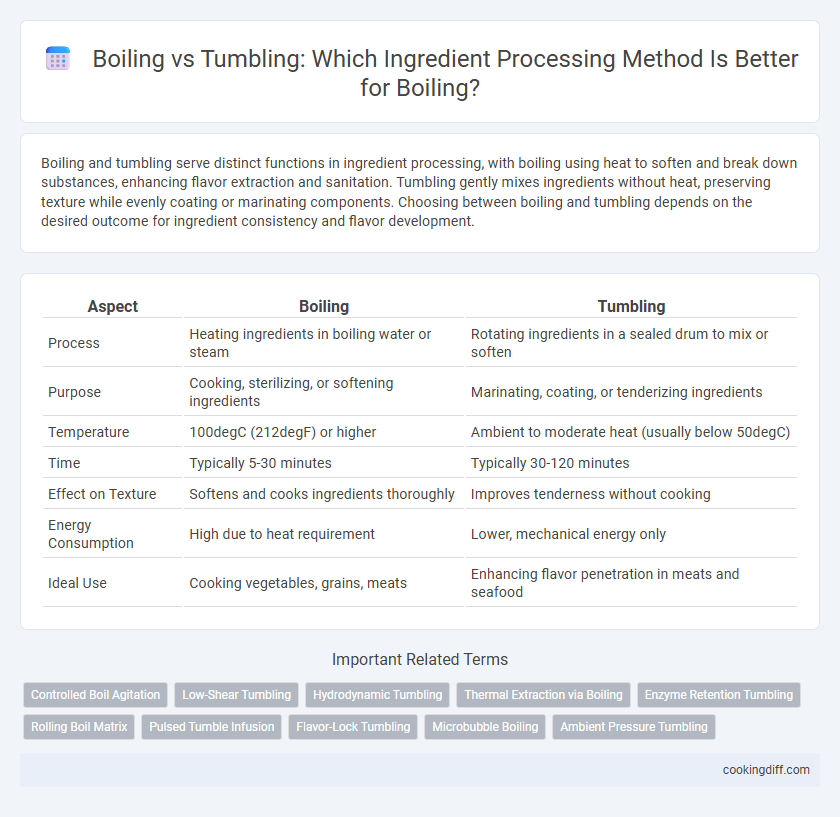

Boiling and tumbling serve distinct functions in ingredient processing, with boiling using heat to soften and break down substances, enhancing flavor extraction and sanitation. Tumbling gently mixes ingredients without heat, preserving texture while evenly coating or marinating components. Choosing between boiling and tumbling depends on the desired outcome for ingredient consistency and flavor development.

Table of Comparison

| Aspect | Boiling | Tumbling |

|---|---|---|

| Process | Heating ingredients in boiling water or steam | Rotating ingredients in a sealed drum to mix or soften |

| Purpose | Cooking, sterilizing, or softening ingredients | Marinating, coating, or tenderizing ingredients |

| Temperature | 100degC (212degF) or higher | Ambient to moderate heat (usually below 50degC) |

| Time | Typically 5-30 minutes | Typically 30-120 minutes |

| Effect on Texture | Softens and cooks ingredients thoroughly | Improves tenderness without cooking |

| Energy Consumption | High due to heat requirement | Lower, mechanical energy only |

| Ideal Use | Cooking vegetables, grains, meats | Enhancing flavor penetration in meats and seafood |

Introduction to Ingredient Processing Methods

Which method between boiling and tumbling is more effective for ingredient processing? Boiling uses heat to soften ingredients and enhance flavor extraction, while tumbling relies on mechanical action to evenly coat and mix ingredients. Choosing the right process depends on the desired texture and flavor profile of the final product.

Understanding Boiling: Principles and Process

Boiling is a heat transfer process where a liquid reaches its boiling point, producing vapor bubbles within the liquid. This method ensures the rapid softening or cooking of ingredients by subjecting them to temperatures of 100degC (212degF) or higher at atmospheric pressure.

- Heat Transfer Efficiency - Boiling delivers uniform heat through direct contact with the boiling liquid, promoting consistent ingredient processing.

- Temperature Control - Maintaining precise boiling temperatures ensures optimal texture and microbial safety without overprocessing.

- Process Speed - Boiling accelerates ingredient preparation by breaking down fibrous structures quickly compared to slower mechanical methods like tumbling.

What is Tumbling in Ingredient Preparation?

| Tumbling is a mechanical process used in ingredient preparation where ingredients are rotated gently in a drum or barrel to ensure uniform coating, mixing, or marinating without applying heat. This method preserves the texture, flavor, and nutritional content of sensitive ingredients compared to boiling, which uses heat to cook and soften ingredients. Tumbling enhances ingredient adhesion and flavor infusion, making it ideal for dry seasoning and delicate mixes in food processing. |

Key Differences: Boiling vs. Tumbling

Boiling uses high temperatures to cook ingredients by submerging them in water, while tumbling relies on mechanical agitation to mix and marinate ingredients without heat. Boiling alters texture through heat-induced breakdown, whereas tumbling preserves texture while enhancing flavor absorption.

- Heat Application - Boiling applies direct heat to cook ingredients, tumbling operates without heat.

- Texture Impact - Boiling softens and breaks down textures, tumbling maintains firmness and structure.

- Flavor Infusion - Tumbling promotes even distribution of marinades and spices, boiling infuses flavors through water extraction.

Choosing between boiling and tumbling depends on whether the priority is cooking or flavor integration in ingredient processing.

Effects on Texture and Flavor

Boiling softens ingredients by breaking down cell walls, resulting in a tender texture and a more diluted flavor profile due to flavor compounds leaching into the water. Tumbling, often used for meats and seafood, enhances texture through mechanical action that tenderizes while intensifying natural flavors by retaining juices within the ingredient.

Boiling can cause some loss of nutrients and subtle flavors, making it less ideal for delicate ingredients that require preservation of freshness. Tumbling promotes uniform seasoning and improves moisture retention, which enhances both mouthfeel and taste. This method is preferred for ingredients needing marination or fibrous breakdown without the dilution effects seen in boiling.

Nutrient Retention: Boiling vs. Tumbling

Boiling often results in significant nutrient loss, particularly water-soluble vitamins such as vitamin C and B-complex vitamins. Tumbling, by contrast, preserves more nutrients by minimizing exposure to heat and water during ingredient processing.

- Nutrient leaching in boiling - Water-soluble vitamins dissolve into boiling water, reducing the nutritional content of the ingredient.

- Minimal heat exposure in tumbling - Tumbling uses mechanical action with little to no heat, preserving heat-sensitive nutrients.

- Retention of phytochemicals - Tumbling maintains antioxidant levels better than boiling, which degrades these compounds through prolonged heat exposure.

Efficiency and Time Considerations

Boiling rapidly softens ingredients by applying direct heat, significantly reducing processing time compared to tumbling, which relies on mechanical agitation and can be slower. The high-temperature environment in boiling enhances efficiency by breaking down fibers swiftly, making it ideal for time-sensitive operations.

Tumbling offers gentler processing, preserving ingredient texture but requiring longer durations to achieve similar softness. While tumbling is less energy-intensive, boiling maximizes throughput in industrial settings where speed is critical.

Applications: When to Use Boiling or Tumbling

Boiling is ideal for ingredients requiring thorough cooking and softening, such as tough vegetables and grains, ensuring even heat distribution and sterilization. Tumbling is preferred for delicate items like spices or herbs, where gentle mixing enhances flavor absorption without breaking the structure. Choosing between boiling and tumbling depends on the desired texture and ingredient sensitivity during processing.

Pros and Cons of Each Method

Boiling effectively softens ingredients quickly, enhancing flavor release but can lead to nutrient loss and changes in texture. Tumbling preserves ingredient integrity and nutrients by using gentle mechanical agitation but often requires longer processing times and may not fully soften tougher ingredients. Each method offers distinct advantages depending on the desired outcome--boiling for speed and flavor infusion, tumbling for nutrient retention and texture maintenance.

Related Important Terms

Controlled Boil Agitation

Controlled Boil Agitation ensures uniform heat distribution and precise temperature control, enhancing the texture and flavor profiles of ingredients during processing. Unlike tumbling, this method reduces ingredient damage and nutrient loss by maintaining consistent agitation within a controlled boiling environment.

Low-Shear Tumbling

Low-shear tumbling preserves ingredient integrity by gently mixing components without the intense heat and agitation of boiling, maintaining texture and nutritional value. This method reduces protein denaturation and moisture loss, making it ideal for delicate or heat-sensitive ingredients compared to traditional boiling.

Hydrodynamic Tumbling

Hydrodynamic tumbling enhances ingredient processing by uniformly agitating materials in a liquid medium, ensuring thorough flavor absorption and consistent texture without the intense heat of boiling. This technique preserves delicate nutritional compounds and improves moisture retention, unlike boiling which can cause nutrient leaching and texture degradation.

Thermal Extraction via Boiling

Thermal extraction via boiling efficiently releases water-soluble compounds by applying sustained heat, enhancing flavor and nutrient extraction compared to mechanical tumbling. Boiling ensures thorough breakdown of cell walls, allowing deeper infusion and improved ingredient bioavailability.

Enzyme Retention Tumbling

Boiling significantly reduces enzyme retention in ingredients, leading to decreased nutritional value and functional properties, while tumbling preserves enzymatic activity by minimizing heat exposure. Enzyme retention during tumbling enhances ingredient quality, maintaining bioactive compounds essential for flavor and texture development.

Rolling Boil Matrix

Rolling boil matrix provides a consistent high-temperature environment that ensures thorough cooking and optimal ingredient texture, unlike tumbling, which primarily agitates without sustained heat application. The precise control of temperature in rolling boil processes enhances flavor extraction and ingredient uniformity, making it superior for complex formulations requiring exact thermal processing.

Pulsed Tumble Infusion

Pulsed Tumble Infusion enhances ingredient processing by combining gentle tumbling with intermittent pulsations, promoting even flavor extraction and faster infusion compared to traditional boiling methods. This technique preserves delicate compounds and reduces nutrient loss by avoiding prolonged exposure to high temperatures, making it ideal for delicate and complex ingredient profiles.

Flavor-Lock Tumbling

Flavor-Lock Tumbling enhances ingredient processing by gently rotating ingredients in a sealed container, ensuring even distribution of marinades and seasonings without the harsh heat exposure found in boiling. This method preserves natural flavors and textures, resulting in more vibrant and tender ingredients compared to traditional boiling, which can leach flavors and nutrients into the water.

Microbubble Boiling

Microbubble boiling enhances ingredient processing by generating uniform heat distribution and minimizing nutrient loss compared to traditional tumbling methods, which rely on mechanical agitation that can cause uneven cooking and texture degradation. The microbubble technique improves mass transfer efficiency and reduces processing time, resulting in higher product quality and retention of bioactive compounds.

Boiling vs Tumbling for ingredient processing. Infographic

cookingdiff.com

cookingdiff.com