Smoke curing imparts a distinct smoky flavor and acts as a natural preservative by inhibiting bacterial growth through the deposition of antimicrobial compounds. Koji mold curing, on the other hand, utilizes Aspergillus oryzae to enzymatically break down proteins and fats, enhancing umami and tenderness while promoting fermentation's subtle complexity. Both methods influence charcuterie's texture and flavor, with smoke curing offering robust, smoky notes and koji mold curing delivering nuanced depth and improved digestibility.

Table of Comparison

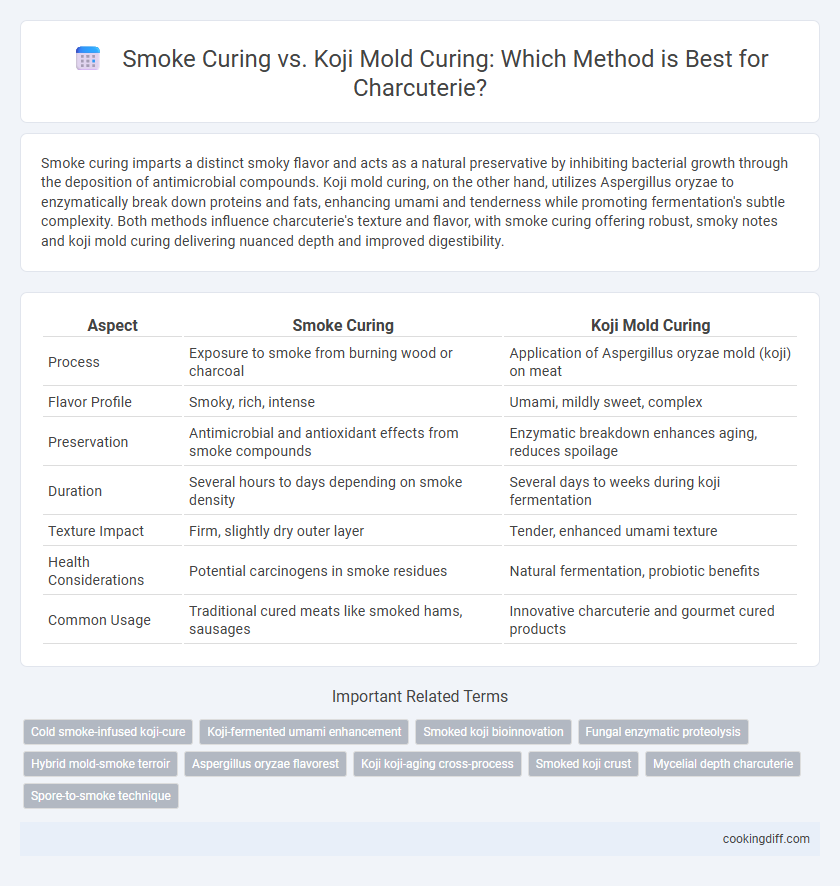

| Aspect | Smoke Curing | Koji Mold Curing |

|---|---|---|

| Process | Exposure to smoke from burning wood or charcoal | Application of Aspergillus oryzae mold (koji) on meat |

| Flavor Profile | Smoky, rich, intense | Umami, mildly sweet, complex |

| Preservation | Antimicrobial and antioxidant effects from smoke compounds | Enzymatic breakdown enhances aging, reduces spoilage |

| Duration | Several hours to days depending on smoke density | Several days to weeks during koji fermentation |

| Texture Impact | Firm, slightly dry outer layer | Tender, enhanced umami texture |

| Health Considerations | Potential carcinogens in smoke residues | Natural fermentation, probiotic benefits |

| Common Usage | Traditional cured meats like smoked hams, sausages | Innovative charcuterie and gourmet cured products |

Introduction to Smoke Curing and Koji Mold Curing

Smoke curing preserves charcuterie by exposing meat to wood smoke, which imparts distinct flavors and inhibits bacterial growth. Koji mold curing utilizes the enzyme-rich mold Aspergillus oryzae to ferment and tenderize meat, enhancing umami and texture naturally. Both methods offer unique preservation techniques that influence flavor profiles and shelf life in artisanal charcuterie production.

Historical Origins of Smoke Curing and Koji Mold Techniques

Smoke curing traces back to ancient civilizations where it was primarily used to preserve meats through exposure to smoke from burning wood, harnessing both antimicrobial and flavor-enhancing properties. This method became integral in cultures worldwide, evolving with regional woods and smoking techniques to create distinct charcuterie flavors.

Koji mold curing originates from East Asia, particularly Japan, where Aspergillus oryzae was cultivated to ferment rice, soybeans, and meats, introducing umami complexity and natural enzymatic tenderization. Historically, koji mold curing expanded from traditional sake and miso production to charcuterie, offering a biochemical alternative to smoke or salt-based preservation. The interaction of koji enzymes with proteins produces unique aromatic profiles, enhancing flavor without relying on smoke.

Fundamental Science Behind Smoke and Koji Curing

How do the fundamental scientific processes of smoke curing differ from those of koji mold curing in charcuterie? Smoke curing relies on the chemical infusion of phenols and formaldehyde from wood smoke, which act as antimicrobials and antioxidants to preserve and flavor the meat. Koji mold curing employs enzymatic activity from Aspergillus oryzae to break down proteins and fats into savory amino acids and fatty acids, creating unique umami-rich profiles while enhancing preservation through natural fermentation.

Flavor Profiles: Smoke vs Koji Mold in Charcuterie

Smoke curing imparts a robust, smoky flavor with deep, earthy undertones that enhance the savory profile of charcuterie. The phenolic compounds in smoke create a rich aroma and a slightly sweet, woody taste that intensifies with longer curing times.

Koji mold curing develops complex umami flavors through enzymatic breakdown of proteins and fats, resulting in a delicate, savory sweetness and subtle nuttiness. This fermentation method produces milder, more nuanced flavor notes compared to the bold, pronounced taste of smoke curing in charcuterie.

Texture Differences in Smoke-Cured vs Koji-Cured Meats

| Texture in Smoke-Cured Meats | Smoke-curing imparts a firm, slightly dry texture to charcuterie by dehydrating the surface and creating a smoky outer layer that enhances chewiness and preserves moisture inside. |

| Texture in Koji Mold-Cured Meats | Koji mold curing breaks down proteins and fats enzymatically resulting in a tender, velvety texture with a more delicate bite and enhanced umami flavor throughout the meat. |

| Comparative Texture Analysis | Smoke curing creates a denser and chewier charcuterie surface while koji curing produces softness and smoothness with consistent texture due to enzymatic action, influencing mouthfeel and slicing qualities. |

Health and Safety Considerations of Both Methods

Smoke curing involves exposing meat to smoke, which introduces carcinogenic compounds like polycyclic aromatic hydrocarbons that pose health risks, whereas koji mold curing uses Aspergillus oryzae, a safe fungus that enhances flavor without harmful byproducts. Both methods require strict hygiene and controlled environments to prevent contamination and ensure food safety in charcuterie production.

- Smoke curing risk - Prolonged smoke exposure can increase the concentration of carcinogens in the final product, raising health concerns.

- Koji mold safety - Koji mold is generally recognized as safe and contributes beneficial enzymes, reducing pathogen growth during curing.

- Sanitation importance - Both methods necessitate rigorous sanitation to avoid microbial contamination and ensure a safe charcuterie product.

Selecting curing methods with health and safety considerations in mind optimizes both product quality and consumer well-being.

Applications: Best Uses for Smoke and Koji Mold Curing

Smoke curing is ideal for imparting rich, smoky flavors and preserving meats through dehydration and antimicrobial compounds in the smoke. Koji mold curing excels at enhancing umami, breaking down proteins, and tenderizing charcuterie with enzymatic fermentation processes.

- Smoke curing for traditional cured meats - Best used for hams, bacon, and sausages requiring a robust smoky aroma and extended shelf life.

- Koji mold curing for dry-aged and artisanal charcuterie - Perfect for delicate flavor development and tender texture in prosciutto and specialty salamis.

- Combining smoke and koji curing - Sometimes applied sequentially to achieve complex flavor profiles and balanced preservation effects.

Required Equipment and Ingredients for Each Method

Smoke curing requires a smoker or smokehouse along with hardwood chips for producing the characteristic smoky flavor, while koji mold curing demands a controlled environment for koji propagation and specialized spores. Both methods rely on specific ingredients and equipment tailored to their unique curing processes to ensure optimal flavor development and preservation.

- Smoke Curing Equipment - Utilizes smokers or smokehouses with hardwood chips such as hickory or applewood to infuse meat with smoke flavor.

- Koji Mold Curing Equipment - Requires temperature and humidity-controlled chambers to cultivate Aspergillus oryzae spores on the meat surface.

- Essential Ingredients - Smoke curing uses cured meats and wood chips, whereas koji mold curing relies on koji spores, rice substrate, and precise environmental conditions for enzymatic action.

Step-by-Step Guide: Smoke Curing vs Koji Mold Curing

Smoke curing involves exposing meat to smoke from burning wood chips to infuse flavor and preserve it through antimicrobial properties, requiring careful control of temperature and smoke density over several hours or days. Koji mold curing uses Aspergillus oryzae spores to enzymatically break down proteins and fats, enhancing umami flavors and tenderizing the meat during a controlled fermentation period at specific humidity and temperature levels. Both methods demand precise monitoring of environmental conditions to ensure safety and achieve desired texture and flavor profiles for charcuterie.

Related Important Terms

Cold smoke-infused koji-cure

Cold smoke-infused koji curing combines traditional smoke flavor with enzymatic fermentation, enhancing charcuterie's depth and tenderness while inhibiting harmful bacteria without heat application. This hybrid method improves umami complexity and moisture retention compared to conventional smoke curing, offering a safer, more flavorful alternative in meat preservation.

Koji-fermented umami enhancement

Koji mold curing enhances charcuterie by promoting enzymatic breakdown of proteins and fats, resulting in a rich, savory umami profile distinct from traditional smoke curing. This fermentation process intensifies flavor complexity and tenderness while reducing reliance on smoky aroma, appealing to modern palates seeking nuanced taste layers.

Smoked koji bioinnovation

Smoke curing imparts deep, smoky flavors and natural preservation through wood smoke compounds, while koji mold curing employs Aspergillus oryzae to enzymatically tenderize and develop umami-rich profiles in charcuterie. Smoked koji bioinnovation combines these techniques by integrating smoke-infused koji cultures, enhancing flavor complexity and accelerating maturation with improved safety and sensory attributes.

Fungal enzymatic proteolysis

Smoke curing relies on phenolic compounds and antibacterial properties from wood smoke to preserve and flavor charcuterie, while koji mold curing utilizes fungal enzymatic proteolysis by Aspergillus oryzae to break down proteins into amino acids, developing complex umami flavors and tender texture. The proteolytic activity of koji mold enhances protein degradation more efficiently than smoke curing, resulting in superior flavor depth and optimized meat maturation.

Hybrid mold-smoke terroir

Hybrid mold-smoke terroir in charcuterie combines the traditional depth of smoke curing with the nuanced enzymatic fermentation of koji mold, creating complex flavor profiles rich in umami and earthy notes. This innovative curing technique enhances preservation by balancing antimicrobial smoke compounds with koji's mold-driven proteolysis, resulting in a unique sensory experience that reflects both microbial terroir and artisan smoke traditions.

Aspergillus oryzae flavorest

Smoke curing imparts a distinct smoky flavor and antimicrobial properties through phenolic compounds, while koji mold curing with Aspergillus oryzae flavorest enhances umami and sweetness by enzymatically breaking down proteins and fats in charcuterie. The Aspergillus oryzae flavorest strain optimizes fermentation, promoting complex flavor development and tender texture without the carcinogens associated with smoke curing.

Koji koji-aging cross-process

Koji mold curing in charcuterie utilizes Aspergillus oryzae to enzymatically break down proteins and fats, enhancing umami and tenderness beyond traditional smoke curing, which primarily imparts flavor through phenolic compounds. The koji-aging cross-process combines the enzymatic depth of koji fermentation with the aromatic complexity of smoke curing, creating uniquely textured and richly flavored meats that elevate artisanal charcuterie craftsmanship.

Smoked koji crust

Smoke curing imparts a distinctive smoky flavor and preserves charcuterie by infusing compounds like phenols and formaldehyde, while koji mold curing enhances umami through enzymatic breakdown of proteins and fats, resulting in complex flavor development. Smoked koji crust combines the benefits of both methods, creating a unique aromatic profile and natural preservation with enhanced texture and depth in artisanal charcuterie.

Mycelial depth charcuterie

Smoke curing penetrates charcuterie surfaces to a shallow depth, imparting flavor primarily through surface deposition of phenolic compounds and creating a protective antimicrobial layer. Koji mold curing utilizes the mycelial network that deeply infiltrates the meat, enzymatically breaking down proteins and fats to develop complex umami flavors and tender textures beyond the surface.

Smoke curing vs koji mold curing for charcuterie. Infographic

cookingdiff.com

cookingdiff.com