Coconut oil curing enhances wooden spoons by penetrating deeply, providing a natural barrier against moisture and preventing cracking. Tung oil curing creates a durable, water-resistant finish that hardens the wood surface and offers long-lasting protection. While coconut oil is food-safe and easier to apply regularly, tung oil delivers a tougher, more resilient coating ideal for heavy use.

Table of Comparison

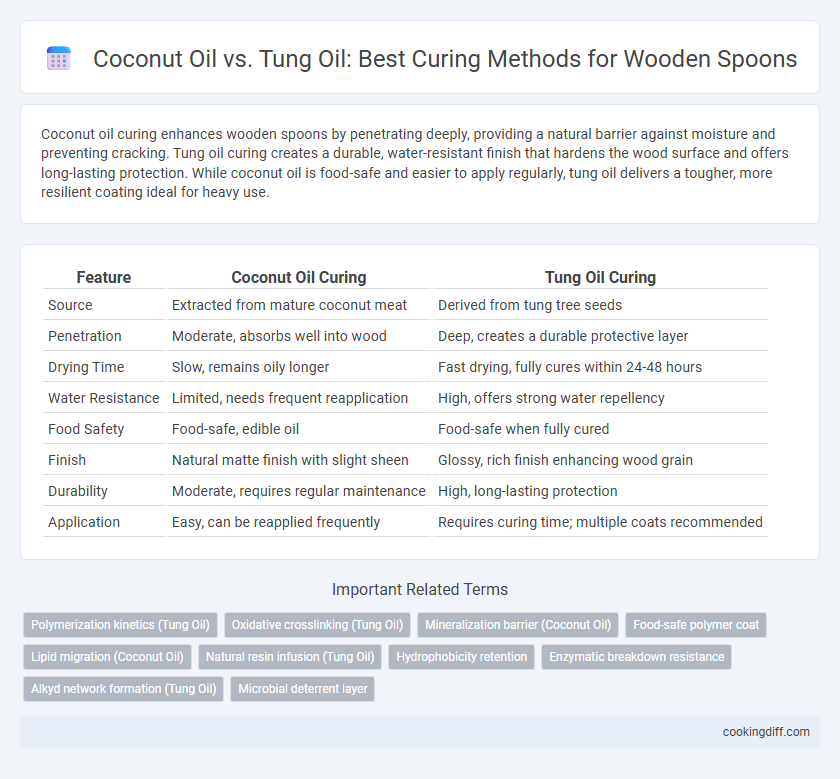

| Feature | Coconut Oil Curing | Tung Oil Curing |

|---|---|---|

| Source | Extracted from mature coconut meat | Derived from tung tree seeds |

| Penetration | Moderate, absorbs well into wood | Deep, creates a durable protective layer |

| Drying Time | Slow, remains oily longer | Fast drying, fully cures within 24-48 hours |

| Water Resistance | Limited, needs frequent reapplication | High, offers strong water repellency |

| Food Safety | Food-safe, edible oil | Food-safe when fully cured |

| Finish | Natural matte finish with slight sheen | Glossy, rich finish enhancing wood grain |

| Durability | Moderate, requires regular maintenance | High, long-lasting protection |

| Application | Easy, can be reapplied frequently | Requires curing time; multiple coats recommended |

Introduction to Wooden Spoon Curing

Curing wooden spoons enhances their durability and food safety by protecting the wood from moisture and bacterial growth. Coconut oil and tung oil are popular finishing options, each with unique properties suited for wooden utensil care.

- Coconut oil is a natural, food-safe option - it penetrates wood fibers to provide a moisturizing and water-resistant barrier.

- Tung oil offers a harder, more durable finish - it polymerizes upon exposure to air, creating a tough, protective coating.

- Choice depends on usage and maintenance - coconut oil requires more frequent reapplication, while tung oil cures to a longer-lasting finish.

Why Proper Curing Matters for Wooden Utensils

Why is proper curing important for wooden utensils like spoons? Proper curing with oils such as coconut oil or tung oil prevents wood from cracking and enhances water resistance, extending the utensil's lifespan. Tung oil offers superior durability and deeper penetration compared to coconut oil, making it more effective for long-term protection and maintaining the spoon's integrity.

Overview of Coconut Oil as a Cure

Coconut oil is a popular natural option for curing wooden spoons due to its ability to penetrate deeply and create a water-resistant barrier. Its high saturated fat content helps protect wood from cracking and drying out while being food-safe and non-toxic. Unlike tung oil, coconut oil cures faster but may require more frequent reapplication to maintain optimal wood protection.

Tung Oil: Traditional Wood Finishing Method

Tung oil is a traditional wood finishing method renowned for its deep penetration and water-resistant properties, making it ideal for curing wooden spoons. Unlike coconut oil, tung oil hardens upon exposure to air, providing a durable, protective layer that enhances the wood's natural grain.

Tung oil cures by polymerizing within the wood fibers, resulting in a long-lasting, food-safe finish that resists cracking and peeling. Its natural resistance to moisture and heat makes tung oil a preferred choice for wooden utensils used in cooking. This curing method requires multiple coats and adequate drying time to achieve optimal durability and aesthetic appeal.

Application Techniques: Coconut Oil vs Tung Oil

Coconut oil penetrates wood fibers quickly, providing a natural barrier that enhances moisture resistance, while tung oil forms a harder, more durable finish through polymerization when exposed to air. Application of coconut oil involves warming the oil for better absorption and requires frequent reapplication to maintain protection.

Tung oil cures by oxidizing and hardening over time, resulting in a more resilient surface that withstands wear and water damage, recommended for wooden spoons needing long-term durability. Applying tung oil requires multiple thin coats with adequate drying time between layers to achieve a smooth, protective finish.

Durability and Longevity: Comparative Analysis

Coconut oil curing enhances wooden spoons by penetrating deeply, creating a water-resistant barrier that improves durability and prevents cracking over time. The oil's natural antioxidants contribute to maintaining the wood's integrity, extending the spoon's lifespan effectively.

Tung oil curing forms a hard, protective polymerized layer on the wood surface, offering superior resistance to moisture and wear compared to coconut oil. This results in longer-lasting wooden spoons with enhanced toughness and reduced need for frequent reapplication.

Food Safety Considerations

Coconut oil is a popular choice for curing wooden spoons due to its natural antimicrobial properties, enhancing food safety by reducing bacterial growth. Tung oil, while durable and water-resistant, may contain additives that are not food-safe unless specifically labeled for culinary use.

- Coconut oil's antimicrobial effects - It helps inhibit bacterial growth, making wooden utensils safer for food contact.

- Tung oil's potential additives - Some formulations include chemicals that could be harmful if ingested, requiring careful selection of food-grade versions.

- Food-grade certification importance - Always choose oils labeled as food safe to ensure no toxic compounds contaminate cooking utensils.

Impact on Wood Appearance and Texture

Coconut oil imparts a rich, warm tone to wooden spoons, enhancing the natural grain while leaving a slightly glossy finish that highlights texture without overpowering it. Tung oil penetrates deeper into the wood fibers, creating a harder, more durable surface with a matte to satin finish that accentuates the wood's natural patterns. Both oils improve moisture resistance, but tung oil's polymerizing properties provide a longer-lasting protective layer compared to the softer, more easily absorbable coconut oil.

Maintenance and Reapplication Frequency

| Oil Type | Maintenance Requirements | Reapplication Frequency |

|---|---|---|

| Coconut Oil | Requires frequent maintenance to prevent rancidity and maintain a food-safe surface. | Needs reapplication every 1-2 weeks depending on use. |

| Tung Oil | Provides a durable, water-resistant finish that needs less frequent upkeep. | Reapplication recommended every 3-6 months to preserve protection and appearance. |

Related Important Terms

Polymerization kinetics (Tung Oil)

Tung oil exhibits faster polymerization kinetics compared to coconut oil, forming a harder and more durable finish on wooden spoons through oxidative cross-linking of its abundant unsaturated fatty acids. This accelerated curing process enhances water resistance and longevity, making tung oil a superior choice for preserving wooden utensils.

Oxidative crosslinking (Tung Oil)

Tung oil cures wooden spoons through oxidative crosslinking, forming a durable, water-resistant polymer network that enhances longevity and food safety. Coconut oil, by contrast, lacks this crosslinking ability, resulting in a less stable finish prone to rancidity and wear.

Mineralization barrier (Coconut Oil)

Coconut oil creates a mineralization barrier on wooden spoons by penetrating the wood fibers and polymerizing to form a durable, water-resistant layer that prevents moisture infiltration and bacterial growth. Tung oil also offers protection through polymerization but forms a harder, less flexible finish, potentially leading to cracking, whereas coconut oil maintains wood flexibility and long-term durability.

Food-safe polymer coat

Coconut oil creates a food-safe polymer coat by penetrating wood fibers and hardening upon exposure to air, offering a natural, non-toxic finish ideal for wooden spoons. Tung oil forms a more durable, water-resistant polymerized layer through oxidation, providing superior protection without compromising food safety in kitchen utensils.

Lipid migration (Coconut Oil)

Coconut oil curing for wooden spoons often results in significant lipid migration, causing a greasy surface and potential rancidity over time, which compromises the utensil's longevity and food safety. In contrast, tung oil polymerizes into a durable, non-migratory finish that enhances water resistance and preserves the wood without the drawbacks of lipid breakdown.

Natural resin infusion (Tung Oil)

Tung oil, a natural resin derived from the tung tree, penetrates wooden spoons deeply to provide superior water resistance and durability compared to coconut oil, which primarily acts as a surface conditioner. The resin infusion in tung oil creates a hard, protective layer that enhances the wood's longevity and prevents absorption of moisture and food residues, making it ideal for long-term curing of wooden kitchen utensils.

Hydrophobicity retention

Coconut oil curing enhances wooden spoons by providing superior hydrophobicity retention due to its saturated fat content, effectively repelling water and reducing absorption. Tung oil curing offers a durable polymerized finish but may allow slightly more moisture penetration over time compared to the more water-resistant barrier formed by coconut oil.

Enzymatic breakdown resistance

Coconut oil provides moderate enzymatic breakdown resistance for wooden spoons due to its saturated fats that inhibit microbial activity, while tung oil offers superior protection with its polymerizing unsaturated fatty acids forming a durable, water-resistant barrier against enzymatic degradation. Tung oil's curing process results in a harder, more resilient finish that extends the lifespan of wooden utensils compared to the softer, more permeable layer from coconut oil.

Alkyd network formation (Tung Oil)

Tung oil forms a robust alkyd network through oxidative polymerization, creating a durable, water-resistant coating ideal for wooden spoons. Coconut oil, primarily a triglyceride without alkyd formation, offers limited protection and tends to remain oily, lacking the hard, cross-linked film characteristic of tung oil cures.

Coconut oil cure vs tung oil curing for wooden spoons. Infographic

cookingdiff.com

cookingdiff.com