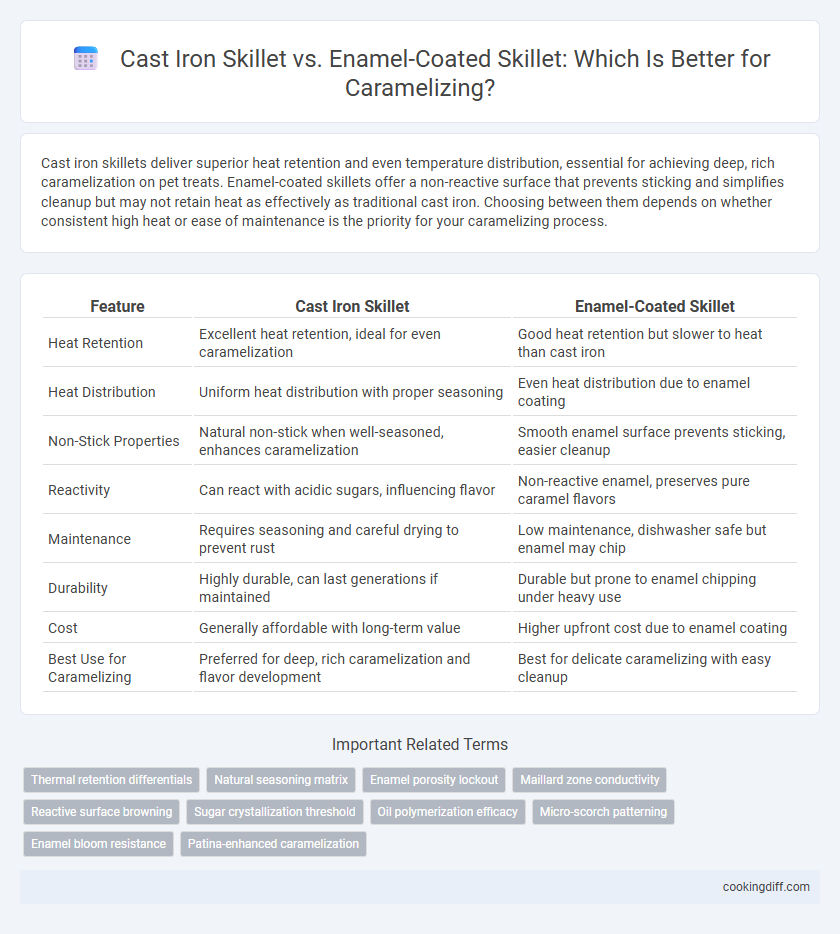

Cast iron skillets deliver superior heat retention and even temperature distribution, essential for achieving deep, rich caramelization on pet treats. Enamel-coated skillets offer a non-reactive surface that prevents sticking and simplifies cleanup but may not retain heat as effectively as traditional cast iron. Choosing between them depends on whether consistent high heat or ease of maintenance is the priority for your caramelizing process.

Table of Comparison

| Feature | Cast Iron Skillet | Enamel-Coated Skillet |

|---|---|---|

| Heat Retention | Excellent heat retention, ideal for even caramelization | Good heat retention but slower to heat than cast iron |

| Heat Distribution | Uniform heat distribution with proper seasoning | Even heat distribution due to enamel coating |

| Non-Stick Properties | Natural non-stick when well-seasoned, enhances caramelization | Smooth enamel surface prevents sticking, easier cleanup |

| Reactivity | Can react with acidic sugars, influencing flavor | Non-reactive enamel, preserves pure caramel flavors |

| Maintenance | Requires seasoning and careful drying to prevent rust | Low maintenance, dishwasher safe but enamel may chip |

| Durability | Highly durable, can last generations if maintained | Durable but prone to enamel chipping under heavy use |

| Cost | Generally affordable with long-term value | Higher upfront cost due to enamel coating |

| Best Use for Caramelizing | Preferred for deep, rich caramelization and flavor development | Best for delicate caramelizing with easy cleanup |

Introduction: The Art of Caramelizing

Caramelizing transforms natural sugars in food into deep, rich flavors through controlled heating. Choosing the right skillet enhances heat distribution and flavor development during this process.

- Cast iron skillet - Offers superior heat retention and even cooking, ideal for consistent caramelization.

- Enamel-coated skillet - Provides a non-reactive surface that prevents sticking and eases cleanup during caramelizing.

- Heat responsiveness - Cast iron heats slowly but maintains temperature longer, while enamel-coated skillets heat faster but cool down quickly.

What is Caramelizing?

Caramelizing is a cooking process that involves slowly heating sugar or food with natural sugars to develop a rich, deep flavor and golden-brown color. This chemical reaction, known as the Maillard reaction, enhances the sweetness and complexity of ingredients like onions and vegetables.

Cast iron skillets excel at caramelizing due to their excellent heat retention and even heating, which helps achieve a consistent, golden crust without burning. Enamel-coated skillets provide a non-reactive surface that prevents sticking but may heat less evenly, sometimes requiring careful temperature control. Both skillets offer unique advantages, with cast iron preferred for high-heat searing and enamel-coated for gentle caramelizing without metallic taste influence.

Cast Iron Skillet: Key Features

Cast iron skillets excel at caramelizing due to their superior heat retention and even heat distribution, which ensures consistent browning. Their naturally non-stick surface develops over time, enhancing the caramelization process without the risk of uneven cooking.

- Excellent Heat Retention - Cast iron holds and maintains high temperatures essential for perfect caramelization.

- Even Heat Distribution - The skillet's material distributes heat uniformly, preventing hot spots during cooking.

- Durable Natural Seasoning - The non-stick patina formed on cast iron improves with use, reducing food sticking.

Enamel-Coated Skillet: Key Features

| Surface Material | Enamel-coated skillets feature a smooth, non-porous glassy surface that resists sticking and facilitates even caramelization. This coating prevents food from reacting with the metal, maintaining flavor integrity during the high heat required for caramelizing sugars. |

| Heat Retention and Distribution | The enamel coating on cast iron skillets promotes consistent heat retention and distributes heat evenly across the surface, reducing hotspots that can cause uneven caramelization or burning. |

| Maintenance and Durability | Enamel-coated skillets require less seasoning and are easier to clean compared to bare cast iron, making them ideal for caramelizing sticky sugars without the risk of rust or metallic flavors. |

Heat Retention and Distribution Comparison

Cast iron skillets excel in heat retention, maintaining a consistent temperature ideal for even caramelization of sugars and meats. Their ability to evenly distribute heat across the surface prevents hot spots, ensuring uniform browning essential for perfect caramelization.

Enamel-coated skillets offer good heat distribution but generally retain heat less effectively than bare cast iron due to the enamel layer's insulating properties. This can lead to slower caramelization and the need for more precise temperature control to avoid uneven cooking or burning.

Reactivity with Ingredients

How does the reactivity of cast iron skillets compare to enamel-coated skillets when caramelizing? Cast iron skillets are reactive with acidic ingredients, which can affect the flavor and cause seasoning degradation during caramelization. Enamel-coated skillets provide a non-reactive surface, preserving the purity of caramel flavors and preventing metallic tastes.

Ease of Use and Maintenance

Cast iron skillets excel in heat retention and develop a natural non-stick surface over time, but they require regular seasoning and careful drying to prevent rust. Enamel-coated skillets offer easier maintenance with no seasoning needed and simple cleaning, but they can chip and are less tolerant to high heat variations. For caramelizing, enamel-coated skillets provide convenience, while cast iron demands more care but can enhance flavor through seasoning.

Flavor Development Differences

Cast iron skillets excel in caramelizing due to their superior heat retention and ability to create a consistent, high-temperature surface that promotes deep Maillard reactions, enhancing flavor complexity. Enamel-coated skillets provide more even heat distribution but may lack the intense searing capability necessary for developing rich, nuanced caramelized flavors.

- Heat Retention - Cast iron maintains high heat longer, allowing for more efficient caramelization and flavor development.

- Surface Interaction - The porous surface of cast iron promotes better browning and deeper caramel flavors compared to the smooth enamel coating.

- Heat Distribution - Enamel-coated skillets offer more uniform heating but might limit the depth of caramelization due to lower peak temperatures.

Choosing between cast iron and enamel-coated skillets significantly impacts the intensity and complexity of caramelized flavors in cooking.

Best Practices for Each Skillet Type

Cast iron skillets retain heat exceptionally well, providing even temperature essential for achieving deep, consistent caramelization. Preheat the skillet thoroughly and add a small amount of oil or butter to prevent sticking and ensure smooth browning.

Enamel-coated skillets offer easier cleanup and resist acidic ingredients but require moderate heat to avoid damaging the coating during caramelization. Use medium heat and avoid metal utensils to protect the enamel surface while slowly cooking sugars to a rich golden color.

Related Important Terms

Thermal retention differentials

Cast iron skillets provide superior thermal retention due to their dense material, ensuring even heat distribution crucial for consistent caramelization of sugars and food surfaces. Enamel-coated skillets, while offering easier maintenance, typically have slightly lower heat retention, which can lead to less stable temperatures and potentially uneven caramelization results.

Natural seasoning matrix

Cast iron skillets develop a natural seasoning matrix that enhances caramelization by providing superior heat retention and even cooking, which helps achieve a rich, deeply browned crust on sugars. Enamel-coated skillets, lacking this seasoning layer, offer easier maintenance but may not deliver the same depth of flavor or consistent caramelization due to less effective heat conductivity.

Enamel porosity lockout

Enamel-coated skillets offer a non-porous surface that prevents caramelized sugars from seeping into the material, ensuring easier clean-up and consistent browning. Unlike traditional cast iron, enamel's porosity lockout reduces the risk of absorbed flavors and staining, making it ideal for delicate caramelization processes.

Maillard zone conductivity

Cast iron skillets excel in caramelizing due to their superior heat retention and even conductivity within the Maillard reaction zone, promoting consistent browning. Enamel-coated skillets, while preventing sticking, often exhibit lower thermal conductivity, which can result in less uniform caramelization and slower Maillard reaction development.

Reactive surface browning

Cast iron skillets excel in reactive surface browning due to their ability to retain and distribute heat evenly, promoting deep caramelization and rich Maillard reactions. Enamel-coated skillets, while easier to clean and less reactive, may provide less intense browning as their non-reactive surfaces do not enhance the development of complex caramelized flavors.

Sugar crystallization threshold

Cast iron skillets excel in maintaining consistent high heat crucial for surpassing the sugar crystallization threshold during caramelizing, ensuring smooth, evenly browned caramel. Enamel-coated skillets, while easier to clean, often have slightly lower heat retention, which can increase the risk of uneven caramelization and premature crystallization of sugar.

Oil polymerization efficacy

Cast iron skillets promote superior oil polymerization due to their high heat retention and slightly rough surface, enhancing caramelization through a durable seasoning layer that intensifies flavor. Enamel-coated skillets, while easier to clean and resistant to rust, have a smoother surface and lower heat retention, resulting in less effective oil polymerization and a milder caramelization process.

Micro-scorch patterning

Cast iron skillets create consistent micro-scorch patterning due to their porous surface, enhancing caramelization by promoting even browning and deeper flavor development. Enamel-coated skillets, with their smoother surface, tend to produce less micro-scorching, resulting in more uniform caramelization but with milder flavor intensity.

Enamel bloom resistance

Enamel-coated skillets offer superior enamel bloom resistance compared to cast iron skillets, maintaining a smooth, non-reactive surface ideal for consistent caramelization without discoloration. This durability preserves flavor integrity and aesthetic quality during high-heat cooking processes like caramelizing sugar and browning vegetables.

Cast iron skillet vs enamel-coated skillet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com