Traditional whisks provide consistent mixing and are ideal for evenly caramelizing sugars by preventing burning through steady agitation. Spiralizing whisks, with their unique shape, enhance aeration and speed up the caramelization process by incorporating air more efficiently. Choosing between the two depends on the desired texture and speed, with traditional whisks offering control and spiralizing whisks delivering faster results.

Table of Comparison

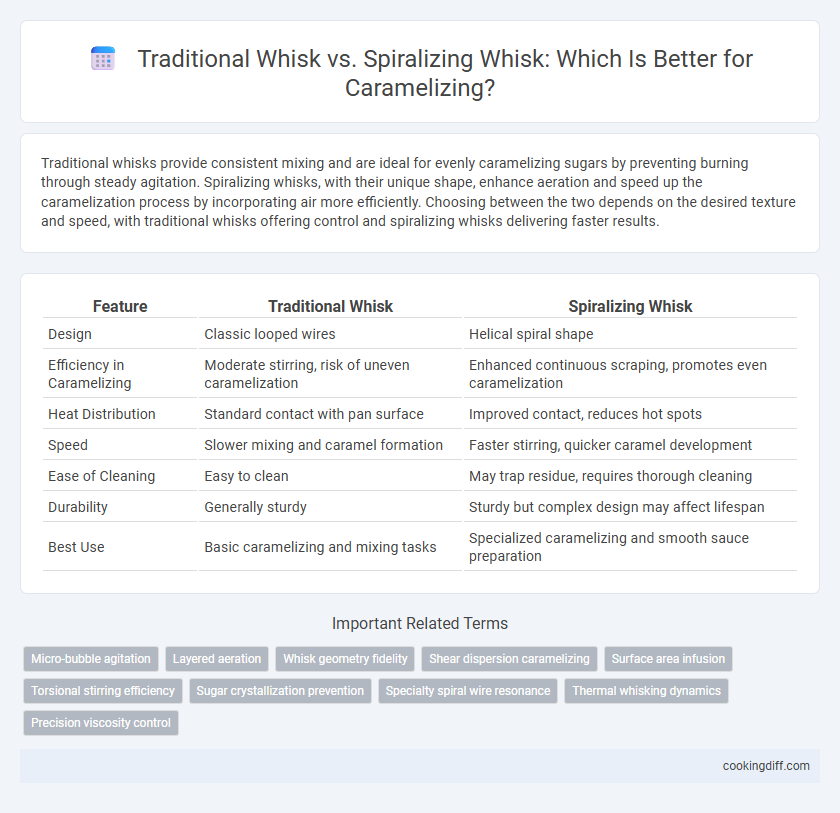

| Feature | Traditional Whisk | Spiralizing Whisk |

|---|---|---|

| Design | Classic looped wires | Helical spiral shape |

| Efficiency in Caramelizing | Moderate stirring, risk of uneven caramelization | Enhanced continuous scraping, promotes even caramelization |

| Heat Distribution | Standard contact with pan surface | Improved contact, reduces hot spots |

| Speed | Slower mixing and caramel formation | Faster stirring, quicker caramel development |

| Ease of Cleaning | Easy to clean | May trap residue, requires thorough cleaning |

| Durability | Generally sturdy | Sturdy but complex design may affect lifespan |

| Best Use | Basic caramelizing and mixing tasks | Specialized caramelizing and smooth sauce preparation |

Introduction to Caramelizing Techniques

Traditional whisks feature balloon-shaped wires that efficiently incorporate air and evenly blend sugar for smooth caramel bases. Spiralizing whisks, with their coil design, excel at reaching corners and preventing crystallization during caramelizing. Both tools enhance caramelization by promoting consistent heat distribution and texture control in sugar cooking.

What is a Traditional Whisk?

A traditional whisk features multiple looped wires that are joined at the handle, designed to incorporate air and blend ingredients smoothly. It excels in mixing batters, sauces, and creams without overworking the mixture.

When caramelizing, a traditional whisk ensures even stirring and prevents sugar from crystallizing by maintaining consistent heat distribution. Its flexibility allows gentle agitation, crucial for achieving smooth, golden caramel.

What is a Spiralizing Whisk?

A spiralizing whisk is a kitchen tool designed with coiled wires that effectively incorporate air when mixing ingredients, making it ideal for caramelizing sugar with precision. Its unique shape allows even heat distribution and smooth stirring, preventing sugar from burning.

Compared to a traditional whisk, the spiralizing whisk offers superior control over the caramelization process, ensuring a consistent texture and color. This whisk's design speeds up the melting and blending of sugar, enhancing the caramel's flavor and smoothness.

Key Differences: Traditional vs Spiralizing Whisk

The traditional whisk features a balloon shape ideal for aerating and blending caramel ingredients evenly, ensuring a smooth texture. Its wire loops provide consistent stirring, preventing burning during the caramelizing process.

The spiralizing whisk, designed with tightly coiled wires, excels at reaching the edges of the pan to scrape and incorporate sugar crystals effectively. This design reduces clumping and promotes even heat distribution, key for perfect caramelization. Unlike the traditional whisk, the spiralizing whisk minimizes the risk of crystallization by maintaining constant motion along the pan's surface.

Efficiency in Caramelizing Sugar

The spiralizing whisk promotes more consistent caramelization by allowing better circulation and even heat distribution in the sugar mixture. Traditional whisks tend to trap sugar in their loops, causing slower caramelization and increased risk of burning.

- Spiralizing whisk enhances efficiency - Its unique design continuously moves sugar particles, preventing clumping and accelerating caramelization.

- Traditional whisk limits heat contact - Sugar can get caught in the loops, slowing caramel formation and complicating stir control.

- Spiralizing whisk reduces sugar burning - Even stirring distributes heat uniformly, minimizing hotspots and caramel bitterness.

Heat Distribution and Control

Traditional whisks offer moderate heat distribution, requiring careful control to avoid uneven caramelization. Spiralizing whisks, with their unique design, enhance heat circulation for more consistent caramel texture.

- Traditional whisk - Provides basic heat distribution but can create hotspots that risk burning caramel.

- Spiralizing whisk - Promotes even heat flow, reducing the chance of crystallization during caramelizing.

- Heat control - Spiralizing whisks enable precise manipulation of caramel temperature for optimal browning.

Choosing the right whisk improves caramel quality by optimizing heat distribution and control.

Ease of Use and Handling

Which whisk is easier to handle when caramelizing, traditional or spiralizing? Traditional whisks are widely favored for their simplicity and familiarity, making them straightforward to maneuver during caramelization. Spiralizing whisks, designed with a unique coil shape, offer enhanced control and ease in reaching corners of the pot for uniform caramel cooking.

Cleaning and Maintenance Considerations

Traditional whisks typically have simple wire loops that can be easily rinsed and scrubbed, making cleanup after caramelizing straightforward. Spiralizing whisks feature intricate, coiled designs that may trap sticky caramel residues, requiring more thorough maintenance to ensure hygiene.

- Traditional whisk ease of cleaning - Smooth metal wires allow quick removal of caramel without extensive soaking.

- Spiralizing whisk residue buildup - Coiled shape can trap caramel, necessitating careful scrubbing or soaking.

- Maintenance durability - Both whisks generally withstand dishwasher cycles, but spiral designs need extra inspection to avoid hidden residue.

Best Applications for Each Whisk Type

The traditional whisk excels at stirring caramel over consistent heat, ensuring smooth, lump-free texture ideal for sauces and custards. The spiralizing whisk, with its unique coil design, efficiently incorporates air and reaches into corners, making it perfect for caramelizing sugar with minimal effort. For slow, even caramelization, the traditional whisk is best, while the spiral whisk is favored for quick, thorough mixing in complex recipes.

Related Important Terms

Micro-bubble agitation

Traditional whisks generate larger bubbles that can cause uneven caramelization and potential crystallization, whereas spiralizing whisks create finer micro-bubbles, enhancing heat transfer and promoting smooth, consistent caramel formation. Micro-bubble agitation improves uniform sugar melting and prevents scorching, making spiralizing whisks ideal for precise caramelizing processes.

Layered aeration

Traditional whisks create uniform aeration with consistent, small air bubbles ideal for smooth caramelizing, while spiralizing whisks generate layered aeration by incorporating varied bubble sizes that enhance texture complexity and prevent crystallization. The layered aeration from spiralizing whisks promotes even heat distribution and aids in achieving a rich, glossy caramel finish.

Whisk geometry fidelity

Traditional whisks feature a balloon-shaped geometry that provides broad surface agitation ideal for even caramelization but may trap sugar crystals, while spiralizing whisks offer narrow, looped wires that ensure precise stirring with higher geometry fidelity, reducing crystallization risks and promoting smoother caramel formation. The enhanced wire alignment and tension in spiralizing whisks create consistent heat distribution and more controlled sugar movement, optimizing caramel texture and gloss.

Shear dispersion caramelizing

Shear dispersion caramelizing benefits from a traditional whisk due to its ability to evenly incorporate heat and sugar through consistent, high-shear mixing, resulting in a smooth caramel texture without granulation. Spiralizing whisks provide less effective shear dispersion, often causing uneven heat distribution and potential sugar crystallization during the caramelization process.

Surface area infusion

The spiralizing whisk increases surface area contact with the caramel, promoting faster and more uniform infusion of heat compared to the traditional whisk. This enhanced surface interaction helps achieve a smoother, consistent caramel texture by preventing uneven cooking and reducing crystallization.

Torsional stirring efficiency

Traditional whisks offer moderate torsional stirring efficiency for caramelizing, but spiralizing whisks enhance the process by generating more consistent shear forces that evenly distribute heat and prevent burning. The spiral design promotes superior caramel formation through efficient mixing, reducing hotspots and significantly improving the texture and uniformity of the caramelized mixture.

Sugar crystallization prevention

Traditional whisks create a more vigorous agitation that can introduce air and promote sugar crystallization during caramelizing, while spiralizing whisks offer gentle, consistent stirring that minimizes crystallization risk by reducing sugar agitation. Using a spiralizing whisk enhances caramel texture by preventing premature grain formation, ensuring a smooth and glossy caramel finish.

Specialty spiral wire resonance

The specialty spiral wire resonance in a spiralizing whisk enhances caramelizing by creating uniform heat distribution and more efficient agitation of sugar crystals, leading to smoother and more consistent caramel textures compared to a traditional whisk. This optimized resonance minimizes crystallization and ensures quicker, even melting, making it ideal for precise caramelization processes.

Thermal whisking dynamics

Traditional whisks create broader, less consistent agitation that can lead to uneven heat distribution during caramelizing, while spiralizing whisks enhance thermal whisking dynamics by generating concentrated vortexes that promote uniform heat transfer and quicker sugar melting. The spiral design minimizes air incorporation and reduces crystallization risk, optimizing caramel texture and color development through precise thermal control.

Traditional whisk vs spiralizing whisk for caramelizing. Infographic

cookingdiff.com

cookingdiff.com